Order processing management explained

What is order processing in supply chain management and how can you make it as efficient as possible? Read on to find out.

Henry Kivimaa

Efficient order processing management is crucial for manufacturers to meet customer demands, optimize inventory utilization, and ensure timely order fulfillment. This blog post explores what is order processing in supply chain management, the steps involved, and how you can manage your orders as effectively as possible.

What is order processing management?

Order processing management refers to the set of activities and processes involved in managing customer orders from the initial placement to the final fulfillment and delivery. It encompasses all the steps required to ensure that customer orders are accurately received, processed, tracked, and fulfilled in a timely manner.

These steps include order receipt, order validation, inventory allocation, picking and packing, shipping, and order tracking.

The process begins when a customer places an order, and it ends when the order is successfully delivered and closed. Efficient order processing is essential for maintaining customer satisfaction and optimizing the overall supply chain performance.

Effective order processing in supply chain management requires close coordination and integration among different stakeholders, such as sales teams, warehouse personnel, transportation providers, and customer service representatives.

By streamlining and automating order processing tasks, organizations can minimize errors, reduce lead times, optimize inventory levels, and enhance order accuracy and timeliness. This, in turn, leads to improved customer service, increased operational efficiency, and a competitive advantage in the marketplace.

Download Katana’s free purchase order template

While you’re making ordering processes more efficient you may as well improve your procurement processes. Download this free PO template to minimize mistakes and ensure smooth purchasing experience.

Order processing management steps

Order processing management typically involves 6 steps. These can vary depending on the exact requirements of a particular organization but usually follow the same basic pattern:

- Order placement — This stage involves receiving customer orders through various channels such as e-commerce platforms, phone calls, emails, or in-person interactions. The orders are recorded, and customer information, product details, and order specifications are collected.

- Order processing — Once the orders are received, they undergo a verification process to ensure their accuracy and validity. This may involve checking product availability, verifying customer details, confirming pricing and discounts, and ensuring that the order meets any specific requirements or conditions. At this stage, the inventory is also checked, and the order cost is calculated.

- Order fulfillment — After the order is verified, it moves into the fulfillment stage. This involves activities such as picking the products from inventory, packaging them securely, and preparing them for shipping. In some cases, it may involve manufacturing or assembling products before they can be shipped.

- Order tracking — Once the order is prepared for shipping, it is assigned a tracking number or identifier. This allows both the business and the customer to monitor the order’s progress through various stages, from shipment to delivery. Tracking information may include estimated delivery dates, carrier details, and real-time updates on the order’s location.

- Order delivery — This stage involves handing over the order to the designated carrier or shipping company for final delivery to the customer’s location. The business may collaborate with multiple carriers or use its own logistics infrastructure. The delivery process may involve domestic or international shipping, depending on the customer’s location.

- Order completion and after-sales support — Once the order is successfully delivered, it is considered completed. However, order processing management may also include additional steps such as invoicing, payment processing, handling returns or exchanges, and providing post-sales support or customer service to address any issues or inquiries that arise.

Efficient order processing management is crucial for businesses to meet customer expectations, minimize errors, ensure timely deliveries, and maintain customer satisfaction. It often involves the use of order management systems, inventory management tools, and integration with shipping and logistics providers to streamline the process and improve operational efficiency.

How to effectively manage order processing?

If you have more than a handful of orders per day, inefficient Excel spreadsheets won’t cut it. The best way to boost your order processing management is through specialized software.

Katana is a cloud-based inventory software offering comprehensive features for order processing management. It is designed specifically for small and medium-sized manufacturers, helping them streamline their operations, improve efficiency, and gain better control over their order processing workflows. Let’s see how Katana achieves all that.

