Manufacturer serial numbers for product tracking

Manufacturer serial numbers (MSN) are unique identifiers that help track items and enable services such as warranties. Keep reading to learn everything you need to know about MSN numbers.

Henry Kivimaa

If you’ve ever looked at the backside of your TV or navigated to the About menu of your phone, you may have come across a long row of letters and numbers. This is the product’s serial number that enables manufacturers to track items.

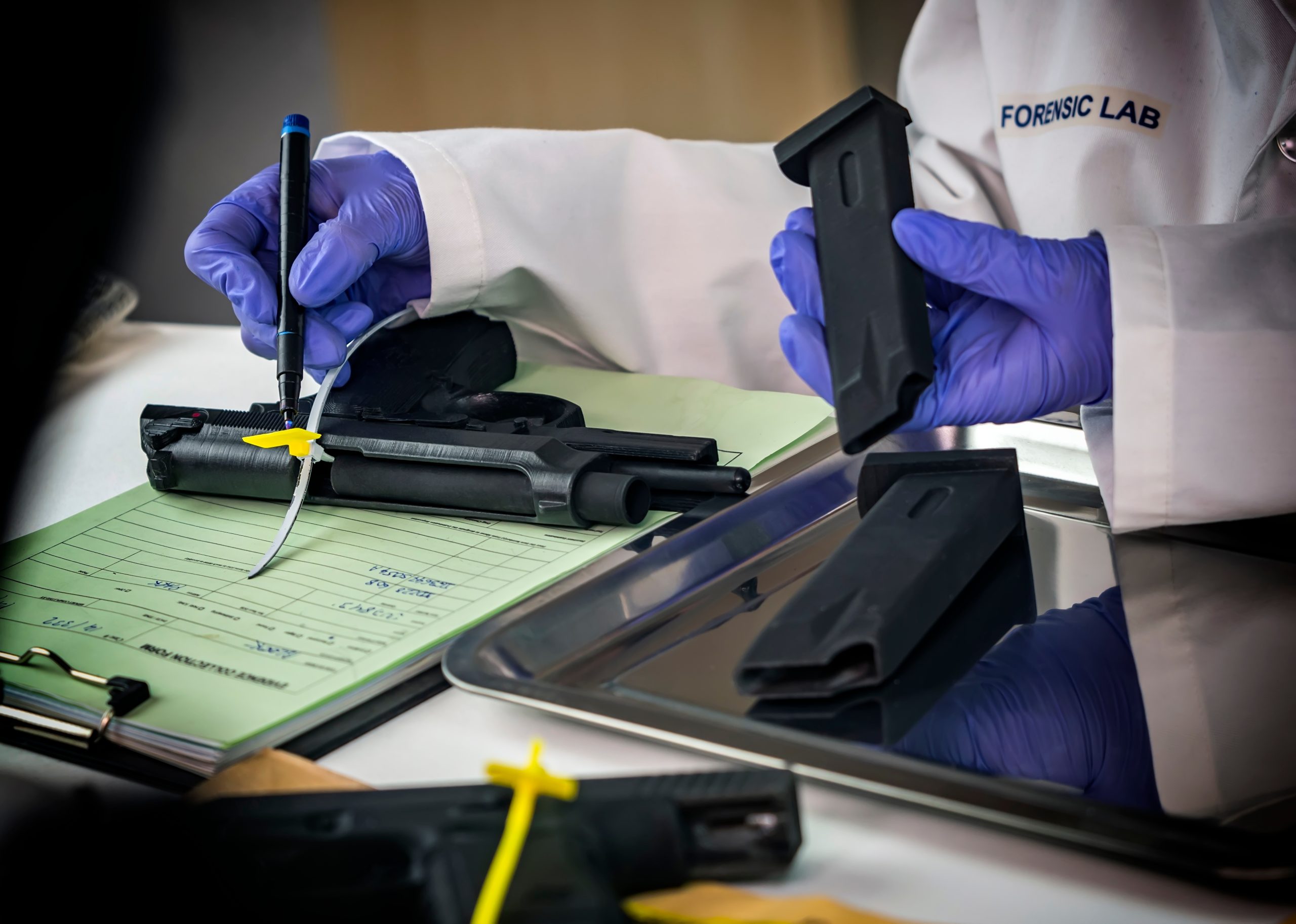

Serial numbers are not required for every manufacturer. For example, you won’t find manufacturer serial numbers on milk cartons or your new cashmere sweater. But they are necessary in the consumer electronics, appliance, and firearms industries.

