What is shop floor management and what are its benefits?

Ioana Neamt

The need to keep a streamlined and flexible shop floor is crucial to businesses at any and all levels. Just ask Walter White. He definitely ran a tight ship when he was making all of his glassy blue-colored trinkets in that basement in Albuquerque all those years ago.

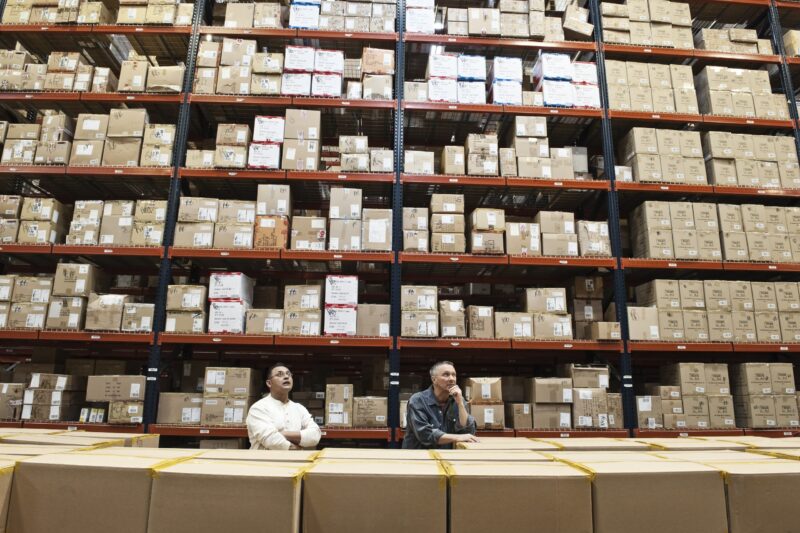

As production processes have become more and more complex and time-sensitive, shop floors need to evolve in order to meet these increasingly rising expectations. Machines and equipment are more sophisticated, the staff is more specialized, and the challenges posed by tight deadlines, high demand, and disrupted supply chains are more common. So, the need for highly optimized shop floors and the adoption of modern inventory management best practices are essential to a business’ success.

Read on to find out how shop floor management can help your business thrive and how you can boost efficiency with some easy steps and the right software.

What is shop floor management?

Shop floor management is an umbrella term for all the processes that go into optimizing activity in the production area of a business. Depending on the type of activities and tasks a business performs, shop floors may include:

- Machinery

- Equipment

- Raw goods

- Finished products

- Staff

As production mainly happens in this area, the shop floor is a key piece of the puzzle and any optimizations made in how it functions will impact the bottom line of any business.

Managing a shop floor can be done through the help of staff that have leading and organizing roles, but they will benefit a lot from having tools and software that can help their efforts. There are many things that go into the successful management of a shop floor, but one of the most important ones is data gathering and analysis. In order to make improvements to any process, you first need to fully understand its current status and the needs it has. Data-driven changes bring a higher level of confidence and they can be more targeted on certain aspects.

Besides data monitoring, there are a few other areas that can be the focus of a shop floor management system. We’ll go over some of the methods and objectives commonly set.

- Firstly, proper scheduling and workforce planning is an area that can benefit from applying these procedures, together with materials and production flows.

- Secondly, monitoring processes from start to finish becomes much easier, as well as finding hotspots for optimization opportunities. Any issues detected can be swiftly corrected so that productivity is improved at the same time.

- Thirdly, communication can get a big boost through the adoption of modern software and practices, which is crucial in these times of fast turnarounds and ever-changing consumer trends.

Now that we have broadly defined what shop floor management is, we will focus next on the benefits of careful shop floor management and optimization.

Why is shop floor management important?

We have already touched upon the importance of shop floor management, but let’s dive deeper into some of the benefits of the proper management of your production area. We selected just a few of the reasons why you should adopt these best practices for your business, but there are many more.

Improved efficiency and productivity

We’ll start with what’s likely the key benefit of shop floor management. Improving efficiency and productivity when it comes to production metrics will directly impact business results and revenue. Having transparent and real-time access to data pertaining to the shop floor will allow for changes that can shorten production times, reduce waste, and increase quality.

Usually, these goals are more easily reached when using inventory management software that caters to your exact business context and needs. Besides what the software offers, a great benefit will come from integrations that it allows with other applications and programs.

Reduced waste and errors

Though waste and mistakes cannot be eliminated completely, they can be reduced significantly with the right management software. Especially on the shop floor where production often takes place at a quick pace, errors can sneak in at any step. Quality can be improved greatly as processes are streamlined and protocols are designed to ensure rules are followed. Proper production scheduling and planning ensure that resources are efficiently used, avoiding shortages or oversupply.

Better communication

This benefit is closely connected to efficiency and productivity as communication is often what makes or breaks a successful team and project. Especially in today’s interconnected and fast paced business environments, the need for transparency and clear communication cannot be overstated.

The consequences of flawed communication and misunderstandings can be serious and long-lasting, so having software that enables your staff to communicate openly and clearly will allow them to be more productive on the shop floor. The benefits of effective communication are not felt only internally, but they extend to external partners who will be more satisfied and happy to do business with you.

Increased safety and predictability

The importance of safety on a production floor cannot be stressed enough even if it might not apply to the same extent for all businesses. But when adopting best practices in shop floor management, safety is boosted, and staff can be more in control of production. When you have a clear overview of what happens, you and your staff be in control of the shop floor. Being able to predict outcomes and changing needs on the floor will improve results and employee satisfaction at the same time.

Boost shop floor management efficiency with Katana

Katana offers a wealth of features designed to power businesses looking to optimize inventory management through real-time analytics, stock tracking, order management or inventory control. Through a wealth of integrations, the use cases for Katana software extend even further. From planning orders to forecasting inventory to managing resources and fulfilling orders, you can count on Katana to help your business grow.

Get a demo now and start reaping the benefits!

Shop floor management FAQs

Shop floor management refers to the organization and optimization of all processes that take place in the production area of a company, pertaining to staff, materials and goods, production processes, and more.

Shop floor management methods aim at optimizing workflows and staff schedules, improving production processes and communication on the floor, while spotting any errors quickly. Gathering data is another crucial goal, as it can inform improvements and enhance transparency.

There are many benefits to managing the shop floor efficiently, which include increased productivity, reduced waste and errors, improved communication, time savings, and enhanced safety on the floor.

Top inventory software will enhance your access to real-time tracking of the shop floor, allow you to optimize production schedules, and improve staff communication and organization.

Ioana Neamt

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control