What you need to know about inventory management KPIs

Regular inventory KPI audits are essential to the growth and quality of your business. Read on how you can streamline operations and optimize performance using key data tracking and analytics.

Ioana Neamt

Achieving a desired level of performance is one thing, but sustaining that performance means a particular kind of long-term steady work: tracking. In inventory management, as with any other objective, it means tracking an assortment of metrics that might vary depending on the particularities of your business and/or your inventory. It is important that you identify the key performance indicators — or KPIs — that you need to pay special attention to when assessing the running quality of your inventory management.

Understanding inventory KPIs

KPIs for inventory management, in essence, are values that you can measure to help you track the efficiency and effectiveness of your inventory management practices and systems. Inventory KPIs provide valuable insights into how well you are managing your company’s stock levels, costs, and overall performance.

Over time, this tracking can help you identify and understand trends, benchmark your performance compared to the standards of the industry in which your business operates, and see where and how you could improve your operations.

Can inventory KPIs help you reduce costs and improve profits?

The short answer is yes, they can. Tracking and analyzing key metrics of your operations helps you understand your business on a deeper level. This translates to insights that you can better base decisions on, especially decisions on operational strategies.

In turn, identifying and implementing the best practices for your business and possible improvements and optimizations contribute significantly to reducing costs and increasing profitability.

Examples of inventory KPIs

KPI insights work together to give you an in-depth picture of how your operation is performing overall, as well as in individual segments. Below, we present some of the key indicators that you can track to identify areas where you can improve your management processes, reduce inventory costs, improve customer satisfaction, and increase sales.

- Inventory turnover rate

- Days sales in inventory (DSI)

- Days sales outstanding (DSO)

- Fill rate

- Sell-through rate

- Inventory accuracy

- Average inventory cost

- Shrinkage

- Backorder rate

1. Inventory turnover rate

Typically abbreviated to ITR, the inventory turnover rate measures how quickly or how many times you sell your inventory over a set period of time — for example, during the course of 12 months. If you find that your turnover rate is relatively high, this indicates that you are selling your inventory efficiently, and you are most likely not holding on to excess stock longer than you need to.

On the other hand, a lower turnover rate can mean that you are holding on to more inventory than is necessary. This can be a problem in terms of storage costs and possible depreciation of your inventory items. This KPI depends on the industry, of course, but a good inventory turnover rate is generally considered to be between 5 and 10.

2. Days sales in inventory

This KPI allows you to measure the average number of days that it takes your company to sell its entire inventory. In this case, you should aim for a lower value, as a lower number of days means you are turning your inventory over more quickly and moving your goods faster.

3. Days sales outstanding

In this case, you should also be aiming for a lower KPI value. DSO refers to the average number of days that it takes your company to collect payment from your customers. Therefore, a lower DSO means that you are efficient in collecting your receivables. Alternatively, you might identify collection issues and be in a better position to make some decisions that could improve your policies and procedures in this area.

4. Fill rate

Particularly significant in logistics and supply chain management, the inventory fill rate KPI refers to the percentage of customer orders that you can fulfill from your inventory without experiencing backorders or stockouts. A higher inventory fill rate means that your company is doing well in meeting customer demand and you are not losing any potential sales due to any lack of stock.

5. Sell-through rate

The sell-through rate is another indicator that helps you understand and evaluate your inventory strategy. Specifically, this refers to the percentage of inventory that you sell during a given period of time — typically a month or a quarter.

A higher sell-through rate indicates that your company is efficiently managing inventory and selling products relatively quickly — good in terms of carrying costs, cash flow, and increased profitability. On the other hand, a lower sell-through rate should alert you that you may be carrying too much excess inventory.

6. Inventory accuracy

This KPI is important for you to assess the quality of your inventory tracking. Inventory accuracy refers to the percentage of inventory records that are correct and it can show you whether you have good control over your inventory and if your records are reliable. Naturally, you want this KPI to score as high as possible, and one way of doing that is to have regular audits of inventory accuracy.