Let’s dive in and see what are serial numbers used for and how these help with tracking, warranty services, and other crucial functions.

What is a manufacturer serial number?

A manufacturer serial number is a unique code a manufacturer assigns to a specific product during production. This code serves as a distinct identifier for each item, allowing manufacturers to track and manage their products throughout the supply chain and providing a means for consumers to identify and verify the authenticity of their purchases.

Manufacturer serial numbers can take many different forms, depending on the industry and purpose of the product. They may consist of letters, numbers, or a combination of both and may be generated using various algorithms or software tools.

In addition to aiding in product tracking and identification, manufacturer serial numbers can also serve as a useful tool for warranty management, recalls, and product support. By recording the serial number of a product at the time of purchase, consumers can easily access information about the product’s features, warranty status, and any available support resources, making it easier to resolve any issues or concerns that may arise.

What’s the difference between manufacturer serial numbers and lot numbers?

Serial numbers and lot/batch numbers are both unique identifiers used by manufacturers to track and manage their products, but they serve slightly different purposes.

A serial number is a unique code assigned to an individual product, allowing manufacturers to track and identify each item throughout its lifecycle. This code is typically permanent and cannot be changed or duplicated, making it a valuable tool for identifying and verifying the authenticity of a specific product.

In contrast, a lot or batch number is a unique identifier in batch manufacturing assigned to a group of products made together, typically within a specific timeframe or production run. Lot or batch numbers are often used in industries such as pharmaceuticals, food and beverage, and cosmetics, where it is vital to ensure consistency and traceability within a specific group of products.

Download the definitive guide to batch production

Download this free ebook on batch production to learn more about the benefits, workflows, and software you need to get started.

While serial numbers are typically assigned to individual products, lot or batch numbers are used to identify groups of products that share a common set of manufacturing parameters or production history. This makes it easier for manufacturers to trace the source of any quality control issues or defects and take appropriate action to address them.

Overall, both serial numbers and lot/batch numbers are important tools for manufacturers in ensuring product traceability and quality control, but they serve slightly different purposes and are used in different contexts.

Best practices for manufacturer serial number tracking, validation, and traceability

Once manufacturing serial numbers are assigned to products, it’s important for manufacturers to implement best practices for managing these codes throughout the supply chain. Effective serial number management can help ensure product authenticity, prevent fraud, and provide traceability in case of issues or recalls. Let’s go over some best practices for managing manufacturing serial numbers.

Implement a robust tracking system

To manage serial numbers effectively, manufacturers need a system for tracking each code throughout the supply chain. This system should include processes for recording and storing serial numbers, as well as mechanisms for verifying the authenticity of each code.

Validate serial numbers at key touchpoints

To prevent fraudulent activity, manufacturers should implement validation procedures at key touchpoints, such as during shipping, receiving, and inventory management. This can include scanning or checking the serial number against a database to ensure it is valid and has not been duplicated or altered.

Ensure traceability

In case of issues or recalls, it’s important for manufacturers to be able to trace products back to their original source. This requires maintaining accurate records of serial numbers throughout the supply chain, as well as implementing processes for identifying and quarantining affected products.

Regularly audit and update processes

As the manufacturing landscape evolves, it’s important for manufacturers to regularly audit and update their serial number management processes to ensure they remain effective and compliant with industry standards. This can include implementing new technologies or software tools to improve tracking and validation capabilities.

By following these best practices, manufacturers can ensure that their serial number management processes are effective in preventing fraud and ensuring product traceability throughout the supply chain.

