Cost of poor quality in manufacturing: How to cut out the losses

Cost of poor quality (COPQ) is an essential accounting formula for calculating losses from poor quality products and services.

Team Katana

The manufacturing sector has companies that deal with food and beverages, oil and gas, medical devices, and many more.

Ultimately, the primary goal of every business is to make money. Nowadays, making reasonable returns involves adopting advanced manufacturing approaches that prevent poor quality products from tainting the overall customer experience. However, good quality, as well as poor quality, comes at a cost.

Every average manufacturing company has a cost of poor quality at about 20% of the total sales. For a company generating $10 million in revenue, nearly $2 million is dedicated to costs associated with production and costs deployed to address one quality issue. That is a lot of money and time spent on addressing poor quality.

Understanding the cost of quality (COQ) and how to minimize poor quality would be instrumental in boosting many companies’ reputations. While it is greatly beneficial to have a speedy and seamless manufacturing process, one cannot ignore the impact of the cost of poor quality in manufacturing.

With all that said, what are the cost of poor quality in manufacturing?

What is the cost of poor quality?

Cost of poor quality (COPQ) is the quality-related cost that is associated with providing products or services that are of poor-quality products to target clients or customers. These costs could be direct or indirect, such as repair, labor, warranty failure, and returns.

The 4 costs of quality

In evaluating the cost of quality (COQ), there are four quality-related activities that incur costs.

1. Prevention costs

These costs are incurred to prevent the occurrence of problems. This includes:

- Staff training

- Certification

- Machine maintenance

- Quality assurance

- Quality planning

- Competent management solutions.

2. Appraisal costs

These are the costs incurred to ensure the product conforms to the required quality. Examples include things such as:

- Supplier rating

- Quality audits

- Verification

3. Internal failure costs

These are costs that are incurred to fix problems that are noticed before delivery, such as:

- Waste

- Rectification

- Scrap

- Failure Analysis

4. External failure costs

These are costs incurred to fix defects or problems discovered by the end users after the product has been delivered, like:

- Servicing and repair

- Warranty claims

- Returns

- Complaints

What is the cause of the cost of poor quality?

Looking into the cost of poor quality, managers and manufacturers can identify the causes of poor quality in both the production line and supply chain.

A breakdown of the values can pinpoint the areas where problems arise. The cost of poor quality usually comes from the following areas:

- Improper handling of production materials

- Wrong content input on both product and product package

- Improper assembly of parts during production

- Defective parts being used in the manufacturing process

- Misidentified parts being mislabeled and used in production

Like in any field, avoidance of errors before, during, and after the production process helps to reduce the cost of poor quality.

Why is understanding the cost of poor quality (COPQ) important?

COPQ is crucial to manufacturers who want to stay on top of the production process and product quality. It has proved useful over the years and has the following benefits:

- COPQ explains the effect of quality on the profitability of the company

- It helps management understand what goes on within the production and helps them identify issues

- It helps to push and prioritize improvement actions

- It leads to resource optimization and identification of waste in the system

- It promotes healthy and continuous improvement culture

With an increase in advanced manufacturing, companies are using artificial intelligence (AI) and augmented reality (AR). Even with these developments, COPQ remains very important. This is why there are many ERP packages and software that help in calculating COPQ.

They can calculate and publish results while utilizing the COPQ to use business solutions effectively.

How do you calculate the cost of poor quality in manufacturing?

The cost of poor-quality calculation formula is derived from the definition of COPQ.

A manufacturing company’s COPQ is the total sum of all associated costs incurred as a result of failure — it could be external or internal. Hence, the poor-quality formula is:

Poor Quality = Internal Failure Costs + External Failure Costs

Thus, in Calculating COPQ, you need to determine the time period of evaluation to keep your data streamlined.

Then sum up the total variation/waste and multiply your total by the time spent resolving the issue. The result should be the cost of poor quality incurred by your manufacturing company:

COPQ = (Waste + Defects ) * Time Spent Fixing

An example of the cost of poor quality (COPQ)

If you’re running a project and you need to determine the COPQ, you’ll need to define what your company identifies as a defect.

You will also measure how many defects you produce along your production process.

For example, imagine your company is producing electric kettles. For every 1 million kettles produced, about 4% come out damaged — based on your definition of damage. That makes 40,000 kettles. If these kettles are not repairable, producing one unit costs about $50.

This means it cost your company 40,000 * $50 = $2 million.

The quality cost is $5 per unit to determine if a kettle is defective. With 40,000 units, that means another $200,000 is spent in total.

Then the total COPQ is:

COPQ = $2 million + $200k = $2.2 million

This is the total cost of poor quality on your company.

Regardless of the markup, that is a huge chunk of the capital and possible revenue that cannot be recovered. This could have been avoided if the quality had been followed from the beginning of the production process.

6 disadvantages of cost of poor quality (COPQ)

What happens when the manufacturing approach has little to no quality assurance?

Discovering quality issues early helps reduce the cost of poor quality and avoid further complications. The following are disadvantages of COPQ.

1. Financial loss

When a large part of the proposed revenue goes into inspection, investigation, and repair of damaged poor, quality products, the manufacturing company can face a financial loss.

2. Schedule delay

When the manufacturing process slows down, it has a ripple effect because the supply chain depends on the producers, and there is a delay in the supply schedule.

3. Wasting human resources

There will be a need for more checks and controls on the product quality. This strains the quality managers and the management system, leading to a waste of human resources and capacity planning issues.

