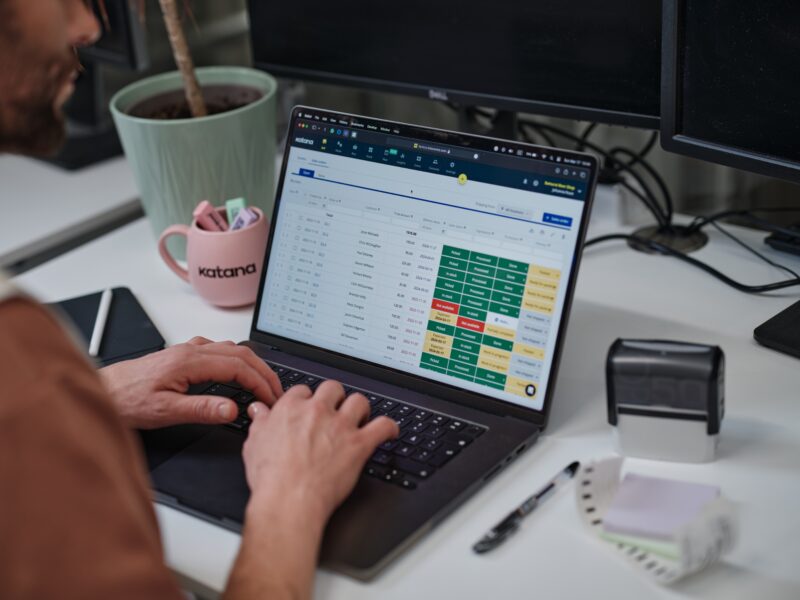

Get the real-time data you need with manufacturing software

Katana equips you with live insights about your production processes, inventory, and sales. Gain easy access to all the information you need, allowing you to make informed decisions and elevate your manufacturing business to new heights.

Connect all the moving parts of your business with manufacturing software

Managing teams, products, and data in real time is a struggle for any business, and manufacturers are no exception. Cloud manufacturing software gives you the visibility you need to keep your products and teams moving.

Cloud manufacturing software, no matter where you are

Cloud manufacturing software doesn’t require expensive hardware or time-consuming installations. All you need is an internet connection and a browser. This allows you to access real-time data on the fly, no matter where you are. Cloud manufacturing software ensures that your team stays connected and informed about their work and schedules, whether they’re at the office or on the move.

Cloud-based software for manufacturing also enables you to seamlessly integrate with other cloud-based solutions, enabling easy data transfers between the services you use.

Katana’s cloud manufacturing software allows you to:

- Monitor your inventory levels and production processes in real time from anywhere

- Integrate with the best business tools for a unified experience

- Effortlessly track your sales performance and other business-related metrics

- Create multilevel BOMs with subassemblies for accurate costing

- Make precise pricing decisions based on your product margins

Key functions of manufacturing software

Manufacturing ERP software centralizes all your business processes into a unified system. It also integrates seamlessly with a wide range of business platforms, enabling you to expand the features while keeping all your systems synchronized.

Planning and scheduling

Intuitive production planning and scheduling to ensure you meet customer demand, minimize costs, and maintain smooth workflow.

Manufacturing execution system (MES)

Sync inventory and sales across all channels with one unified platform and prioritize task lists for production line operators to ensure efficiency.

Manufacturing resource planning (MRP)

Optimize your resource allocation, track your stock movements, and manage your inventory from raw materials to finished goods.

Shop floor control

Assign tasks to your team, track materials and time spent, and access real-time shop floor insights for total shop floor control.

Manufacturing accounting

Integrate with the best accounting software like QuickBooks Online and Xero to keep your accounting data in sync.

Benefits of manufacturing software

Manufacturing software allows you to effortlessly manage raw materials, work-in-progress, and finished goods, even with multiple product variants. Adapt your production plans on the fly to meet demand, optimize resource utilization, and define bill of materials for maximum production scheduling effectiveness.

Whether you choose make-to-order or make-to-stock workflows, manufacturing software ensures you meet customer demand while maintaining optimal inventory levels.

Furthermore, Katana’s Shop Floor App lets you assign tasks to operators, monitor real-time progress, and efficiently manage resources. Say goodbye to order management headaches as Katana consolidates sales and purchase orders from all channels into a single view, providing real-time product availability tracking.

Manufacturing ERP software like Katana makes it possible to:

- Make accurate manufacturing and purchasing decisions with live data

- Ensure optimal inventory levels at all times

- Prioritize production based on raw material availability

- Get task-level control for effective shop floor management

- Automate manufacturing cost calculations based on your bill of materials and operations

Get software that works with you

Test it yourself for free or book a demo with our team. Explore core features with your own data, no credit card required — or get a tailored walkthrough to see how Katana fits your workflows.

Integrate your tools and streamline your workflows

Keep your business connected with Katana at the center of your operations. Our native integrations and an open API ensure real-time data flow across all platforms. Build a tech stack that’s tailored to your needs, simplify processes, and scale with ease.

We chose Katana because it presents our manufacturing business information in the easiest possible way.”

Miguel SalazarManager at IDC Componentes

We needed help with Shopify inventory management for raw materials, and Katana exceeded our expectations.”