7. Average inventory cost

This key performance indicator can show you whether or not you are efficiently managing your inventory-related costs. Specifically, the average inventory cost KPI measures the average cost of carrying one unit of inventory. In this case, you should be aiming for a lower KPI reading.

If you find that you are incurring a higher average inventory cost, you might need to look at negotiating better deals with your suppliers, reducing your inventory levels, and reducing inventory shrinkage.

8. Shrinkage

Inventory shrinkage generally means goods that are lost. Whether it is the result of administrative errors, various damage, theft, or other reasons, it refers to inventory that came in but never made it to sale. The related shrinkage KPI gives you a measure of the amount of inventory lost during, for example, the course of 12 months.

Naturally, you will want this KPI to indicate the lowest amount possible, ideally zero, which would tell you that your business is in good control of your inventory.

9. Backorder rate

Another key indicator that helps you evaluate your performance in terms of meeting customer demand — the backorder rate. This KPI allows you to measure the percentage of orders that cannot be fulfilled immediately on account of the company not having enough stock on hand.

As with shrinkage, you’ll want this KPI to be a low reading, as you want very few to zero orders not being able to be fulfilled on time.

How do you best track inventory KPIs?

An essential tool for businesses of all sizes, KPIs for inventory management maximize your opportunity to evaluate your inventory management practices, identify what you could improve, and optimize your operations accordingly. Here are 3 basic steps to tracking your key performance indicators.

1. Identifying the inventory KPIs that are most relevant to you

Identifying the most important inventory KPIs for you to track will depend on several factors. As a general guideline, you’ll want to look at the specific goals of your business, the type of inventory you are tracking, and what data is available to you.

Inventory-related business goals include improving inventory turnover, reducing costs, or improving customer satisfaction. You will have to prioritize whatever the most appropriate KPIs are depending on which goal you want to evaluate.

The type of inventory you are managing also has an influence on what KPIs make more sense for your business to track. For instance, the inventory of a manufacturing business will need different KPI tracking than a wholesaler or a retail company.

Data, in itself, is key. You cannot measure what you don’t count, therefore, the KPIs you get to work with depend on what data you have. For instance, if you do not collect data on shrinkage, you cannot calculate that KPI. Once you have established what data sources you can work with, you can define your calculation methods.

2. Understand KPI benchmarks and perform regular audits

Any measurement you make needs to be compared to a reference that is relevant to your industry and your business. In other words, it is important to establish benchmarks for each of the KPIs you are tracking — educate yourself regarding what are high/low or good/bad values or measurements so that you know what further steps your audit calls for.

Perform your KPI audits at regular intervals. For best results, the appropriate interval might vary for some KPIs compared to others. Hence, you need to ensure you collect the necessary data continuously and don’t skip any audit terms.

3. Analyze and take appropriate action

Reviewing KPI data regularly allows you to identify any potential issues early on, test various means or strategies of improvement, and uncover new opportunities to grow your business.

In addition to operation optimization, it’s important to note that taking appropriate action can also refer to your KPI tracking itself — as your business goals evolve, you should review and refine your KPI process to make sure that you continue to get insights that are in line with your growth.

Understanding the potential consequences of poor inventory management

Poor inventory management carries a variety of risks that can significantly influence the bottom line and overall success of your business. Tracking KPIs relevant to your operations and goals can make a world of difference in your decisions and expectations.

In essence, inefficient management of inventory means there will be holes in your knowledge regarding your own operations. What you are not aware of, more often than not, ends up costing you. This can be in literal costs of carrying, storing, or losing inventory. Alternatively, it can be a relational cost, meaning you risk deteriorating the relationship between your business and your suppliers and/or customers.

