Pet food manufacturing: how to get started

This article aims to give you an overview of the basics of the pet food manufacturing world, as well as some helpful information you’ll want to know if you plan on starting your own pet food business.

Erik Väli

We all love our pets.

And the best way to spoil them is to give them the highest quality food. Most pet owners you meet will swear by the traditional method of rewarding their pets with a treat every time a cute trick is performed. Cats and dogs love a good treat as much as we do — maybe even more.

Naturally, this means that the pet food industry is massive and a very rewarding business to be involved in.

But there are also many things you need to know before getting started on building your own manufacturing business. You’ll want to:

- Choose what kind of product you wish to produce

- Figure out how to make your business profitable

- Make sure your products are created to the best safety standards

- Manage your manufacturing needs in an organized and efficient way

In this article, we’ll cover exactly that.

How to start a pet product business?

Pet food is manufactured specifically for domesticated animals.

It is also manufactured with the animal’s specific nutritional needs in mind. The pet food manufacturing industry stretches all the way back to the mid-19th century and continues to evolve and innovate to this day. There are constant strides being made to create the healthiest products and bring in new flavors.

Starting a pet product business is actually not that different from starting any food product business. You have to:

- Come up with a brand

- An identity

- Find suppliers

- Make sure you reach the necessary health and safety standards

One of the first choices you have to make as a manufacturer is exactly what kind of products you will be producing.

Broadly speaking, cat and dog food is divided into wet and dry products — canned food with a higher moisture content and the other being kibble. Both come with their own benefits and drawbacks.

You want to find reliable suppliers for ingredients, such as animal-based products, grains, and cereals.

Beyond that, there are many similar considerations to making your pet food products stand out from the competition as there would be with other food products. For example, there is currently a demand for organic pet products due to increased awareness of pet health. Finding a way to stand out from the crowd is as important as with any other business.

Finally, you’ll want to go over the pet food regulations in your area to make sure your products are legal and safe to consume.

Is making pet food profitable?

When you consider how many people own pets, it is no surprise that the pet food manufacturing industry is very sizable. In 2021, the pet food market had an estimated value of around 94.76 billion. The largest market share is in America, with close to 50% of the global market.

The market for organic and premium pet products has been growing in Europe, and the Asia Pacific market has been seeing the most rapid growth in recent years.

The demand is unlikely to ever go anywhere, as obviously, people are always going to want to own pets. Add to that the fact that pet ownership has been on the rise since the Covid-19 pandemic. People are simply always going to want food for their pets.

Dog food accounts for close to half of the pet food industry, with the second biggest market share belonging to cat food.

Want to learn more about the state of manufacturing?

Not a fan of the slobber of dogs or the snobbiness of cats? Want to get into manufacturing but not sure what’s best for you? Be sure to check out the following articles that explore the current and future trends of manufacturing:

Pet food manufacturing process

Regulations for US pet food manufacturers

Be sure to read up on the AAFCO’s regulations, and the US Food and Drug Administration’s regulations.

In broad terms, however, the safety standards expected from pet food tend to be related to:

- Reliable suppliers

- Products must be free from harmful substances

- Products must be labeled truthfully and correctly

- Clear specifications when it comes to nutritional value, ingredients used, technical parameters, etc.

- Appropriate chemical analysis/studies to verify the nutritional content of the product

- Products meeting the same low-acid canning regulations as canned food made for human consumption

In essence, you can expect many of the same regulations and standards that you might find in food made for human consumption.

Dry pet food manufacturing

The dry pet food manufacturing process usually involves a cooking process that removes the fat from the meat components of the product. Other dry ingredients, such as the grains and cereals involved in the recipe, can also be added, dried, and sieved to create a dry mix.

The dry mix is then combined with the wet ingredients of the pet food and hydrated, creating a “dough”. The dough is then pressure cooked in an extruder. The dough is then extracted into “ribbons” in a specific shape.

At this point, they can be cut up and sliced into the sizes and shapes they are meant to be in, whether that’s kibbles or little dog treats. After this, the product is dried to remove any remaining moisture and to ensure it can be stored without spoiling.