4. More money spent

Once you know where your business is failing, you will need to spend more money on the problem to reproduce or fix the products.

5. Puts the company’s reputation on the line

The health and safety of your clients is a priority. When a company product jeopardizes any of those two things due to poor quality, it affects its reputation.

6. Competitors steal your customers

While sorting out the quality-related costs and redeeming your brand name, your competitor could steal your customers.

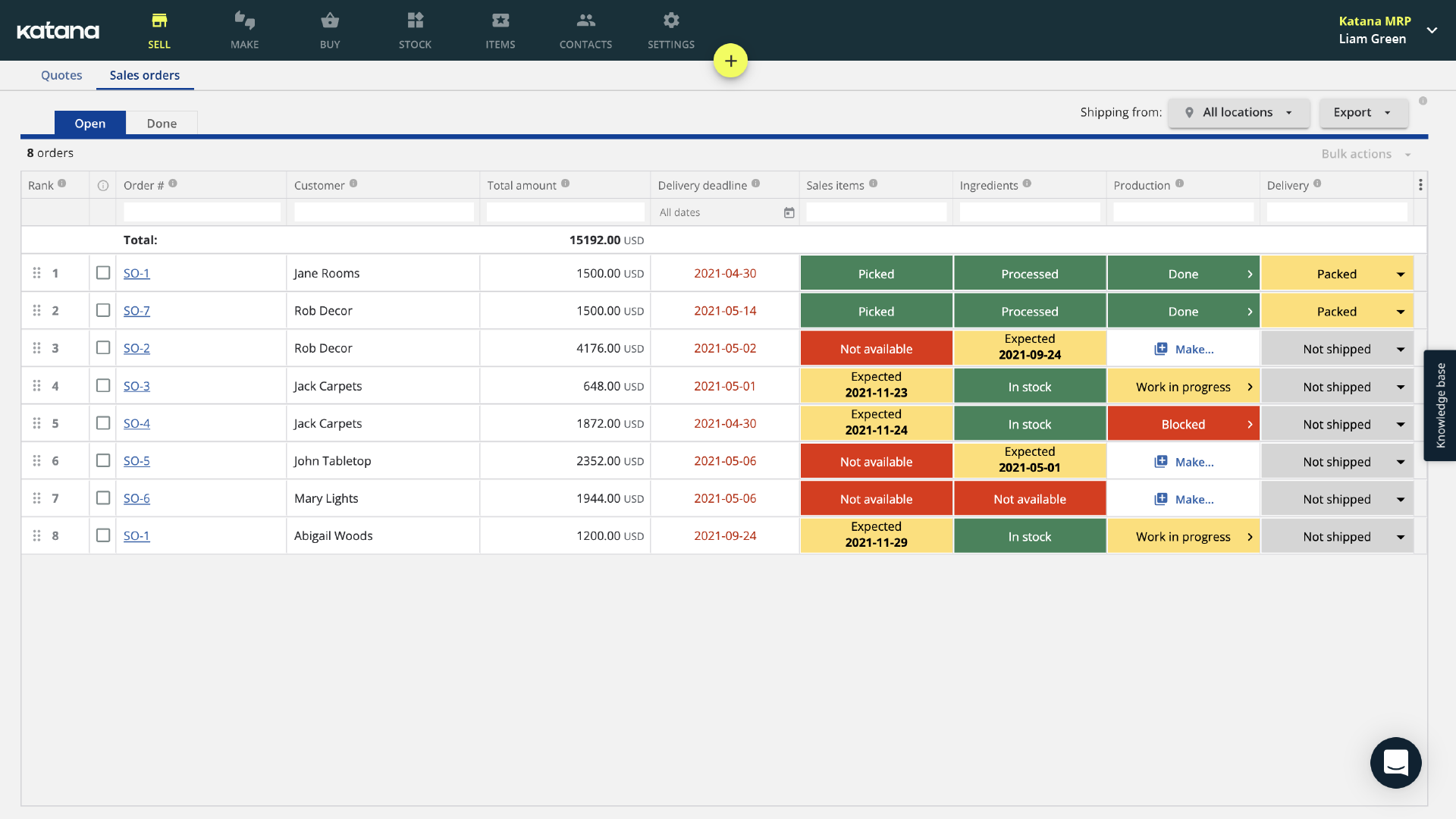

Want to see Katana in action?

Book a demo or get started with Free Plan to get all your questions answered regarding Katana’s features, integrations, pricing, and more.

Using enterprise resource planning (ERP) systems for COPQ

Enterprise resource planning systems provide the necessary features for lowering the cost of poor quality.

The featured resources of ERP help monitor the manufacturing environment, which has many benefits. Just to name a few:

- Reduction in the occurrence of errors

- Improving the quality standards of all products

- Visibility of all aspects of the manufacturing process

- Real-time observation and documentation of the production line performance

- Waste elimination and implementation of lean practices in production

COPQ — wave goodbye to poor-quality products

The cost of poor quality in manufacturing is something that many prominent companies are striving to reduce daily.

It’s in their own interest to identify the issues early and reduce the costs. Having a low COPQ shows your business is healthy and sustainable. Every company should invest in calculating their COPQ and effectively reducing it with quality management solutions.

Do not leave COPQ unaddressed, as it can be detrimental to your company’s bottom line and deter customer loyalty.

Get started by booking a demo with Katana, and get a head start on your competitors.

Team Katana

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control