Warehouse optimization or how to whip a warehouse into shape

Ioana Neamt

Nowadays, simple missteps or delays can disrupt warehouse inventory operations at the drop of a hat. Whether we’re talking minor glitches in your back-end logistics or a slight count hiccup, it’s enough to throw everything off course. And with it, throw a company’s reputation down the drain.

The guiding beacon in a sea of such hidden challenges? Warehouse optimization.

First things first, warehouse optimization isn’t just a buzzword. It’s a crucial strategy for companies aiming to pump up efficiency, slash costs, and keep up with the neverending competition.

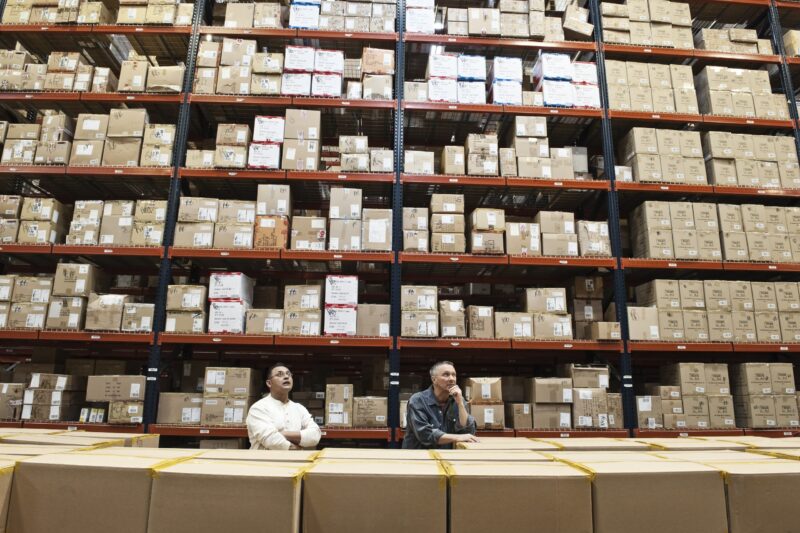

Warehouses have become the one place where efficiency, technology, and strategy all converge. Yet, a successful busy warehouse isn’t about its location or how many people work in it. It’s all about making it work better by improving the resources you have. And, like any other business, they need to change with the market. Sure, proper optimization takes time and planning, but with savvy optimization techniques, a company can unlock a treasure trove of benefits.

What is warehouse optimization?

Warehouse optimization is the one thing that can boost productivity, iron out workflows, and wow customers — all in one go. But, alas, it cannot be achieved with the flick of a magic wand. Rather, it’s an ongoing process that involves a lot of brains, a lot of hands at work, and a lot of fine-tuning.

Effective warehouse optimization relies on two buzzwords that are as repeated as they are relevant — efficiency and precision. Mixed with a proper warehouse management system (WMS), this trifecta is a game-changer that not only automates and streamlines processes, but also enhances business-wide communication.

At the end of the day, the goal of warehouse optimization is to make everything run like clockwork. This involves everything from streamlining operations, making the most of your space, managing inventory, and cutting costs, all the way up to keeping customers happy. Let’s find out more about how you can do that.

Warehouse optimization tips and strategies

Enhancing warehouse performance is complex, to say the least. The endeavor demands thorough and systematic strategies, but at least the math here is easy — boosting warehouse efficiency boosts productivity, which ends up boosting customer satisfaction.

It’s important to make your processes smoother and more reliable, which in turn leads to better overall performance and efficiency in your warehouse operations. Here are some quick tips to help you do that:

- Process standardization — Tasks like unloading, scheduling, and facility management should be streamlined as soon as possible. This saves time, cuts costs, and reduces errors.

- Clear communication — Good communication boosts productivity and reduces staff turnover. So make it a point to keep your team in the loop about goals, processes, and chances that might affect them.

- Employee engagement — While we’re at it, make sure to involve and empower your team as much as possible. A culture of inquiry and responsibility can pump up productivity and reduce employee dissatisfaction.

- Educated leadership — Employee engagement is driven by involved leaders. In the end, both have the same goal, which is to improve processes and services. Leaders in your organization must be taught to ask the right questions, how to make decisions, and how to take corrective action.

- Minimize inconsistencies — Consistent processes lead to more predictable outcomes. Simply put, when there is less variation, you can better anticipate results. This leads to fewer surprises and more reliable performance. Start by identifying key measures and working on minimizing their variability.

