How to read manufacturing blueprints in production

Do you stare at the squiggles on the sheet, struggling to understand what it is you see? Using this article, you’ll learn how to read blueprints and understand them.

James Humphreys

It can be a lucrative business decision for a manufacturer to offer contract manufacturing to clients.

With the right agreement, contract manufacturing can be a steady flow of income for your business, and it puts to work any resources which would otherwise be idle. However, you might have one way of working, it doesn’t mean you can expect your client to follow the same workflow. They might have a particular vision for their product and send you detailed drawings of how to make it.

If you don’t know how to read manufacturing blueprints, how do you hope to get started and make this agreement work?

In this article, we look into how to read blueprints, so you can get started on firing up the production lines and get products shipped to clients.

What are manufacturing blueprints?

A blueprint is an engineering drawing or design that guides the production and building of a product.

These blueprints provide a designed process, specifications, standards, etc., which, when followed, will lead to the development, building, or production of a device or product. Creating an engineering drawing is an important step in any product development process, as it ensures that all aspects of the product are considered and accounted for. It would be challenging to produce a consistent, high-quality product without a blueprint.

There are many different types of engineering drawings, but they all share one common goal — to provide clear instructions on how to produce a product.

The most common type of blueprint is the engineering drawing, which provides detail drawings of every component of the product. Other blueprints, such as process flow charts and assembly diagrams, offer more general information on the manufacturing process. No matter what type of blueprint is used, all blueprints must be accurate and up to date.

They should be reviewed and updated regularly to reflect changes in the manufacturing process or the product itself.

Blueprints are living documents that should constantly evolve to keep up with the latest technology and best practices.

What are the 5 parts of a blueprint?

A blueprint is a two-dimensional representation of a three-dimensional item. Architects, engineers, and manufacturers use it to create a plan for a structure or product.

The five parts for being able to read a blueprint are:

- The title blocks

- The legend

- The grid

- The scale

- The notation

1. The title block

The title block contains essential information about the drawing.

These information blocks typically include the title of the drawing, the date it was created, the name of the creator, and any revision history. The title block contains a company logo or other branding elements. This information helps anyone who needs to use the drawing to understand its purpose and context.

For blueprint reading, here are the other types of blocks and what each block contains:

Revision block — a revision block is an area on a blueprint that indicates changes to the drawing. This allows the person reading the blueprint to identify which areas have been revised easily. Revision blocks typically contain information about the change, such as its date and who made it.

Tolerance block — a tolerance block is a portion of a blueprint that provides information about the acceptable range of variation for a particular dimension. Tolerance blocks are typically located near the dimensions they pertain to and often include upper and lower limits.

2. The legend

The legend is a key part of any manufacturing blueprint.

It provides essential information about the blueprint symbols, dimension lines, and colors used on the blueprint. This information is necessary for anyone who needs to interpret the blueprint. The legend typically includes the following information:

- The meaning of each blueprint symbol, line, and color used

- The scale of the blueprint

- The units of measurement used on the blueprint

- Any other relevant information that would help someone interpret the blueprint correctly

Without a legend, a blueprint would be harder to read and understand.

3. The grid

The grid is a fundamental part when looking to draw blueprints.

It provides a consistent, reliable framework for building the rest of the blueprint. Without the grid, blueprint reading would be little more than a collection of random parts and pieces. The grid consists of three key components:

- A network of horizontal and vertical blueprint lines that crisscross the page

- A series of evenly spaced dots that are placed along these dimension lines

- A series of numbers and letters that are assigned to specific locations within the grid

Together, these three components create a coordinate system that can be used to precisely locate any point on the page.

This is incredibly important in manufacturing, where even the slightest error can have disastrous consequences. The grid provides a reliable, consistent way to locate points on a blueprint.

4. The scale

The scale in a manufacturing blueprint is the ratio between the size of an object on the blueprint and the object’s actual size.

The scale is usually expressed as a fraction or a ratio, such as 1:10 or 1/10. This means that for every unit of measurement on the blueprint, there are 10 units of measurement on the actual object. The scale can also be expressed as a percentage, such as 10%.

This means that the object’s size on the blueprint is 10% of the actual size of the object.

Blueprint scales are used to ensure that objects are manufactured to the correct size. Three scales are commonly used in understanding blueprints:

- English scale

- Metric scale

- Architectural scale

The English scale is the most common scale used to draw blueprints.

It is based on the imperial measurement system, which uses inches and feet as its units of measurement. The English scale is typically expressed as a ratio, such as 1:12 or 1/12. This means that for every inch on the blueprint, there are 12 inches on the actual object.

The metric scale is based on the metric system of measurement, which uses meters and centimeters as its units of measurement. The metric scale is typically expressed as a percentage, such as 10%. This means that the object’s size on the blueprint is 10% of the actual size of the object.

The architectural scale is used to draw blueprints for buildings. It is based on architectural drawings, which use feet and inches as its units of measurement. The architectural scale is typically expressed as a ratio, such as 1:50 or 1/50.

5. The notation

Notation is a set of symbols and other markings used to convey information on blueprints and other technical drawings.

Reading engineering drawings typically includes various types of notations, such as dimensions, tolerances, surface finishes, raw materials specifications, and more. Knowing how to read and understand the notation on a manufacturing blueprint is essential for anyone who needs to interpret or use the drawing. With that in mind, let’s look at some of the most common types of notations that you’ll find on blueprints.

Dimensions

Dimensions are the most basic and essential type of notation on any blueprint or technical drawing.

It provides key information on the size, shape, and location of the various features shown on the drawing.

Surface finishes

Surface finishes are another important notation found on blueprints.

