Stay efficient with inventory management software

Businesses rely on cloud-based inventory tracking systems for real-time control. Learn how inventory management software provides total control across all your warehouses and supplier locations.

Inventory management software to track stock and optimize resource planning

Discover how a live inventory management system precisely monitors stock, ensuring you have the right raw materials and products on hand to meet customer demand. This effective inventory management software reduces costs and boosts sales, improving your bottom line.

Reduce costs and save time with an inventory tracking system

Tracking your inventory becomes effortless with an inventory management system. Real-time tracking prevents overstocking and stockouts, saving you money and freeing up time to focus on other aspects of your business. Invest in an inventory program and streamline your operations.

Live inventory tracking system like Katana allows you to:

- Get total visibility over finished products and raw materials with live inventory tracking features

- Automate inventory transactions and set reorder points for low stock to prevent shortages

- Track on-hand, committed, and expected stock amounts in real-time

- Manage product variants and materials in one place for end-to-end stock management

- Use barcode scanners to automate inventory processing

Avoid stockouts with multichannel inventory management

Multichannel inventory software is the perfect tool to ensure your most popular items are always available for sale.

Katana’s multichannel inventory software makes it easy to:

- Manage inventory across multiple warehouses and throughout the whole supply chain

- Centralize your inventory data and gain a comprehensive view of stock levels and orders from all your sales channels

- Track availability for required materials for efficient sales order fulfillment

- Get accurate expected production dates to keep sales teams informed

- Integrate your sales platforms and automate your inventory status updates

Make better decisions with the real-time inventory data you need

Real-time data makes it easy to see what’s in stock, what needs to be ordered, and how to optimize your inventory levels.

Katana gives you the real-time inventory data you need to:

- Make accurate purchasing and manufacturing decisions with live data

- Ensure optimal inventory levels at all times

- Prioritize production based on raw material availability

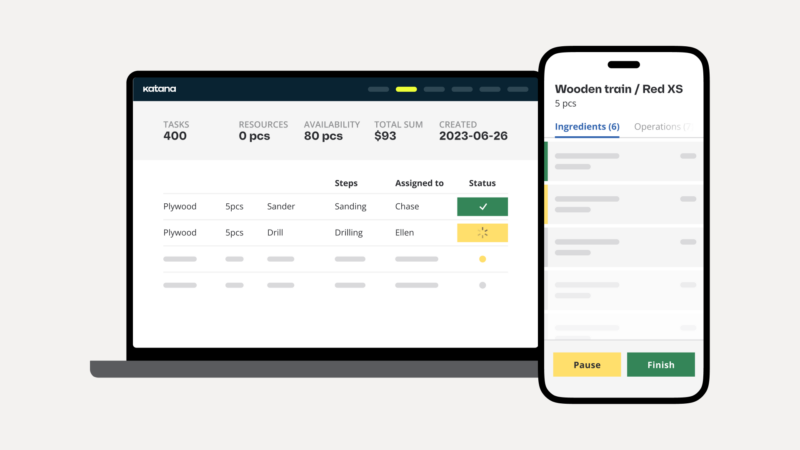

- Get task-level control for effective shop floor management

- Automate manufacturing cost calculations based on your bill of materials and operations

- Keep a close eye on your inventory with warehouse management features

- Establish end-to-end traceability for raw materials and products with batch and serial number tracking

Features

Unlock stock efficiency with inventory management software

With a range of features and functionalities, Katana equips businesses with features to streamline their inventory management, ensure efficient stock allocation, and fulfill customer demands.

Katana add-ons

Extend the functionality of Katana with add-ons and only pay for what you use with a customized setup.

