Five profitable and easy things to weld and sell

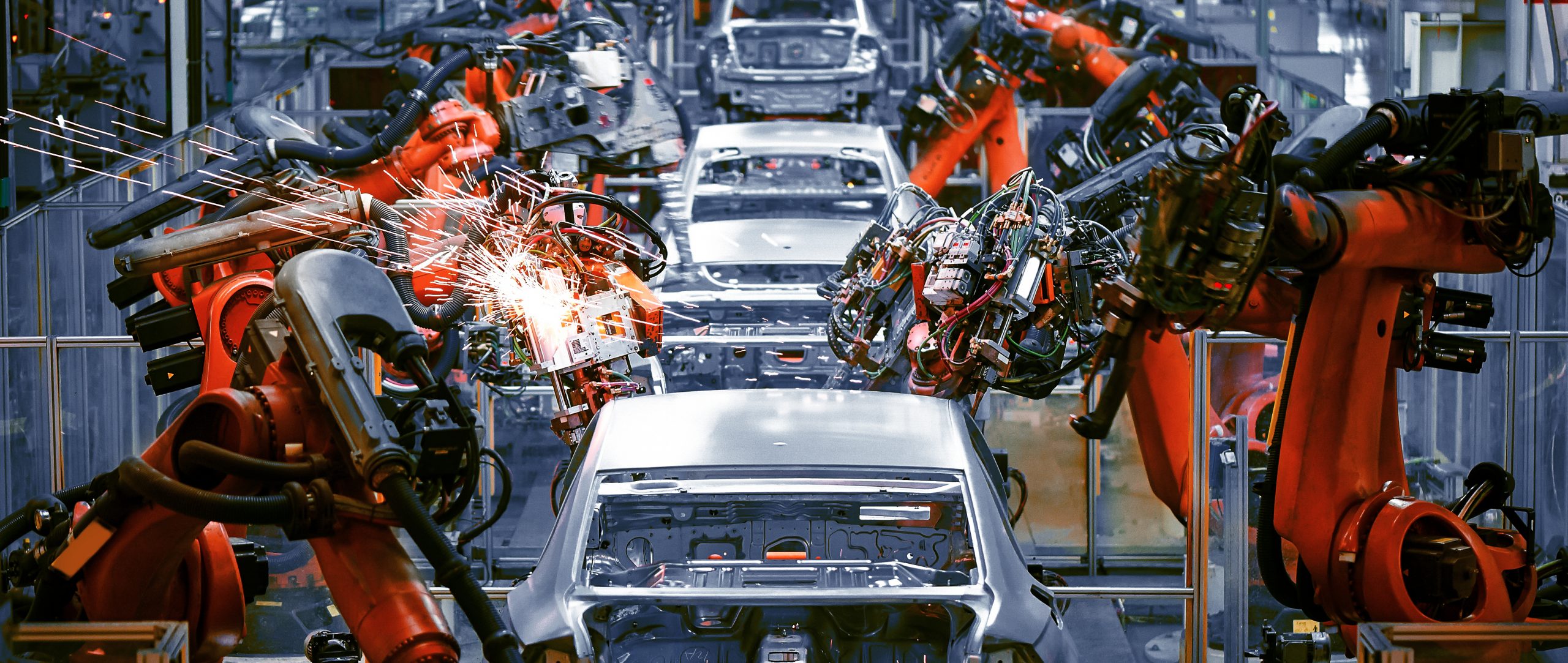

Welding dates back to the Iron Age, when the Egyptians first melted together pieces of metal to create strong joints. Today, you can use those skills to not only fuse your products but also make your customers stick to your brand.

Henry Kivimaa

Are you a welder looking for easy things to weld and sell? Or are you already running a business and want to find new product ideas? We’ve done the brainwork for you and gathered five simple ideas to make sparks fly between you and your customers. So grab your helmet, and let’s get welding!

What is welding?

Welding is a fabrication process that involves joining two or more pieces of metal or thermoplastics together by melting and fusing them. The materials are heated to their melting points, and a filler material — often a rod or wire — is added to the joint to create a molten pool. The molten pool then solidifies, creating a permanent bond between the two pieces.

There are many different types of welding, including:

- Arc welding — Uses an electric arc to melt and fuse metals together. The arc is created between an electrode and the base metal that’s being welded. The heat generated by the arc melts the base metal and the electrode, creating a molten pool that solidifies to form a strong joint when it cools.

- Gas welding — A flame produced by burning acetylene gas mixed with oxygen is used to melt and fuse metals together. A filler rod is usually added to the joint to help create a stronger bond.

- Resistance welding — An electric current is passed through two pieces of metal held together under pressure, causing them to heat up and melt at the contact point. The parts are then pressed together until they cool and fuse into one piece.

- Laser welding — Uses a high-powered laser beam focused on the area to be welded, which generates enough heat to melt and fuse metals together. It’s often used for particularly precise applications requiring high weld quality or in situations where access is limited.

Each technique has its advantages and disadvantages, depending on the application and used materials.

