The ultimate guide to circular economy and closed-loop manufacturing

Ioana Neamt

Our world is getting hotter, partly due to product waste. As products decompose in landfills, they release harmful gasses like CO2 and nitrogen into the atmosphere. A circular economy strives to end harm to our planet by recycling existing materials and keeping them in circulation for as long as possible.

Implementing a circular economy into your business’ manufacturing practices not only saves our environment — it saves money, too.

In this ultimate guide, we cover everything you need to know about circular economies and closed-loop manufacturing. This will help you make your business more sustainable and protect the future of our planet.

What is a circular economy?

A circular economy is a type of economic system that aims to eliminate unnecessary waste and continually use resources.

In a traditional linear economy¹, manufacturing revolves around the “take, make, dispose” model. In other words, people buy products, use them, and then throw them away.

Circular economies aim to get rid of this harmful system and instead design products that minimize overall waste to avoid further pollution. To do this, products are repaired, reused, refurbished, and recycled to keep them in circulation for as long as possible before being placed in landfills.

If enough companies invest in a circular economy, the world will begin to rebuild itself by regenerating its natural systems. Valuable nutrients will return to the soil, improving Earth’s health one step at a time.

The goals of the circular economy are to:

- Eliminate waste and pollution — Redesign the traditional linear economy to prevent waste and pollution from happening in the first place

- Keep materials in use — Extend the lifespan of products by reusing and refurbishing existing materials already in circulation

- Regenerate natural systems — To protect ecosystems, circular economies aim to restore natural systems by returning nutrients to the soil and improving overall biodiversity

Key features of a circular economy

Now, let’s take a look at the key features of a circular economy designed to make manufacturing more sustainable in the long term.

1. Sustainable product design

In a circular economy, durability and repairability are priorities when designing products. They also need to be easily disassembled to refurbish and recycle products. Typically, materials will be renewable and recyclable for a lower environmental impact.

2. Using resources more efficiently

Currently, the industrial sector uses 54% of the world’s energy². Circular economies aim to counteract this by using energy-efficient technology while creating products. Water recycling is also encouraged during the industrial process.

3. Reducing waste

One key feature of a circular economy is the idea of zero waste. This means all products need to be reusable and recyclable so they don’t end up in landfills.

4. Extending the life of products

Rather than throwing away products at the end of their lifecycle, circle economies promote refurbishing them to make them as good as new. Businesses like ThreadUp also have second-hand markets where products are bought. The second-hand market in the US is expected to reach $73 billion by 2028³.

5. Using renewable energy

Along with cutting down on energy usage during the manufacturing process, circular economies encourage manufacturers to use clean and renewable energy sources to reduce their carbon footprint.

What are the benefits for your business?

As well as reducing your carbon footprint and keeping the planet healthy, there are plenty of other benefits from adopting a circular economy for your business. Below, you’ll find some of the most impactful ones from a business perspective.

Cost savings

- When businesses reuse and recycle materials, they can greatly reduce the amount spent on raw materials.

- Reducing waste production can lower the cost of waste management and disposal.

- Using energy-efficient techniques will mean you spend less on your energy bills.

New revenue streams

- Selling refurbished, remanufactured, or recycled items can help businesses tap into new sources of income. People not willing to pay full price for a new product, may consider a refurbished item for a significant discount.

- Providing products through services like leasing or subscriptions creates reliable and ongoing revenue streams.

Market differentiation

- Creating groundbreaking products and services based on circular principles can set a company apart from competitors.

- Embracing sustainable methods can draw in eco-conscious customers and strengthen brand allegiance. This is particularly beneficial given that 78% of consumers⁴ consider sustainability important.

Job creation

- Circular economies have the potential to create job opportunities in emerging fields like recycling and remanufacturing.

- By promoting local manufacturing and recycling initiatives, your business will help to grow local economies and boost job opportunities.

What are the challenges of a circular economy?

Despite all the benefits of circular economies, it’s still a new concept. Because of this, implementing an effective circular economy into your business’ manufacturing processes can be tricky. Here are some challenges you might face.

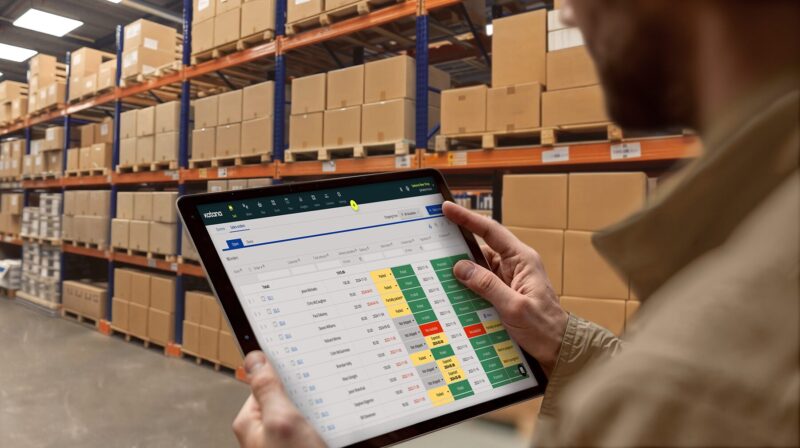

Dealing with complex supply chains

Implementing circular practices without technology can be difficult. You need to collaborate with suppliers, manufacturers, and retailers, which is challenging to coordinate. Luckily, Katana offers supply chain software that makes upholding a circular economy easier than ever.