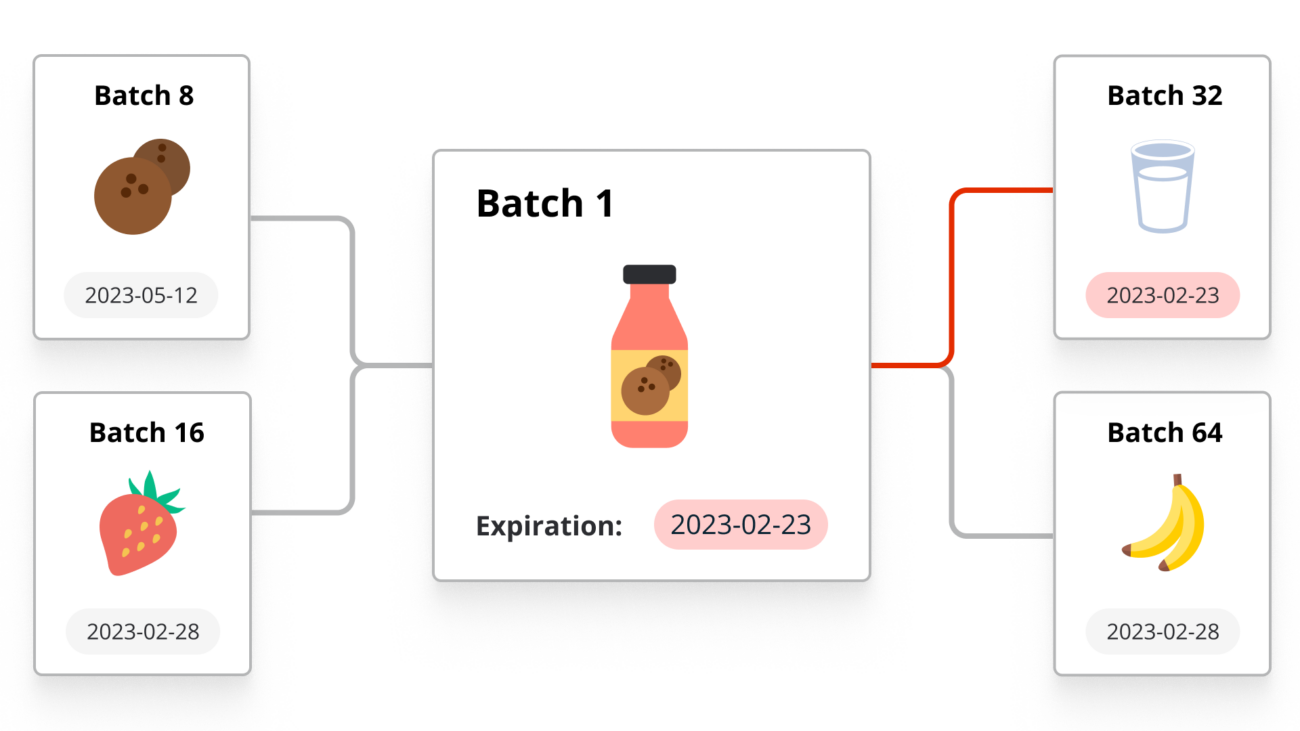

Full traceability

Ensure end-to-end traceability of your products – trace items in batches or by serial numbers

- Serial numbers – track your products via a unique identifier to ensure complete traceability of every product’s history and assist you in warranty device support and recall cases.

- Batch numbers – assign batch or lot numbers to purchased and manufactured items and assign expiration dates to batches to gain further control over the shelf life of your items

