Everything you need to know about excess inventory

No matter how well your inventory management system is optimized, mistakes will still be made.

Customer demand could fall well short of forecasts, production could accidentally run longer than supposed to, or you could get stuck with a product that’s difficult to sell. This can all lead to unwanted and unneeded inventory, otherwise known as excess inventory.

Excess inventory is a common issue in the manufacturing industry, but it’s not something you should ignore — it has significant implications for your business operations and bottom line.

In this article, we’ll at an excess inventory definition, how to spot it before it becomes an issue, and how to manage excess stock effectively.

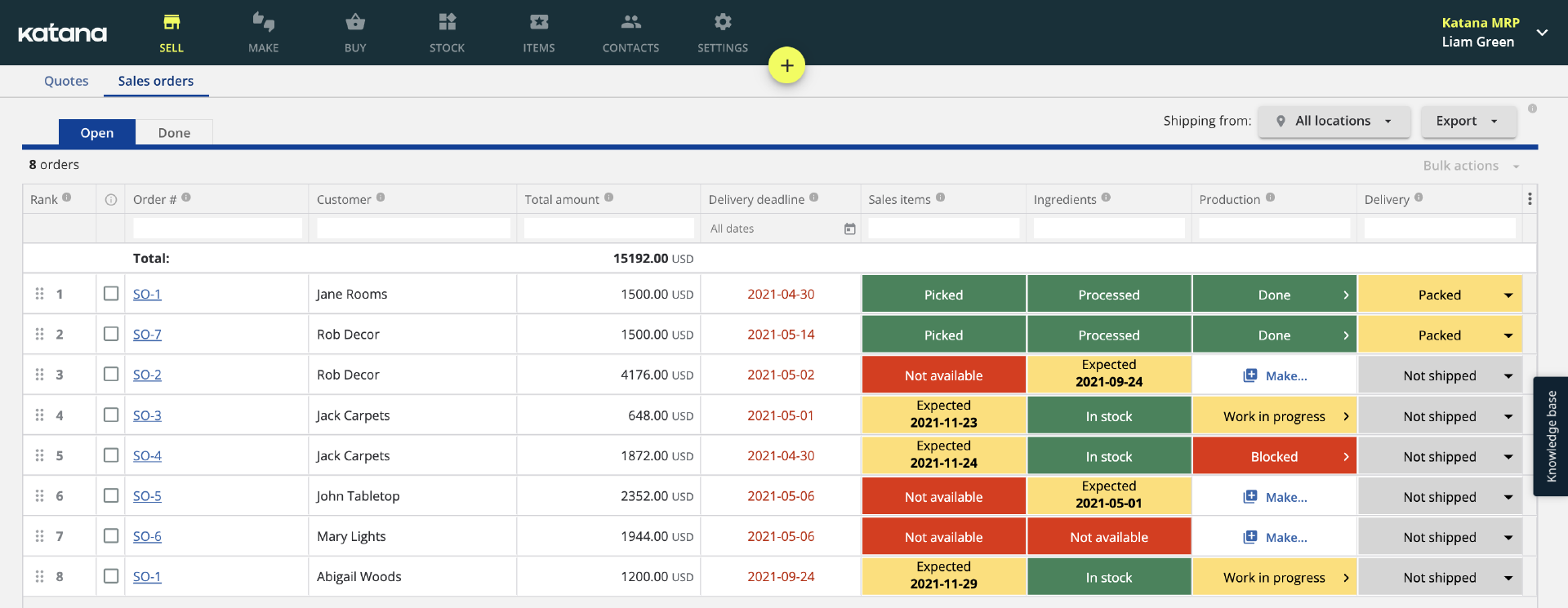

No more excess with inventory management software

Inventory management software like Katana gives you a real-time overview of your item movements throughout your entire supply chain.

What is excess inventory?

Excess inventory is any item a business has in excess of its immediate needs. It may be due to overproduction, overstocking, or simply an inability to sell the items quickly enough.

Whatever the case, excess products can cost businesses money if not properly managed. It ties up cash flow, occupies valuable warehouse space, and increases carrying costs and labor costs associated with managing it.

What causes excess stock?

Excess stock is caused by three main culprits:

- Customer demand

- Shipping delays

- Technical challenges

1. Customer demand

In manufacturing, companies must always be careful to forecast customer demand accurately. If the market is overestimated, companies are left with excess inventory that may be difficult to sell or even obsolete.

This is a delicate balance between ensuring you have enough stock to meet customer demand and not overstocking.

Some of the methods businesses can use to protect against overstocking include:

- Using a just-in-time inventory management system

- Performing regular stocktakes

- Making use of safety stock levels

- Utilizing demand forecasting software

With the right tools and processes, businesses can more accurately gauge customer demand, reducing the risk of excess inventory.

2. Shipping delays

Supply chain or shipping delays can also lead to excess inventory. If goods are delayed in transit, companies may purchase more stock than necessary to meet customer demand.

The term lead time describes the total time it takes for a product to be delivered from supplier to customer. To reduce the risk of excess inventory due to shipping delays, businesses can use lead time management tools that help them reach consistent levels of inventory accuracy.

3. Technical challenges

Any number of manufacturing challenges can lead to excess inventory. For example, production could run too long if machines are incorrectly set up or materials aren’t available in time.