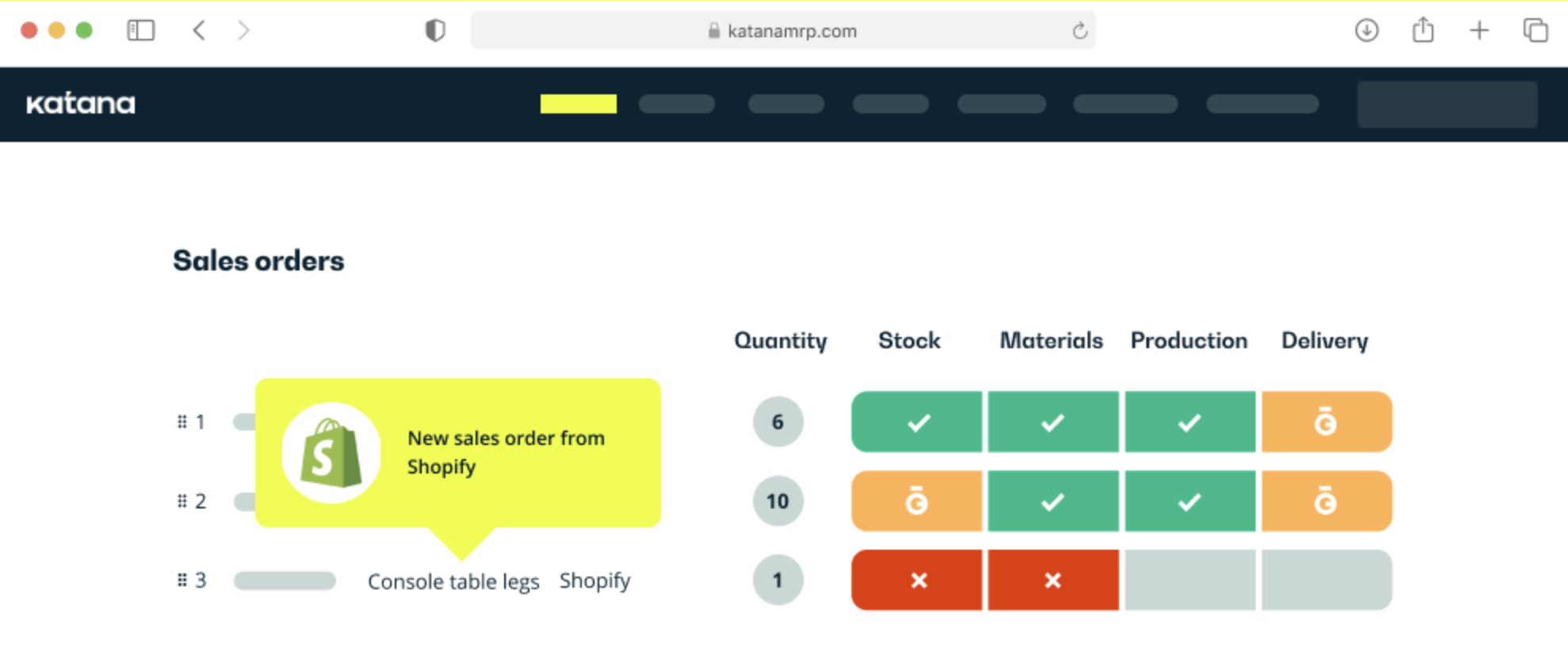

Centralized order management

Katana provides a centralized platform for order management. You can easily create and track customer orders, manage order statuses, monitor order progress, and view real-time inventory availability. This helps reduce manual errors, improve order accuracy, and maintain clear visibility into the order fulfillment process.

Inventory management and allocation

With Katana, you can effectively manage your inventory levels and allocate available stock to customer orders. Katana also lets you prioritize urgent orders, and its real-time master planner automatically reallocates the required resources to get them out of the door as soon as possible.

Katana provides real-time inventory tracking, ensuring that you have accurate information on stock levels, materials, and finished goods. This helps prevent stockouts, optimize inventory utilization, and ensure timely order fulfillment.