For instance, stockouts can translate to missed sales opportunities, as most potential customers might not want to wait until their desired orders are back in stock. Frustrated customers can lead to a damaged reputation for your business. This can, in turn, end up affecting your negotiating power with existing or potential suppliers.

Ace inventory KPI audits with Katana

While there are obstacles down the line that nobody can see coming, such as KPI audits, Katana offers cloud inventory software you can leverage to be prepared for whatever challenges you face. Katana’s intuitive design packs a lot of features to help businesses manage their distributed inventory, whether within the country or even across the globe, including:

- End-to-end traceability with serial number, batch, and expiry date tracking

- Integration with other business tools, like Shopify and QuickBooks Online

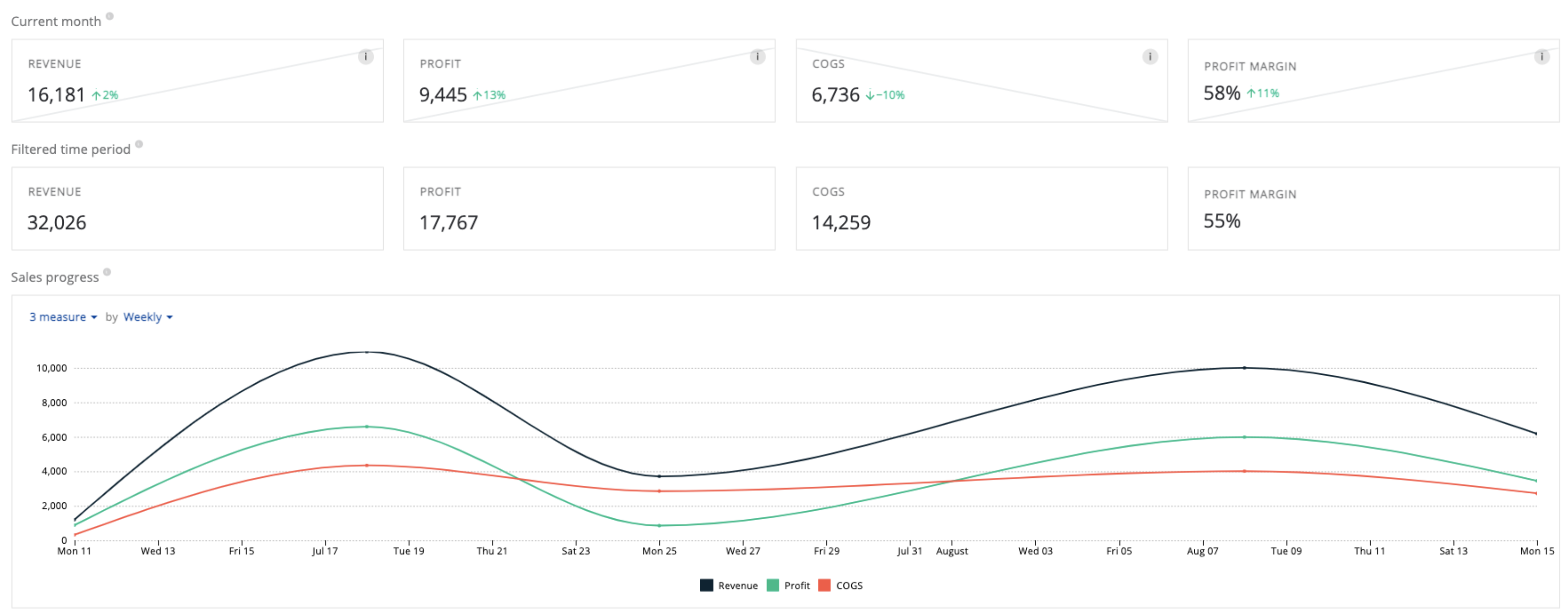

- Insights to track sales performance and other business KPIs

- Production planning and scheduling

- Barcode scanning for efficient stocktakes

Want to see it in action? Request a demo today.

Ioana Neamt

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control