Finally, the product is placed in a revolving drum, where it gets mixed with any last bits of flavoring and preservatives, giving the product its final delicious taste.

Wet pet food manufacturing

In the wet pet food manufacturing process, the product is actually normally cooked in the can (or another container) that it comes in when your customers buy it off the shelves. The ingredients are carefully measured and added into the container — this includes the animal products, such as meat, and often grains, thickening agents, vegetables, and extra vitamins and minerals). This has to be done in accordance with the recipe and the nutritional needs of the animal.

The container is then sealed, and the product is cooked within. The cooking process has to be highly regulated when it comes to temperature and the length of time the product is cooked to ensure the nutritional content, taste, and shelf-life of the product remain intact.

Once the product has been cooked, it is cooled, so it can finally be labeled and stored.

Dry vs wet pet food

After learning a bit more about the pet food manufacturing process for dry and wet products, you might be wondering — which is better? The truth is, both come with their advantages and disadvantages, so there isn’t really a clear answer. But let’s go over some of them to help you figure out the type of product you want to focus on and how you might want to market it to your customers.

First things first, both are potentially healthy options, so there are no worries there. Different dogs and cats might have different nutritional requirements and preferences. But ultimately, the most important part is the actual nutritional content of the product.

Advantages of dry pet food

The advantages of dry pet food are similar for both dogs and cats — dry pet food is easy to store and generally cheaper. Chewing helps sharpen a cat’s teeth, as well as helping keep dogs’ teeth clean. This can be especially helpful when fighting the gum problems faced by certain dog breeds.

Disadvantages of dry pet food

The disadvantage of dry pet food is that it can be harder to break down and chew for older pets or those breeds with weaker jaws and teeth. Its lower fat content might also prove a little insufficient for more active dogs.

Advantages of wet pet food

Wet pet food can help cats and dogs with hydration issues to a degree due to the higher moisture content. It is also said to help cats and dogs with certain urinary tract conditions. It is also common for dogs to prefer the taste of wet dog food.

Disadvantages of wet pet food

Wet pet food does not help clean a dog’s teeth quite as well as dry dog food does, and once a can has been opened, it tends to go off fairly quickly (so it can’t be stored quite as easily as dry products).

Using software for pet supplies manufacturing

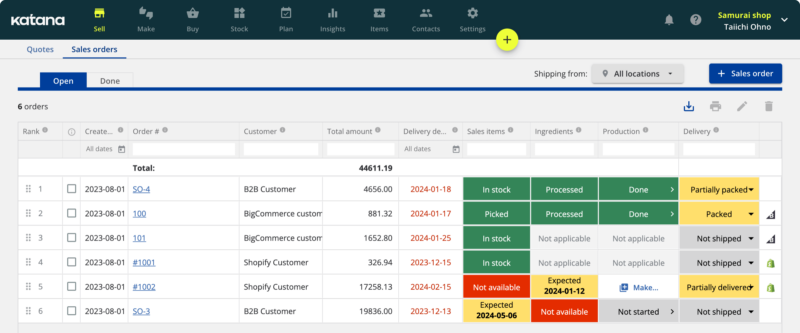

Handling any product made for consumption requires careful batch tracking and inventory management. Many pet food manufacturing business use software like Katana to help them achieve this.

Manage your pet food manufacturing needs with Katana

Regardless of whether you’re a seasoned manufacturer of pet products with a stable customer base, someone hoping to break into the industry, or a food distributor looking to expand their market, you’ll want the right food manufacturing ERP tools to manage your pet food manufacturing needs.

Katana’s cloud inventory software has already been tried and tested by businesses such as Puppy Cake. They used Katana to improve the efficiency of their day-to-day operations, manage their pet food inventory with the real-time master planner, and improve their production schedule.

You can read more about how Puppy Cake utilized Katana here.

Katana can also help with inventory batch and expiry date tracking, ensuring you can stay on top of your perishable stock. You can also automate transactions in your inventory and set up reorder points to order more items when the stock starts running low easily.

Thousands of pet food manufacturers have used Katana to build better businesses. Get started by booking a demo with Katana today.

Erik Väli

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control