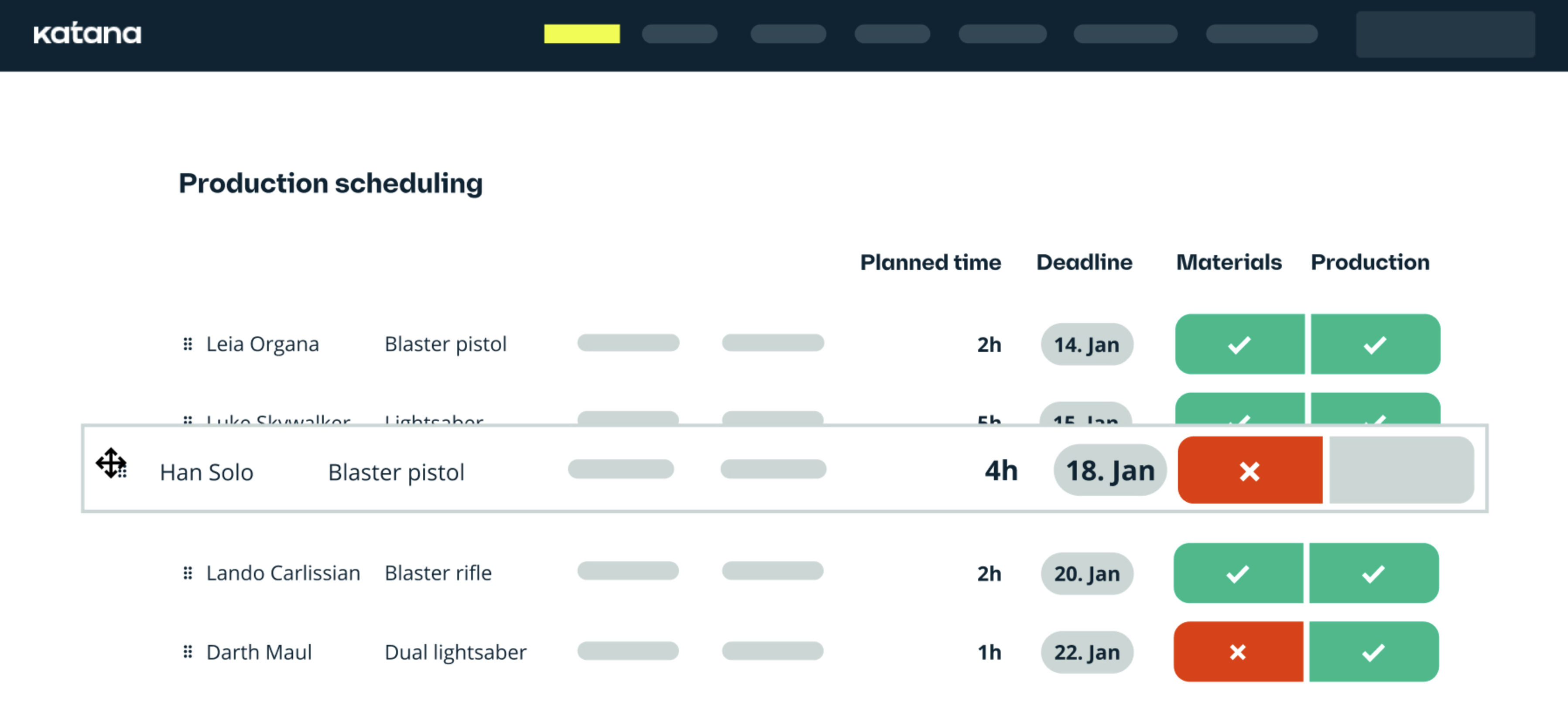

Production planning and scheduling

Katana offers production planning and scheduling capabilities, allowing you to efficiently plan and schedule manufacturing tasks based on your order backlog and available resources. You can prioritize orders, create production workflows, track progress, and manage manufacturing lead times. This helps improve production efficiency, reduce bottlenecks, and meet customer delivery deadlines.