High upfront investment

You may be hesitant to invest in circular economy practices at first because the short-term costs can be higher than sticking to what you know, aka a linear economy. However, long-term economic gain is normally greater than the short-term cost.

Technical barriers

Adopting new and complex technologies for waste recycling and product design is essential when implementing a circular economy. Having to do this can be costly and time-consuming.

What is closed-loop manufacturing?

Closed-loop manufacturing is a key part of a circular economy. It refers to a new production process in which materials are continuously recycled and put back into manufacturing rather than thrown away.

Rather than a linear manufacturing model of “take-make-dispose,” this production process “closes the loop,” meaning materials are continuously recycled and not thrown away after one use.

How does it work?

Closed-loop manufacturing works by creating a cycle where all materials are reused and recycled and then eventually reintegrated into production. Here are the typical steps in the closed-loop manufacturing process.

1. Collection and sorting

Used products are collected at the end of their life, inspected, and then sorted based on the materials they were made from and their condition.

2. Disassembly and recovery

Products and materials that can be refurbished are disassembled into individual parts and cleaned. All materials that can’t be salvaged are then separated for recycling.

3. The 3 Rs: refurbishment, remanufacturing, or recycling

All second-hand products are either refurbished, broken down and remanufactured, or recycled.

4. Integration into production

New products made from recycled materials are created by blending or treating old materials to ensure they’re of good quality. All new products then go through quality control so they meet the required standards.

5. Sales

The finished products are sold to consumers.

3 closed-loop manufacturing examples

Let’s take a look at three examples of closed-loop manufacturing in action from businesses Patagonia, Nike, and Dell.

1. Patagonia

Outdoor apparel company Patagonia uses a closed-loop manufacturing practice as part of its sustainability commitment. The Worn Wear Program allows customers to return their clothes for repair or recycling.

2. Nike

Nike, the leading footwear company, practices closed-loop manufacturing through its Grind Program. Scraps from manufacturing are recycled into materials for new products. Nike also uses sustainable products like polyester and rubber, which can be easily recycled.

3. Dell

Dell Technologies is a global tech company that currently uses closed-loop manufacturing practices in computer production. Plastic from their recycled electronics is then used to manufacture new computer parts. Its Asset Recovery Service allows customers to return their end-of-life computers so they can be recycled.

Working towards a circular business model with Katana

Starting on the path to a circular business approach is only possible with the right tools and strategies. Katana can assist you during every step of your journey to sustainable manufacturing.

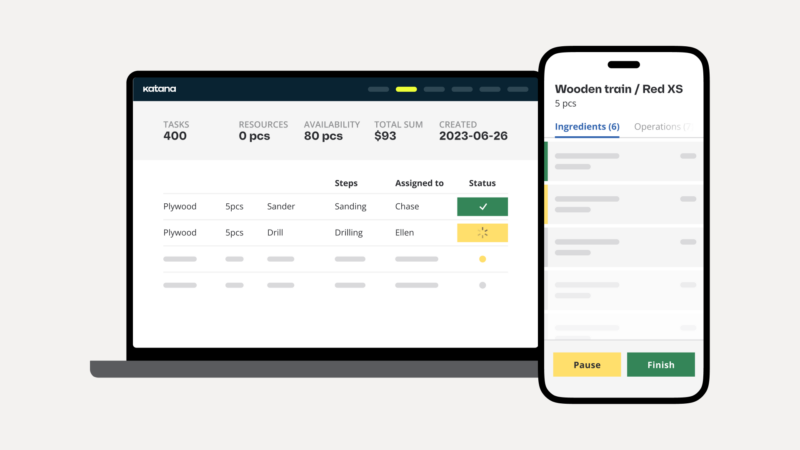

With Katana by your side, you’ll be able to better manage your inventory, purchases, sales orders, planning, and forecasting within a single platform. Our powerful software allows you to optimize your production line and view your inventory levels in real time.

Using Katana will help you not only boost productivity but also reduce waste generation and maximize how you use your resources.

Whether you’re involved in sales activities, manufacturing operations (or both), Katana offers the technology necessary to advance your circular business model.

Join us in transforming your business operations and contributing towards a more sustainable future with Katana. Get a demo now to see it in action!

FAQs

A circular economy is an economic system that eliminates waste and continually uses resources. It helps reduce environmental pollution and protects natural resources which are depleting rapidly.

A circular economy promotes sustainability and reduces the harmful effects of traditional linear economies by recycling materials that already exist and keeping them in circulation for as long as possible.

Closed-loop manufacturing has a crucial role in a circular economy. Rather than disposing of materials after a single use, they are recycled and reintegrated into the production process. This not only reduces waste but also conserves your valuable resources.

Companies like Patagonia, Nike, and Dell showcase the success of closed-loop manufacturing in improving sustainability in production.

Shifting to a circular economy may pose some challenges. However, there are strategies available to help your business tackle them.

Building strong partnerships with suppliers, manufacturers, and retailers is crucial for navigating intricate supply chains. Using technology like Katana’s supply chain software can also streamline operations and simplify the process of switching to a circular economy.

By embracing new technologies for recycling waste and designing products innovatively, your business can stay ahead of the game and establish itself as a sustainability frontrunner.

Sources

¹What is the linear economy, Ellen MacArthur Foundation

²International Energy Outlook 2016, U.S. Energy Information Administration (2016)

³ThredUp: US secondhand market to hit $73B by 2028, Industry Dive (2024)

⁴52 Huge Environmentally Conscious Consumer Statistics, TheRoundup (2024)

Ioana Neamt

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control