Improve efficiency with partially completed manufacturing orders

Improve customer satisfaction by getting products on big orders out as soon as they’re ready by partially completing manufacturing orders.

Have you found yourself finishing a large batch of products, but it only makes up half (or even less) of the total quantity needed for a manufacturing order (MO)?

Having manufacturing orders that are partially finished, but stuck in limbo is a problem that manufacturers often encounter. When this happens it delays delivery and forces manufacturers to track what has been manufactured to avoid over or under manufacturing products while maintaining warehouse and stock levels. To help you manage these situations, Katana has rolled out an update that allows you to partially complete manufacturing orders!

Benefits of partially completed manufacturing orders

Partially completing a MO makes it possible to divide larger orders into parts. Separating the completion of an order increases your manufacturing floor’s efficiency by allowing you to pack and deliver the finished goods without waiting until the entire MO is ready to ship.

For those manufacturers who tend to create products in large quantities, the time to fully complete a manufacturing order is often longer than desired and the finished products just collect dust on the shop floor instead of being sent to the warehouse. In these scenarios, you could simply partially complete a MO, ship the finished goods to the warehouse (or directly to the customer), and continue manufacturing the rest of the products. This way, finished products don’t sit in your inventory and take up valuable floor space.

As a bonus, you can now use larger batch sizes for manufacturing orders without manually splitting MOs when you need to deliver already manufactured products.

Partial completion use cases

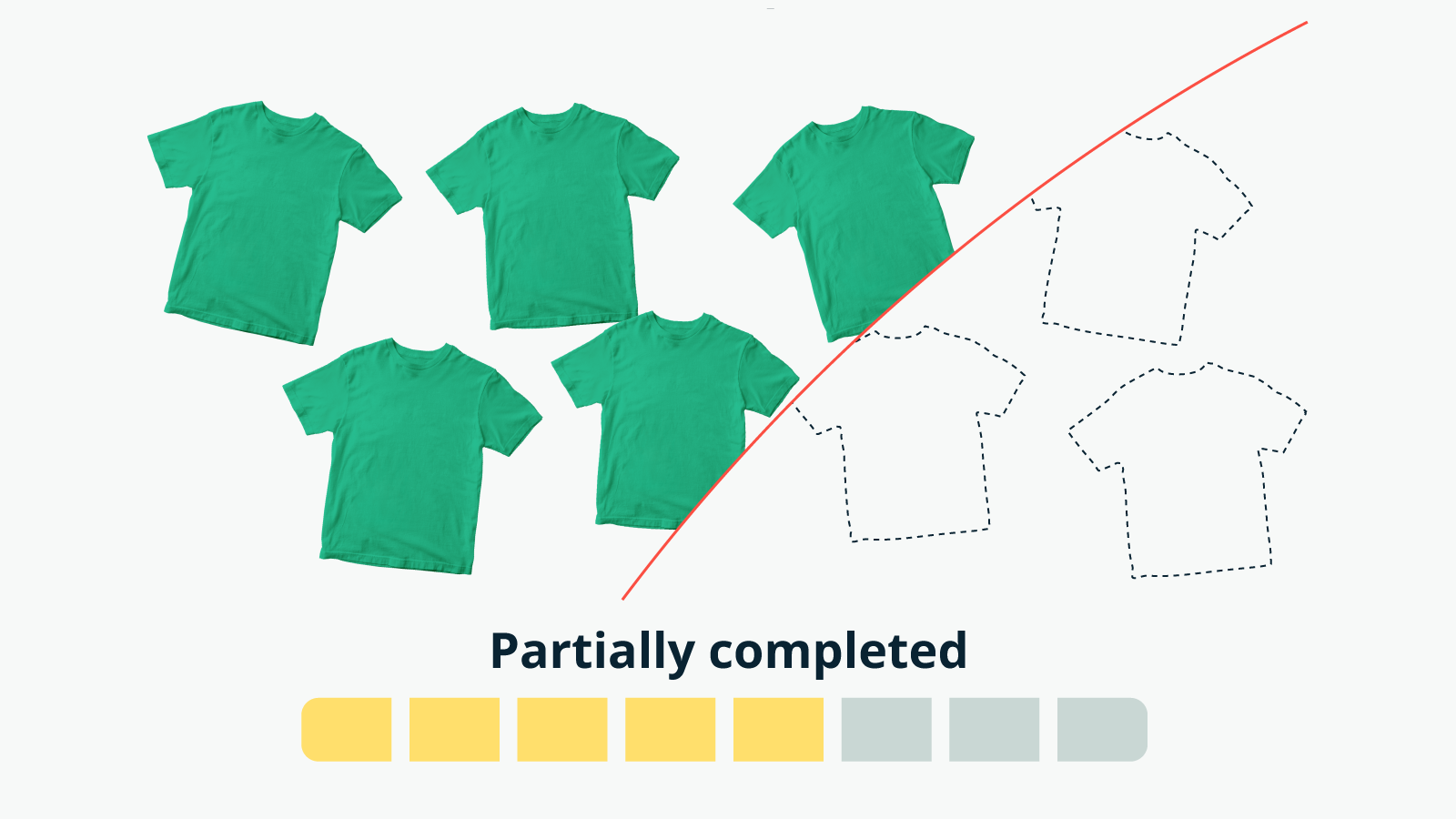

Example 1: You have a make-to-order sales order (SO) for 10 shirts and you’ve already finished 6 of them, but the rest still need more time. If you’re facing a tight schedule, you’ll want to ship products as soon as possible. With the new feature, you can Partially complete the MO and pack and deliver the 6 shirts. Your client receives part of their order early, and your stock is more organized. Once the other 4 shirts are done, you can complete the MO and send the remaining shirts to the customer.

Example 2: You’ve got a make-to-stock order for 10 shirts, connected to two sales orders: one for 2 shirts, the other for 4. Using the new feature, you could Partially complete the MO to have 5 shirts in stock. Then, Deliver all on the first SO to ship 2 shirts and complete the order. With the second SO, you can choose to Deliver some and ship the 3 shirts remaining in stock. When the last shirt is ready, choose Deliver all to close the final SO.

Partially completing a manufacturing order

All open manufacturing orders can now be updated to Partially complete or Done. If you choose Partially complete, the MO stays open and Katana will ask for the Completed quantity and the product’s completion. In the MO card, you can now find Planned and Completed tabs showing the completed and planned quantities of the products, ingredients, operations, and additional info.

Once the MO is entirely ready, change the status to Done, and Katana will ask for the final quantity of completed products, the consumed quantity of ingredients, and the consumed time for all operations. Once this is filled in, the MO will close.

To learn more about partially completing manufacturing orders, peruse our Knowledge Base article which covers all the details and guidance you need to begin.

Partial completion of MOs also works perfectly with our recently-launched partial packing delivery feature. After partially completing an order, you can partially pack as well as partially deliver a batch of products. Read about partial packing and delivery.

Partial completion combined with partial packing and delivery

Shop Floor App updates

As our team constantly works to improve the Shop Floor App to give you the best experience, the next updates will include a new search function, resource filter, and sequential operations.

Until next time, happy manufacturing!

Get inventory trends, news, and tips every month

Explore all categories

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control