Integration with other business tools

Katana integrates with popular business platforms such as Shopify and QuickBooks Online, enabling seamless order synchronization. These integrations automate the transfer of information between your business tools, eliminating the need for manual data entry. It ensures that your books are balanced and inventory levels and order statuses are always up to date across all sales channels.

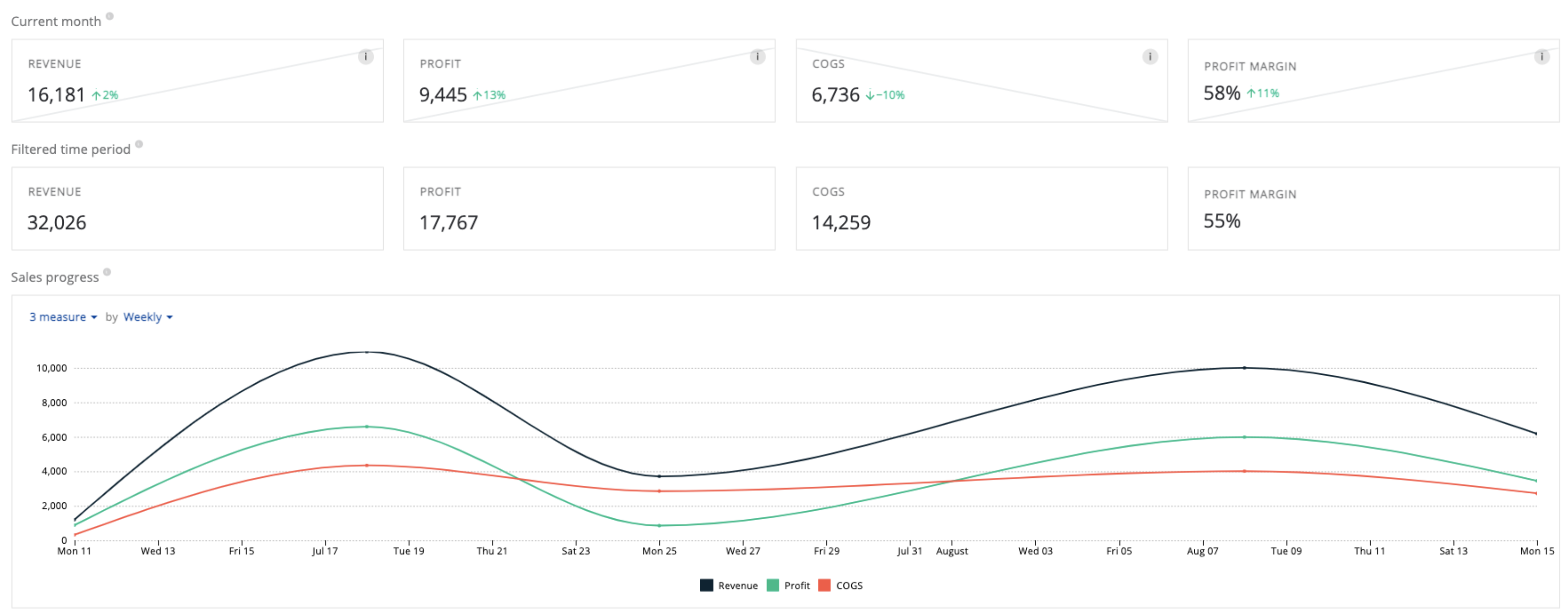

Reporting and analytics

Katana provides insightful reporting and analytics features, offering valuable insights into your order processing performance. You can generate reports on order history, production efficiency, stock levels, and more. This helps in identifying bottlenecks, analyzing trends, and making data-driven decisions to improve your order processing operations.

If you want to see Katana yourself, reach out to our sales team now and request a demo.

Henry Kivimaa

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control