Production planning ERP: streamlining efficiency for success

Discover the transformative potential of production planning ERP, as we explore its benefits, best practices, and top software solutions. Streamline your operations, boost efficiency, and unlock greater productivity with the power of ERP in production planning.

Henry Kivimaa

Efficient production planning is essential for companies to meet customer demands, optimize resources, and maximize profitability.

Enterprise resource planning (ERP) systems are software solutions designed to integrate and streamline various aspects of business operations. When applied to production planning, ERP provides a comprehensive solution that helps companies achieve operational excellence.

This blog post is about production planning ERP, exploring its significance, the benefits it brings, and best practices for implementation.

Whether you’re an industry veteran or new to the concept, join us as we uncover the transformative potential of production planning ERP and how it can revolutionize your organization’s production processes.

ERP in production planning

ERP systems have revolutionized the way businesses manage their operations across various departments.

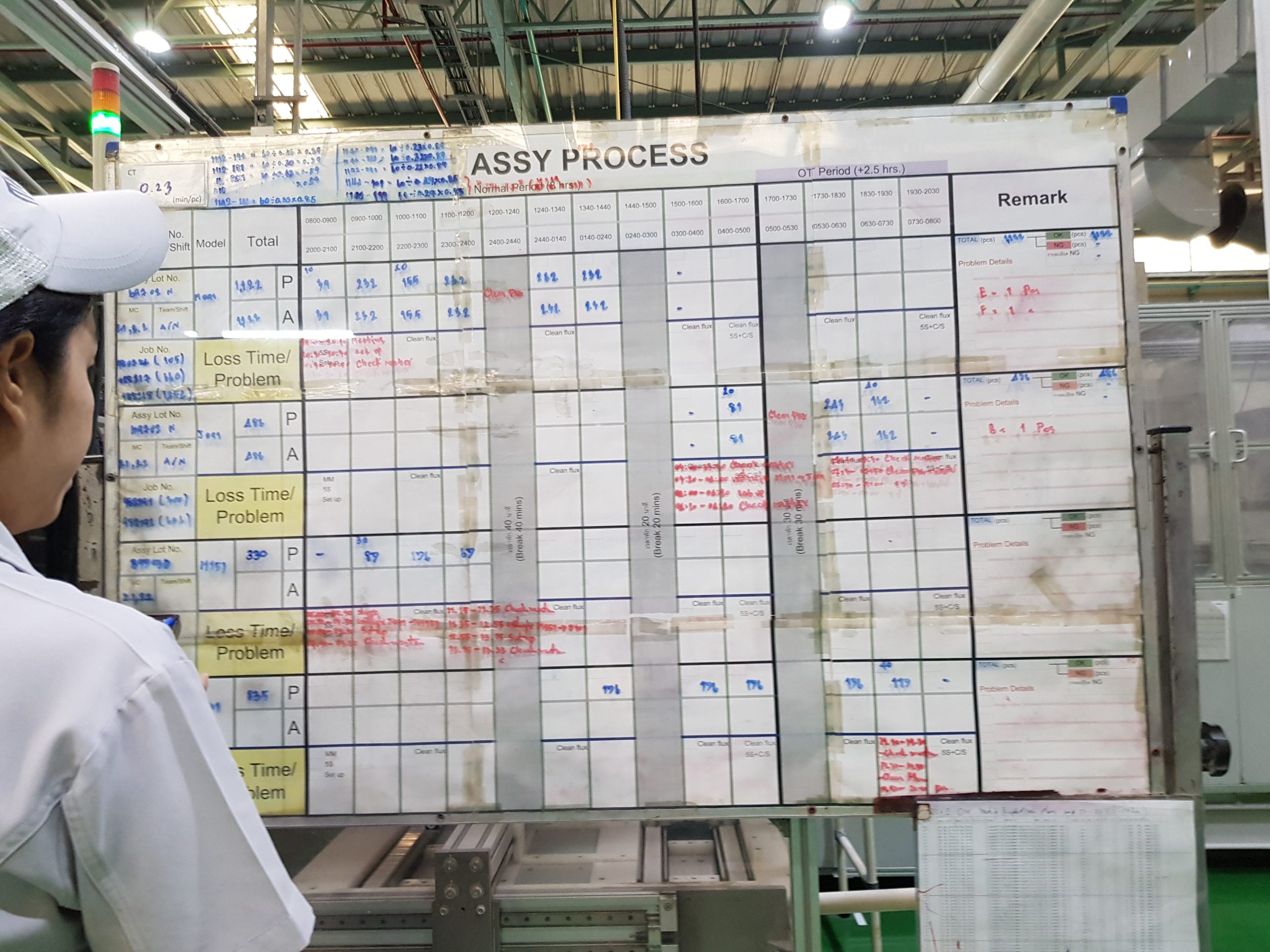

When it comes to production planning, ERP plays a crucial role in integrating and streamlining the entire process, from raw material procurement to final product delivery. By centralizing data, automating tasks, and providing real-time visibility, ERP empowers organizations to optimize their production planning activities and make informed decisions.

One of the key advantages of ERP in production planning is its ability to bring together different functions within an organization.

ERP serves as a central hub that connects departments such as inventory management, supply chain, finance, and customer relationship management. This integration ensures that information flows seamlessly across all stages of production planning, enabling efficient coordination and collaboration between teams.

Moreover, ERP provides a holistic view of production planning data, allowing stakeholders to monitor and control every aspect of the process.

Real-time insights into inventory levels, resource utilization, production schedules, and customer demand enable businesses to respond swiftly to changing market conditions. With accurate and up-to-date information at their fingertips, decision-makers can make data-driven choices to optimize production capacity, minimize bottlenecks, and ensure timely delivery of products to customers.

Additionally, ERP systems offer robust reporting and analytics capabilities.

These tools enable organizations to analyze production performance, identify inefficiencies, and implement continuous improvement initiatives. By leveraging ERP data, companies can uncover trends, forecast demand, and fine-tune their production planning strategies, leading to increased productivity and cost savings.

Download a free production scheduling template