Following the above tips goes hand in hand with a set of strategies that aim to enhance your warehouse operations, lower costs, and boost overall efficiency. Outlined below are a set of strategies that can make or break your warehouse optimization plan:

- Prioritize staff safety — To say that safety is crucial in a busy warehouse would be an understatement. It all starts with clearing the aisles and making sure the walkways are free of spills and debris. Always provide your staff with the necessary cleaning tools to keep a tidy workspace. Also, invest in proper lighting to prevent accidents, as it can not only enhance visibility but also keep employees alert and reduce errors.

- Optimize your space — An efficient warehouse layout design goes a long way. Well-organized inventory and workstations can maximize the available space and even reduce the need for future expansion.

- Inspect consistently — A clean and well-organized warehouse environment can be achieved by establishing key performance indicators to measure critical aspects, such as order accuracy or picking speed. Remember that peak efficiency relies on regular visual inspections. This is why reviewing this type of performance data on a regular basis can help identify areas for improvement.

- Enhance training — Training programs are there to ensure that new hires are well-prepared. However, a more comprehensive approach should also include cross-training as well as regular training sessions to keep staff informed about new processes, technologies, and safety protocols.

- Embrace technology — Automation is an integral part of warehouse optimization in today’s post-COVID age. By integrating warehouse optimization software solutions like conveyor systems, barcode scanners, and even robots, you can speed up operations and reduce human error. Begin by investing in warehouse management systems that can help track inventory, manage orders, and optimize storage locations.

Benefits of warehouse optimization

Warehouse optimization isn’t just about making the most of storage space and efficiency. Optimizing your warehouse can also lead to additional perks that can boost business performance and even customer satisfaction.

Check out the advantages of optimizing your entire warehouse management system:

- Improved stock visibility — A well-optimized warehouse offers you a clear insight into your inventory. This means easily identifying the products you have, their precise location, and the quantity on hand. This, in turn, minimizes the chances of overstocking or understocking, and helps in making smarter decisions when it comes to reorders and inventory rotation.

- Enhanced data tracking — Piggybacking on comprehensive inventory visibility, better tracking offers invaluable data on product demand and sales forecasts. RFID tags, serial numbers, and barcodes are a must for businesses that want to access real-time insights.

- Better forecasting — Accurate information about how much inventory you have and how much space you need to store it helps you fulfill orders more efficiently. It also helps understand which products are selling well and which ones aren’t. This results in fewer disruptions and delays.

- Streamlined operations — An optimized warehouse is crucial to ensuring every process operates at peak efficiency. Whether it’s receiving and storing items or dispatching orders, each step must be fine-tuned to minimize time and reduce waste.

- Faster order fulfillment — With less time spent on order dispatch, businesses can gain a competitive edge in a market where fast delivery times are paramount. Additionally, customers appreciate the swift processing of their orders, leading to enhanced user interest and brand loyalty.

Streamline your warehouse optimization efforts with Katana

Warehouse optimization revolves around an impeccable management of time, space, and resources within your warehouse. And, this is exactly what Katana thrives on.

If you’re looking for a reliable partner in your warehouse optimization journey, Katana is the one-stop shop that meets all your warehouse optimization software needs. Our optimization software offers a suite of features designed to boost visibility and efficiency and improve your inventory management processes.

Through savvy automation and careful planning, Katana can help you boost operational efficiency and elevate the satisfaction and experience of your customers. Book a demo and see for yourself!

FAQs

Warehouse optimization is all about making your warehouse work smarter. It involves maximizing the efficiency of every aspect of warehouse operations, from improving workflow, managing stock, and enhancing storage to making the most out of the layout itself.

Warehouse optimization helps businesses adapt to market demands more effectively, stay competitive, and provide great service to customers.

By maximizing efficiency, warehouse optimization enables faster order processing, reduced labor costs, and overall better productivity. Improved inventory management can also lead to better resource allocation, smoother workflows, fewer delays, and reduced costs overall. Not to mention that a quicker order fulfillment and fewer errors ultimately lead to an enhanced customer satisfaction.

When it comes to making the most of your warehouse space, vertical is typically the way to go. Use tall shelves and adjustable racks, while regularly tweaking your layout according to business and staff needs. Make it a point to seek your warehouse staff’s insight when it comes to improving the available physical space.

Ioana Neamt

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control