Welding is essential in many industries, including construction, manufacturing, automotive, and aerospace engineering. It creates robust and durable joints between metal components that would otherwise be impossible to achieve.

What does a welding business do?

Why is welding a risky business? Because welders mostly just make ends meet.

Now that that’s out of the way, there really is more to production welding than just helmets and sparks. Most businesses use welding for either of these two purposes:

- Repair

- Construction

But, as always, it’s good to plan your demand ahead, so the more expertise you have in both areas, the better your chances of creating a steady income.

Repair

Objects with a metal framework will sooner or later start bending, cracking, or falling apart. Instead of buying a new product, it may be more reasonable to fix the old one and still squeeze a few years of use out of it.

Welding repair is the process of fixing or restoring metal objects or structures that have been damaged or broken. This can include anything from repairing a cracked pipe to fixing a broken piece of machinery.

Welders use specialized equipment and techniques to cut, shape, and join metal pieces together in order to restore the object’s strength and functionality. Weld repairing requires skill, precision, and attention to detail to ensure that the repair is both effective and long-lasting.

With the right tools and expertise, welding repair can be a cost-effective way to extend the life of metal objects and keep them functioning properly for years to come. With the recent focus on reducing our ecological footprint with green manufacturing, repair of all types is on the rise, and people are increasingly looking into going more eco-friendly.

Solely focusing on repair welding can prove problematic since you’ll heavily depend on customer demand. That’s why it’s also recommended to construct some items for sale to guarantee a regular income.

Construction

Besides fixing old stuff, welding is also used to assemble brand-new products. Metal is a very durable material, and if the conditions are right and the item is ‘weld’ done, it can be utilized for years, if not decades.

Welding new products can include anything from building a custom car frame to fabricating a steel sculpture. Welders use various tools and methods to manipulate and bond metal pieces together in order to create the final product.

Production welding requires both creativity and technical skill. Successful welders must be able to create and read blueprints or design plans and have a keen eye for detail and an understanding of the different properties of various materials. They must also be able to work with precision and accuracy to ensure that the final product meets the required specifications and standards.

Welding new products can be a challenging but rewarding career path for those who enjoy working with their hands and have a passion for creating. With the proper training, experience, and equipment, metalworkers can bring their visions to life through the art of welding.

Forge a successful business with Katana

Book a demo to get all your questions answered regarding Katana’s features, integrations, pricing, and more.

5 easy things to weld and sell

Now that we’ve gone over what a welding business does let’s explore some easy things to weld and sell. There are unlimited ideas to choose from as long as you keep the customers’ interests at heart and deliver excellent quality. However, some products have proved to be crowd-pleasers.

Metal art

Metal art is a craft that involves using metal as the primary medium to create sculptures, decorative objects, and other decorative works. Metal artists use a variety of metalwork techniques, including welding, cutting, bending, and shaping, to manipulate metal into various forms.

Metal art can take many forms and styles, from abstract geometric shapes to delicate figurative sculptures. Some metal artists specialize in creating functional pieces, such as fancy furniture or lighting fixtures, while others focus on creating purely decorative pieces.

The beauty of metal art lies in its versatility and durability. Metal can be shaped and manipulated in so many ways that it allows for endless possibilities for creativity. Additionally, because metal is such a solid and durable material, metal art can last for generations when cared for properly.

Metal has been used throughout history to create everything from weapons and tools to ornate jewelry and religious artifacts. Today, metal artists continue to push the boundaries of what is possible with this versatile medium, creating stunning works of art that are both beautiful and functional.

Metal can also be combined with other materials, such as wood or textile, giving it a more subtle and natural look while still keeping the durability and strength of the construction. Depending on the style of the finished look, metal art can be displayed anywhere, making it a fun yet simple thing to weld and sell.

Furniture

Welding is also an excellent way to create custom furniture, such as tables, chairs, and benches. These items can be sold online or through local furniture stores.

Welded furniture is made using welding techniques to join metal pieces together. The items can be made from various metals, including steel, aluminum, and brass.

One of the benefits of welded furniture is its durability. Because it is made of metal, it can withstand a lot of wear and tear over time. Welded furniture can be very visually appealing, as the welds can become decorative elements in the design.

Additionally, other techniques and materials like woodworking or upholstering can be added to the piece to jazz up the look. This adds a more natural vibe and might make the items more suitable for the required interior style.

Overall, welded furniture offers a unique combination of strength, durability, and aesthetic appeal, making it a popular choice for those looking for functional yet stylish pieces for their home or office.

Garden decor

Welded garden decor is another popular niche that sells well at art fairs and online marketplaces. Examples include signs, plant stands, garden sculptures, and other decorative elements intended to enhance the beauty and functionality of a garden or outdoor space.

Again, one benefit of welded garden decor is its strength. An appropriately chosen and processed metal can withstand exposure to weather conditions without deteriorating over time. Wind and rain won’t do much to aluminum and steel constructions, while the sun will actually reveal a beautiful bonus — reflections depending on the position and angle of the light.

Welded decorations can also be custom-made to fit any garden or landscape design. This allows for a high degree of customization and creativity in the final product. Welded furniture makers often work closely with clients to ensure their vision is brought to life in the finished piece.