If you want to schedule your production but are not quite ready to commit to an ERP solution, you can download this free production scheduling template to get started.

What are the benefits of production planning in ERP?

Production planning in the manufacturing industry can be incredibly complex, but using capable ERP software can greatly streamline the process. Let’s go over the 7 benefits production planning in ERP brings:

- Enhanced efficiency — With production planning integrated into ERP systems, businesses can streamline their production processes, automate tasks, and minimize errors, resulting in improved operational efficiency and productivity.

- Improved resource allocation — ERP systems provide accurate tracking and management of resources, including raw materials, equipment, and labor. By optimizing the allocation of these resources, organizations can prevent waste, avoid stockouts or overstocking, and ensure optimal utilization throughout the production cycle.

- Real-time visibility — Production planning in ERP offers real-time visibility into key production activities, such as inventory levels, production progress, order statuses, and customer demand. This visibility enables managers and stakeholders to make informed decisions, respond promptly to changes, and proactively address any potential bottlenecks or disruptions.

- Enhanced collaboration and communication — ERP facilitates seamless collaboration and communication between different departments involved in production planning. Cross-functional teams can easily share information, coordinate activities, and align their efforts towards common production goals, fostering better teamwork and reducing miscommunication.

- Accurate demand forecasting — ERP systems leverage historical data, market trends, and customer behavior analysis to accurately forecast demand. By having a clear understanding of future demand patterns, organizations can optimize production schedules, align inventory levels, and allocate resources effectively, avoiding stockouts, reducing excess inventory, and enhancing customer satisfaction.

- Quality control and compliance management — ERP systems provide robust tools for implementing standardized processes, tracking quality metrics, and ensuring compliance with industry regulations throughout the production cycle. This ensures consistent product quality, adherence to regulatory requirements, and minimizes the risk of non-compliance issues.

- Continuous improvement — By analyzing production planning data and performance metrics available in ERP systems, organizations can identify areas for improvement, uncover bottlenecks, and implement continuous improvement initiatives. This data-driven approach enables companies to refine their production strategies, optimize operational processes, and enhance overall performance over time.

To ensure you can get the maximum benefits, there are some best practices you should follow. Next, we’ll take a closer look at these.