Track your serial numbers with Katana

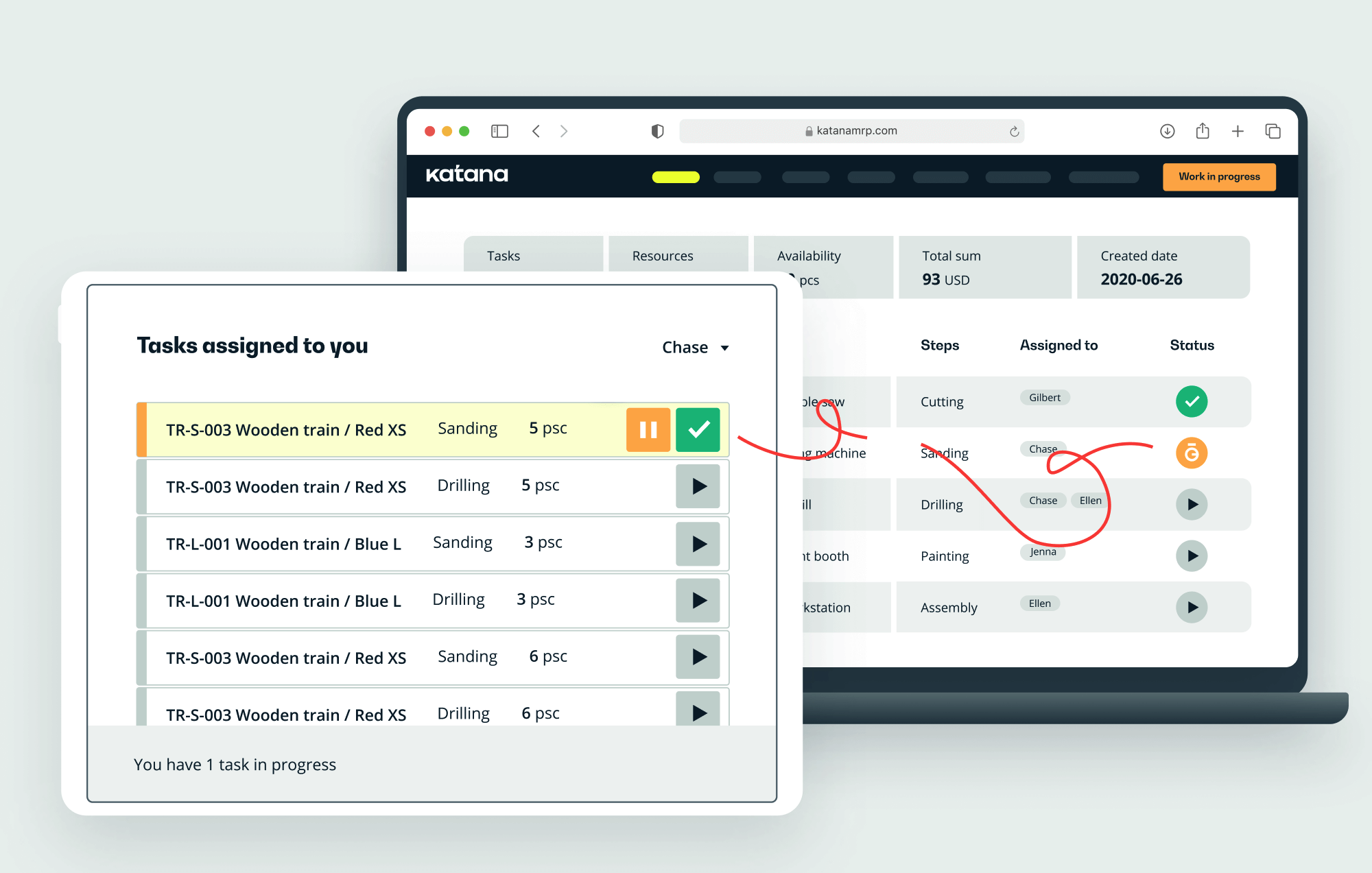

Managing manufacturing serial numbers can be a complex and time-consuming process, but with the right tools, it doesn’t have to be. That’s where Katana comes in.

Katana is a powerful cloud inventory software designed to help small and mid-sized manufacturers manage their production processes more efficiently. One of the key features of Katana is its serial number management capability, which enables manufacturers to track serial numbers throughout the entire production process.

With Katana, manufacturers can assign unique serial numbers to each finished product, allowing for easy tracking and traceability throughout the supply chain. This can help prevent fraud and counterfeiting, as well as provide valuable insights for quality control.

In addition to serial number tracking, Katana offers:

- Real-time inventory tracking

- Production planning and scheduling

- Multilocation support

- Make-to-stock and make-to-order

- Contract manufacturing

- Seamless integrations with the best business tools

Overall, Katana is an ideal solution for manufacturers looking to streamline their serial number management processes and improve overall efficiency. With its powerful inventory management, production control, and integration capabilities, Katana can help manufacturers stay on top of their production processes and ensure the highest level of product quality.

Reach out to our sales team now and request a demo so you can see for yourself why thousands of manufacturers choose Katana.

Henry Kivimaa

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control