Pablo Baque

Walk With Me CEO

We chose Katana because it seemed to be the most user-friendly software we tried – it is very easy to use and the customer service is great!”

Candice MurnoFounder and Designer at Buttercream Clothing

Katana accurately keeps stock of assemblies and ingredients so that I can plan production and get instant feedback on whether we enough resources in stock.”

Kelly CostelloChief Executive Officer (CEO) at Puppy Cake

Manufacturing ERP software FAQs

ERP or enterprise resource planning software are applications developed for manufacturing purposes. Manufacturing companies use it to manage manufacturing processes from the procurement of materials up to the shipment of goods. Manufacturing ERP ensures that manufacturing companies can transform raw materials into finished goods at a minimal cost while maintaining quality control.

The manufacturing ERP software industry began in the 1960s when manufacturers began recording workflow processes on mainframe computers. With the ever-increasing demand for computerization, manufacturing ERP systems have become an integral part of business operations in any manufacturing organization. Key functionalities included in manufacturing ERP systems are sales and distribution, warehouse and inventory management, production planning and controlling, factory maintenance and manufacturing, and sourcing and procurement.

Material requirements planning (MRP I):

- Focus — Primarily focuses on managing and planning for the materials required in production.

- Scope — Limited to material inventory control and production scheduling.

- Functionality — Helps in determining what materials are needed, when they are needed, and how many are needed to meet production demands.

- Benefits — Reduces inventory costs, prevents shortages, and optimizes material purchasing.

Manufacturing resource planning (MRP II):

- Focus — Expands beyond materials to include other manufacturing resources.

- Scope — Encompasses material planning, capacity planning, and scheduling of various manufacturing resources.

- Functionality — Integrates material planning with other aspects of production, such as labor and machine capacity.

- Benefits — Enhances production efficiency, resource allocation, and overall coordination.

Enterprise resource planning (ERP):

- Focus — Provides a comprehensive view of all business processes beyond manufacturing.

- Scope — Covers not only manufacturing but also finance, HR, sales, and other aspects of the business.

- Functionality — Integrates and streamlines all core business functions into a single software system.

- Benefits — Offers end-to-end visibility and control across the entire organization, improving overall efficiency, decision-making, and collaboration.

In summary, MRP I focuses on material planning, MRP II extends to broader manufacturing resources, and ERP encompasses all aspects of an organization, making it the most comprehensive solution. The choice between them depends on the specific needs and scale of your business operations.

To learn more about the differences, you can read this comprehensive guide about MRP systems.

Manufacturing ERP software is an industry-specific software that manufacturing companies need to manage manufacturing processes and manufacturing resources such as machines, people, and materials. Manufacturing ERPs can be used in every step of the manufacturing process, from manufacturing planning (MRP) and manufacturing execution (MES) to manufacturing financials (AP/AR, CP, SCM).

ERP systems are focused on the horizontal business functions of a company, while manufacturing ERPs provide vertical capabilities by adding more specialized features like machine control and production tracking modules. For example, depending on the level of automation of its equipment, a manufacturing company may require automation feeder management capability from its supplier, which is not likely to be available from an industry-generic system.

ERP software allows manufacturing companies to streamline their internal operations and become more efficient and productive. If you want your manufacturing organization to grow, using a manufacturing ERP system will help you achieve that goal. While top management is making strategic decisions about the company’s future, middle managers are responsible for executing business processes on the shop floor that make achieving them possible.

Middle managers need live information at their fingertips to make informed decisions quickly and confidently as they monitor production activities within their department or work unit. This ensures consistency in complying with policies, rules, and regulations. It also helps identify areas of improvement, such as bottlenecks that may be slowing manufacturing down due to a lack of materials.

ERP manufacturing software enhances manufacturing productivity, increases manufacturing flexibility, and improves manufacturing efficiency. It allows companies to benefit from economies of scale by reducing costs by integrating the entire business process under one solution. It also makes information sharing easier among employees, eliminating duplication of efforts.

And finally, it provides an enterprise-wide view of operations that enables companies to make intelligent decisions that increase their productivity and profitability. Manufacturing ERP solutions can be configured based on your organization’s needs and integrated with other software applications. Therefore, you get a cohesive business system where all business processes work seamlessly together for maximum results.

Manufacturing ERP software brings manufacturing companies to the next level, allowing them to compete more effectively against larger manufacturing organizations. Using a manufacturing ERP system, you can increase your manufacturing flexibility by making changes quickly and easily without disrupting manufacturing processes. Better decision-making is made possible with manufacturing ERP as it provides real-time information about manufacturing operations, which means faster reaction time to ever-changing business conditions.

Lastly, manufacturing ERP systems help manufacturers achieve a high return on investment through centralized data storage and ease of integration with other business applications. Until recently, manufacturing ERPs were only accessible to larger manufacturers. Legacy software like Oracle ERP, Oracle ERP Cloud, and SAP S4HANA is no longer the only option, with more competitors available to cater to more modest budgets.

ERP systems typically come with several modules, including a manufacturing execution system module, manufacturing resource planning module, shop floor control module, enterprise manufacturing intelligence module, and master production scheduling module. Manufacturing ERP solutions also have various industry-specific modules that streamline processes relevant to our line of business, making it more efficient.

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control