$199 / month

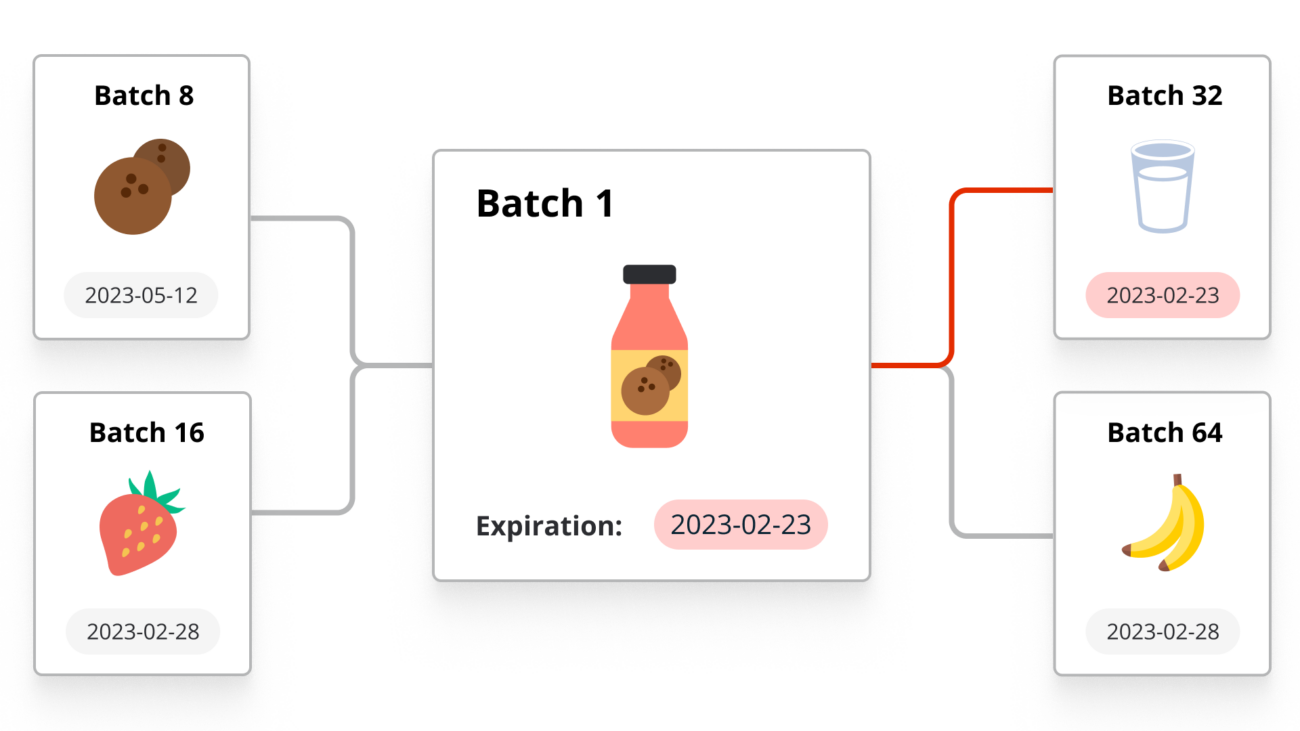

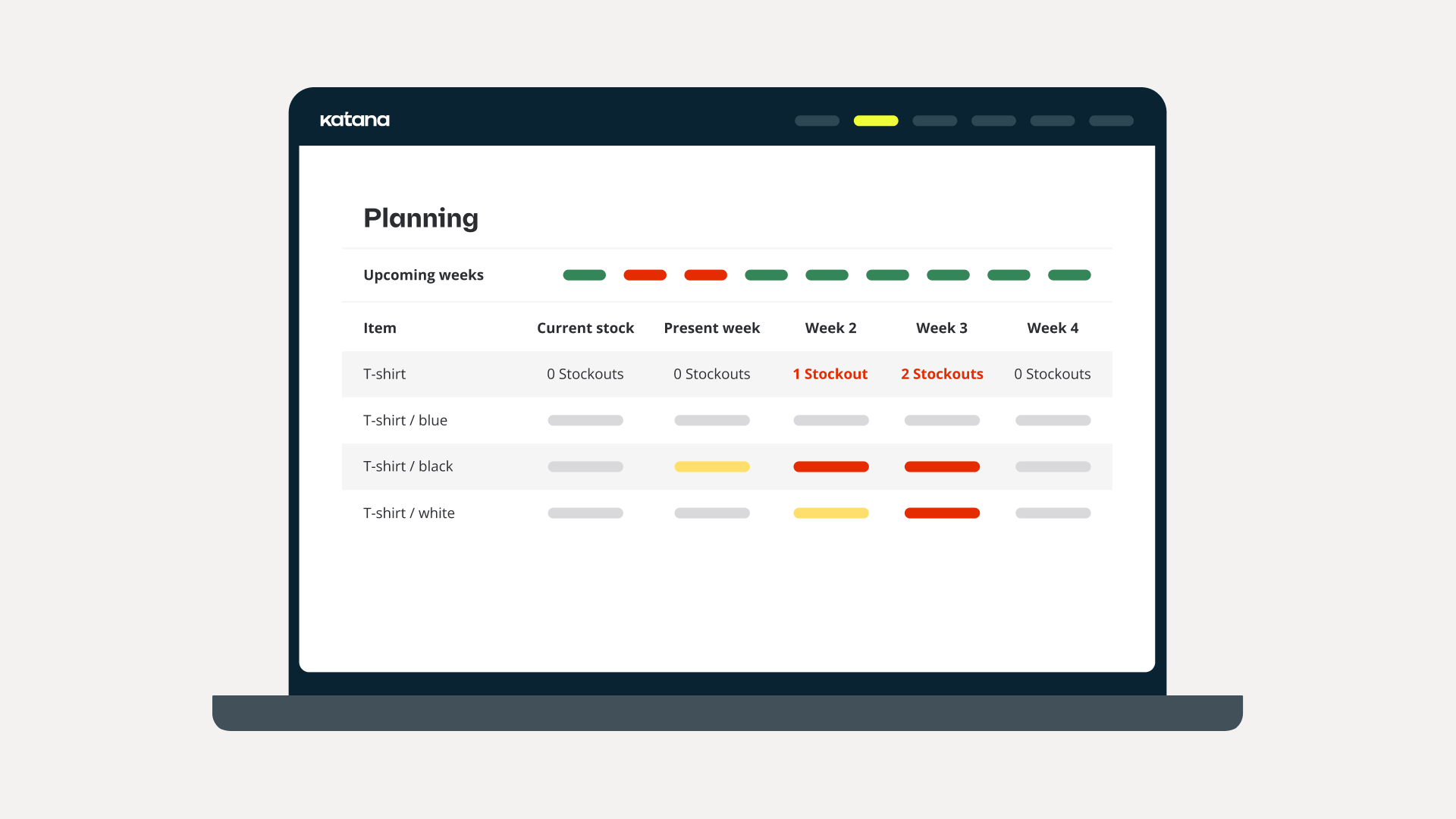

Planning and forecasting

Lift your cashflow and avoid stockouts and overstock with real-time inventory planning and forecasting toolset

- Demand planning and forecasting — Utilize historical data to proactively order and restock items, prevent stockouts, and minimize overstock.