These symbols indicate the required finish for various surfaces on the part or product.

Tolerances

Tolerances are numerical values that specify the acceptable range of variation for a given dimension or feature when making an item.

They’re typically used to ensure that parts fit together correctly and function as intended.

Material specifications

Material specifications, which can also be referred to as a bill of materials (BOM), are a type of notation that provides information about the materials that should be used to make the part or product.

This includes information such as the required material grade, hardness, thickness, etc. These are just a few of the most common types of notations you’ll find on blueprints. By understanding what each type of notation means, you’ll be able to interpret the drawing correctly and ensure that the part or product is made properly.

Putting together a bill of materials?

A lot of information goes into a bill of materials, so why not automate some of the fuss? Online you can find free SKU generators that will help you track your raw materials and finished goods more easily.

How do you read blueprints for beginners?

To start reading blueprints, you’ll need to understand the different types of blueprint lines used and what they represent.

The three main types of lines are:

- Construction

- Dimension

- Object lines

Out of these different types of lines, construction lines are the heaviest and indicate walls, doors, and windows. Dimension lines are medium weight and give specific measurements for length, width, height, etc. Object lines are the thinnest and show objects like furniture or appliances.

Start by looking at the title block to read a blueprint, usually located in the bottom right-hand corner.

Here you can find the designer’s name, the creation date of the blueprint, and other information.

Next, take a look at the legend of the symbols, which is also usually located in the bottom right-hand corner. This will tell you what all the symbols on the blueprint represent. Once you know what all the lines and symbols mean, you can start reading the blueprint from left to right and top to bottom to get a general idea of the design.

You can use a scale ruler to measure dimensions and take notes to get more specific information.

With practice, you’ll be able to read blueprints like a pro.

Software to automate your manufacturing business

Now you have a better understanding of how to read manufacturing blueprints — the next step is starting production and creating the item.

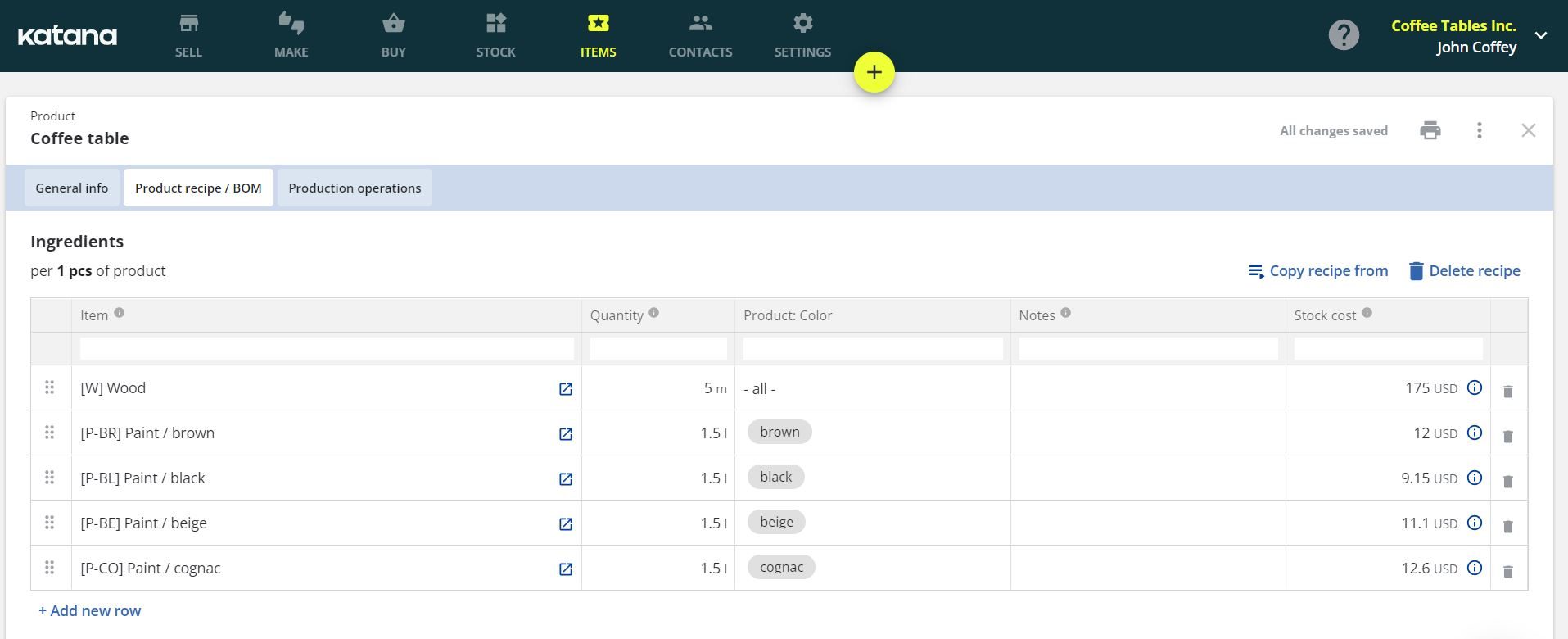

Katana cloud inventory software is an all-in-one platform for helping you carry out your production plans, from managing purchase orders to handling sales and improving your manufacturing lead time. Once you’ve received and read a manufacturing blueprint from a client, Katana will give you all the necessary tools you need to fulfill your project. Katana gives users access to:

- A real-time master production schedule

- Batch production and tracking features

- Reorder point notifications

- Multichannel inventory management

- Barcode scanning

- And so much more

Want to see how you can automate your manufacturing process with Katana? Reach out to our sales team and book a demo today,

James Humphreys

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control