Best practices for production planning in ERP

Below you’ll find the 10 best practices that help you get the most out of your ERP for production planning.

1. Ensure data accuracy and integrity

Maintain accurate, complete, and up-to-date data within the ERP system. Regularly validate and reconcile data to ensure its integrity. Inaccurate or incomplete data can lead to faulty production planning decisions and suboptimal outcomes.

2. Foster cross-functional collaboration

Encourage collaboration and communication among different departments involved in production planning. Facilitate cross-functional teams to share insights, align objectives, and work together towards common production goals. Effective collaboration enhances efficiency and minimizes coordination issues.

3. Enhance demand forecasting and analysis

Utilize the forecasting capabilities of the ERP system to accurately predict customer demand. Analyze historical data, market trends, and customer behavior to refine demand forecasts. Regularly review and adjust forecasts based on changing market conditions to optimize production planning.

4. Optimize resource utilization

Leverage ERP tools to optimize the allocation and utilization of resources such as materials, equipment, and labor. Monitor resource availability, track utilization rates, and identify opportunities to maximize efficiency and minimize waste. Optimal resource utilization enhances productivity and reduces costs.

5. Implement continuous monitoring and reporting

Regularly monitor production performance metrics and generate reports using the ERP system’s reporting capabilities. Analyze production planning key performance indicators (KPIs) to identify bottlenecks, inefficiencies, and areas for improvement. Proactively address issues and implement corrective actions to drive continuous improvement.

6. Establish standardized processes and workflows

Establish standardized processes and workflows within the ERP system to ensure consistency and efficiency in production planning activities. Clearly define roles, responsibilities, and approval workflows to minimize errors and streamline decision-making processes.

7. Regular system maintenance and updates

Perform regular maintenance and updates to keep the ERP system running smoothly. Stay up-to-date with software upgrades and patches provided by the ERP vendor to benefit from new features, bug fixes, and security enhancements. Regular maintenance ensures system stability and reliability.

8. Focus on training and user adoption

Provide comprehensive training to employees on how to effectively use the ERP system for production planning. Encourage user adoption and provide ongoing support to address any questions or concerns. Well-trained and confident users can leverage the full potential of the ERP system, maximizing its benefits.

9. Embrace continuous evaluation and optimization

Continuously evaluate the effectiveness of production planning processes in the ERP system. Regularly review and optimize production schedules, workflows, and system configurations based on feedback, performance data, and changing business requirements. Adapt and improve processes to ensure they align with evolving organizational needs.

10. Collaborate with ERP vendor

Maintain a positive and collaborative relationship with the ERP vendor. Stay informed about updates, enhancements, and best practices related to production planning in the ERP system. Engage with the vendor for support, guidance, and to explore additional functionalities that can further improve production planning processes.

Want to see Katana in action?

Katana’s production planning ERP offers a range of robust features designed to streamline production lines, optimize inventory management, and ensure timely delivery of sales orders, facilitating smooth and efficient operations.

Katana’s production planning ERP software

When it comes to finding a robust and comprehensive solution for production planning within an ERP system, you can’t go wrong with Katana.

Katana’s production planning ERP software offers a range of features designed to streamline production processes, optimize resource allocation, and enhance overall operational efficiency.

With Katana’s intuitive user interface, businesses can easily manage production schedules, track inventory, and plan resources in a single, centralized platform. The software provides real-time visibility into production activities, allowing quick decision-making and proactive management of potential bottlenecks.

With its detailed inventory and production insights, Katana helps businesses align production with customer demand, minimizing stockouts and excess inventory.

One of the key strengths of Katana is its ability to integrate seamlessly with other essential business tools, including:

From shipping to order fulfillment and accounting, Katana offers robust integrations that enable data flow across departments, ensuring cohesive and efficient production planning.

Katana also prioritizes ease of use, making it accessible to businesses of all sizes and industries. The software’s intuitive interface, customizable workflows, and user-friendly design contribute to a smooth implementation process and a shorter learning curve for users.

With its comprehensive features, seamless integrations, user-friendly interface, and focus on efficiency, Katana is a powerful platform for businesses looking to enhance their production planning processes. Get started by booking a demo today.

Henry Kivimaa

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control