E-commerce stores can be down for extended periods, preventing customers from making purchases. Factory power or network outages can also play a role in creating excess inventory.

These technical challenges can be difficult to anticipate, but businesses should do their best to take preventive steps and create contingency plans for when things go wrong.

How can you identify excess stock?

Identifying excess stock can be tricky, as it’s not always obvious what should be included. In basic terms, it is when you have too much inventory compared to projected customer demand.

If you are only expecting to sell 100 units in the next month and you already have 500 units in stock, then you have excessive inventory.

The best way to identify excess stock is to look at the inventory turnover ratio or the number of times an item is sold in a given period divided by its average inventory level. If this number drops significantly from one month to the next, it could indicate that you are holding too much stock and should take steps to reduce it.

What are the advantages and disadvantages of excess inventory?

While excess inventory can burden businesses, it also has advantages. For instance, excess inventory management can help protect against stock-outs and provide a cushion in times of unexpected customer demand.

It also allows companies to take advantage of promotional opportunities and special discounts that may arise due to overstocking.

These sales or discounts can sometimes increase brand awareness or customer satisfaction, believing you are rewarding their loyalty.

However, excessive inventory also has its drawbacks.

Limits cash flow

Excess inventory can limit cash flow because it ties up capital that could be used better. Instead of investing in new products or marketing strategies, companies are stuck with stock they don’t need and can’t sell.

This can be a death blow for small businesses that don’t have the capital to absorb losses from overstocking. Many companies have gone under just from investing too heavily in their inventory without being able to offload it.

Reduces storage space

When your warehouse is filled with excess inventory, it takes up valuable storage space that could be used for more profitable items. This limits the amount of stock you can keep on hand and can reduce your ability to react quickly to customer demands.

If your target market suddenly needs a new product, you may only be able to respond slowly if your storage space is taken up by excess inventory.

Increase labor costs

Not all products sit on a shelf without any attention. Some require regular maintenance or cleaning, which adds to your labor costs and reduces overall profitability.

It can also be challenging to keep track of excessive inventory, which requires more labor to ensure it is adequately monitored and accounted for. Inventory management programs can help streamline this process but still take time and resources.

Tips on how to manage extra inventory

If you find yourself with some extra inventory, there are a few steps you can take to manage it.

- 1. Identify — The first step is to identify precisely what items you have in excess and how many of each item. This will give you a better understanding of your situation and allow you to come up with a plan for dealing with it

- 2. Analyze — Once you’ve identified the excess stock, take some time to analyze the root cause so that you can avoid similar issues in the future

- 3. Discount — One way to move extra inventory quickly is by offering discounts or special offers on those items. This may help boost sales and reduce your inventory levels more quickly

- 4. Liquidate — If discounts aren’t doing the trick or if you have a large amount of excess inventory, consider selling it through a liquidator who specializes in buying and reselling bulk inventories

- 5. Donate — If you can’t sell your excess inventory, consider donating it to charity or other non-profit organizations that may be able to use it

Excess inventory can be a significant problem for any manufacturing business. However, with the right strategies and processes in place, it can be managed effectively.

By understanding what causes excess stock, keeping a close eye on customer demand, and using some of the tips above to manage it, you should be able to keep your excess inventory under control.

Take control of your entire inventory

Book a demo to get all your questions answered regarding Katana’s features, integrations, pricing, and more.

How can Katana help you avoid excess stock?

The best way to avoid excess stock is to be proactive. You can stay ahead of the game with a robust ERP system like Katana.

Katana helps you manage your stock levels more effectively by providing real-time data and insights into customer demand and production schedules. This means that you can adjust your orders in line with actual demand so you don’t end up with excess inventory.

As well as helping to prevent overstocking, Katana also makes tracking and managing existing inventories easier, allowing you to spot any potential issues quickly before they become a problem.

With powerful analytics tools and automated alerts, it’s easy to stay on top of your inventory and ensure you always have the right amount of stock on hand.

In short, Katana is designed to help you avoid excess inventory and maintain lean manufacturing across your entire business. With better visibility into your stock levels and production schedules, it’s much easier to anticipate potential problems before they arise — saving you time, effort, and money in the long run.

See Katana in action. Get a demo!

Excess inventory FAQs

What is excess inventory?

Excess inventory is any item a business has in excess of its immediate needs. It may be due to overproduction, overstocking, or simply an inability to sell the items quickly enough.

What happens to excess inventory?

Often, excess inventory will be sold at a discounted price to clear it out. However, if the item becomes obsolete, it may need to be disposed of instead, destroying any chance of revenue.

Why is it bad to have too much inventory on hand?

Too much inventory ties up cash flow, occupies valuable warehouse space, and increases storage costs and labor costs associated with managing it.

How can you avoid inventory excess?

The best way to avoid excess stock is to be proactive. With a powerful ERP system like Katana, you can stay ahead of the game by accurately forecasting customer demand and adjusting orders in line with actual demand.

How can you sell extra stock?

There are several ways to dispose of excess products. You can sell the items at a discounted price, return them to the supplier, donate them to charity, or use them as promotional materials. The key is finding the proper outlet for your extra stock that maximizes value.

Table of contents

Inventory Management Guide

More guides on inventory management

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control