Garden decor can be functional or decorative. Functional decor, for example, trellises, bird feeders, and gazebos have a specific practical purpose. Decorative items, like sculptures and fountains, are meant to be enjoyed as visual additions to the garden, adding some life and personality to an otherwise natural landscape.

Although garden equipment is mostly considered summer goods, welded products endure cold weather and snow perfectly fine, making them also suitable for winter. Personal and unique metal decorations can spark up any front yard, bringing in customers all year round.

Sports equipment

Welded sports and outdoors training equipment can include gym items such as weightlifting bars, dumbbells, kettlebells, and other types of strength training equipment, as well as products for more active sports, like bike frames, skateboard decks, or parts for motorsports vehicles.

These products are typically made from steel or other metals that have been welded together to form a solid piece of equipment. Because the metal pieces are joined together through welding, they are less likely to break or bend under heavy use. This makes welded sports gear ideal for athletes who need reliable and long-lasting gear for their training routines.

Welded sports equipment can provide a safer option for athletes. Since the pieces are welded together, parts are less likely to come loose or break off during use, potentially causing an injury. Welded sporting goods can also be designed with safety features such as non-slip grips and secure locking mechanisms to reduce the risk of accidents further.

Another advantage of welded sports equipment is that it can be easier to maintain than other types of sports gear. Due to the metal pieces being fused together, there are no screws or bolts that need to be tightened or replaced over time. This can save athletes time and money on maintenance costs in the long run.

Sports and physical activity never go out of season. Even after the first New Year’s resolutions are broken, there are still plenty of people working on their buns of steel. Why not give them actual steel to work out with?

Custom car parts

Custom car parts can be a very fruitful business idea because who wouldn’t want to roll down their windows on the highway and blast heavy metal while riding a one-of-a-kind heavy metal wagon? For those with advanced welding skills and knowledge of auto mechanics, creating custom car parts such as roll cages or exhaust systems can be a lucrative business opportunity.

We can’t escape the strength and durability of metal materials in this section either. Welded car parts are a common feature in modern vehicles since they can withstand the stress of driving. Because of the strong bonding, welded car parts are less likely to break or come apart under usual driving conditions. This can improve the safety of the vehicle by reducing the risk of accidents caused by faulty or worn-out parts.

Additionally, welded car parts can provide cost savings over time. Because they are designed to last longer than other types of car parts, they don’t need to be replaced so often, which can save drivers money on maintenance costs in the long run.

Welded car parts can also be customized to fit specific needs or preferences. Manufacturers can create unique designs catering to different types of vehicles or driving styles. This allows for a high degree of personalization in the final product.

Overall, welded car parts offer numerous benefits for drivers looking for not only reliable and long-lasting but also unique and custom-made components for their vehicles. Improvements in welding technology have revolutionized the automotive industry by providing stronger and more durable options for all repair and customization needs.

How to manage weld manufacturing?

Implementing the right tools can streamline processes and increase efficiency throughout your operations. Here are some tips for successfully managing a welding business.

Automate tedious tasks

Manufacturing process automation can save time and money by eliminating manual processes such as data entry or document management. Use software to automate routine tasks so that you can focus on more essential aspects of running your business.

Improve safety and compliance

Welding is quite a dangerous process, so it’s crucial to make sure all procedures are thoroughly documented and followed at all times. Software solutions can help you ensure compliance with industry standards by providing clear instructions on completing tasks safely and efficiently.

Control costs more effectively

Track manufacturing costs in real time and maintain control over your budgeting process with production management software. This way, you’ll know exactly what is being spent and where, allowing you to stay within budget and avoid manufacturing waste while still achieving all of your goals.

Streamline operations

Create smoother workflows and help employees feel supported throughout the process by creating a better task management system. Avoid micromanaging and reduce miscommunications with automated assignments and real-time updates.

How can Katana benefit your welding business?

Katana is a cloud-based inventory software that helps thousands of businesses reach their goals. Here are some of the comprehensive features that Katana offers.

Live inventory tracking

Keep an eye on your metal supply and finished goods stock, all in one place. Control inventory levels, view order history, and optimize reordering processes with reorder points to remind you to refill your inventory.

Production scheduling

Create and assign tasks to your welders and shop-floor workers to streamline manufacturing. You can also prioritize the assignments based on customer demand, sales trends, and stock levels.

End-to-end traceability

Monitor your products, from supplies to finished goods, with lot tracking. In case of a recall, you can trace the products back to the original batch and track their retail journey.

Insights

Production, sales, and customer data help you keep an eye on the business statistics and navigate any spikes and drops in demand. Business is a numbers game, and Katana’s manufacturing analytics will help you stay ahead in that game.

Integrations

If you’re already using a tool you like or know of a feature you would like to integrate into Katana, feel free to fuse it into your workflow with the open API. There are also plenty of integrations partnered with Katana that you can use to create a custom workspace.

Build a solid business with Katana

Book a demo to get all your questions answered regarding Katana’s features, integrations, pricing, and more.

Henry Kivimaa

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control