- Replenishment planning — Gain accurate replenishment recommendations, based on real-time demand and sales forecast.

- Flexible inventory control — Set default lead times and minimum order quantities for each product and material.

$199 / month

Advanced manufacturing

Track, schedule and report the progress of your manufacturing operations

- Katana’s Shop Floor app for tracking shop floor operations — Create operators and assign manufacturing tasks to track their progress in real time.

- Manufacturing routings — Set up manufacturing operations in sequence (consecutive or parallel).

- Manufacturing insights — Analyze manufacturing costs, resource and materials usage.

From $199* / month

*Pricing depends on your plan

Warehouse management

Gain stock visibility inside warehouses and simplify daily operator tasks

- Planning sales order fulfillment — Use a mobile app to optimize your order fulfillment process by assigning tasks to warehouse operators and getting live updates from the warehouse.

- Picking and packing sales orders with a mobile device — Pick and pack on the go with the Warehouse App.

- Barcode scanning — Unlock speed and accuracy in picking stock by scanning products and material barcodes.

- Bin locations — Assign default storage bins to items and organize your warehouses to make finding item locations or destinations effortless.

$199 / month

Integrate with the best ecommerce, accounting, reporting, and CRM apps out there

All your business tools — connected

Optimize your workflow with native and third-party integrations, automating data transfer between systems and reducing errors. Or build your own custom integrations using the open API for seamless data flow with other applications. Check out the API documentation for more details.

Katana provides us with all the features for manufacturing order management and can track inventory usage and incorporate our sales order tracking into Katana.”

Mikhail Moore

Chief Executive Office (CEO) at Vitacore Industries

It’s great to be able to see where inventory faults happen and being able to fulfill orders and where the turnaround happens.”

Alaina Oehrlein

Production Lead at Essence One

Katana accurately keeps stock of assemblies and ingredients so that I can plan production and get instant feedback on whether we enough resources in stock.”

Kelly Costello

Chief Executive Officer (CEO) at Puppy Cake

We also wanted an accurate inventory system for batch planning, warehousing, and sales. Katana fulfills all our needs in a simple, easy way, unlike other inventory solutions.”

Irah Vet

Founder and Production Manager at Hornby Organic

Inventory management software FAQ

Inventory management software is a tool designed to help businesses track, manage, and optimize their inventory levels, orders, sales, and deliveries. It automates many inventory-related tasks and provides real-time data to improve efficiency and reduce costs.

The best inventory management program depends on your specific needs. Popular options include Katana Cloud inventory platform, Ordoro, TradeGecko, and Fishbowl for small to medium businesses, and NetSuite or SAP for larger enterprises.

If you wish to learn more about these, take a look at the article about the list of the 7 best inventory management software.

The perfect inventory management software depends on what your specific business requirements are. However, there are some features that are beneficial for everyone, regardless of the size and industry of the company.

Here are a few features that you should look out for in an inventory management solution.

- Real-time tracking — Inventory software should offer live inventory tracking, allowing you to monitor stock levels, sales, and order fulfillment as they happen.

- Multilocation support — Inventory tracking software should be capable of handling inventory across multiple locations, ensuring efficient distribution and management.

- Barcode and labeling — Support for barcode and labeling systems simplifies tracking and improves accuracy in inventory management.

- Integrations — Integrating with other business software and sales channels is vital to maintain accurate data across the organization.

- Reporting and analytics — Comprehensive reporting and analytics tools help you make informed decisions, identify trends, and optimize your stock levels.

- Demand forecasting — The software should offer demand forecasting capabilities to help prevent stockouts and overstocking.

- User-friendly interface — An intuitive interface makes it accessible to businesses of all sizes, reducing the learning curve and ensuring efficiency.

- Customization — Flexibility to customize the software to meet the unique needs of your business is essential to fulfill your specific needs.

- Scalability — As your business grows, the software should be able to scale with you, accommodating more products and locations.

- Lot and batch tracking — For businesses dealing with products that have lot or batch numbers, the ability to track these is crucial for quality control and recalls.

- Multichannel support — Multichannel businesses should ensure the software can manage inventory effectively across various sales channels, including e-commerce, retail, and wholesale.

- Supplier management — Features to manage supplier relationships, including lead time tracking, can aid in efficient inventory management.

Excel is not a dedicated inventory management software, but it can be used to create basic inventory management systems using spreadsheets. However, it lacks the advanced features of specialized inventory management tools.

Yes, QuickBooks offers basic stock management features, including tracking inventory levels and costs and generating related reports. For more advanced inventory management needs, integrating QuickBooks with specialized software, like Katana may be necessary.

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control