Order fulfillment cycle time: how to measure and reduce it

Order fulfillment cycle time – how you can measure and reduce it. We show you how to speed up “e-fulfillment” so you can ship online orders faster than ever.

Team Katana

Order Fulfillment Cycle Time refers to the time it takes from a customer placing an order to them having it in their hands.

Are your online customers happy with the quality of your service?

Maybe you manage to get your orders shipped on time, but is there room for improvement?

Of course, your product ticks all the boxes when it comes to quality. Unfortunately, nowadays this is not enough when it comes to customer satisfaction.

Indeed, online shoppers have increasingly high demands when it comes to their whole e-commerce experience.

This is especially true when it comes to wait time for online orders. Shoppers want more convenience, quicker gratification, and many other online stores have already adapted to fit this demand.

But don’t sweat. You don’t need to bow out to e-commerce giants, when your independent e-commerce store can thrive. Streamlining your order fulfillment cycle time can help you get the most out of your e-commerce store.

Order fulfillment time is a major KPI for any business, especially when it comes to “e-fulfillment” — which brings over logistical challenges over your regular orders.

If a customer thinks they have waited too long for an order, they might not be motivated to order from you again. Even worse, they might cancel their order, wasting valuable time and production costs for your business. This may seem unfair as you place your trust in a postal or courier service to get your orders delivered ASAP.

This is why order fulfillment cycle time is an important metric for your scaling manufacturing business to track. You can figure out if it is good enough for your customer and ways to improve it.

Customers are likely to shop elsewhere if they can get goods quicker, even if the products themselves are of lower quality. This may be a bitter pill to swallow, but it is solvable for any business, no matter how big.

Your business can be known for quality and speed. It can be the go-to online store when your customer needs to buy a last-minute birthday present for their cousin. Helping people out of a sticky situation pays dividends and should make you feel great about what you do.

It boils down to the psychology of why people choose to shop at a particular place.

Emotion plays such a big role.

That is why your product alone might not be enough to build up your online sales. You also need to have utility for the customer, to give them a reason to shop online in the first place.

That is why manufacturing jargon like the order fulfillment life cycle is so important to understand. It has a profound effect on the human side of your business. You want to build your customers’ trust and be a dependable online seller. Quick deliveries show you care about your customers and you will be rewarded through positive reviews and loyalty.

Understanding Order Fulfillment Cycle Time (OFCT)

Identifying your OFCT gives you a valuable insight into the effectiveness of your order fulfillment process. This is an important metric for your business to track, as online shopping consumer data show that customer satisfaction is largely tied up in fast deliveries. Customers can be very picky when it comes to their online shopping.

The life cycle of order fulfillment encompasses many steps taken from when you receive a customer order, to the completed delivery of that order including:

- Customer places an order through your e-commerce store

- You receive the order via email or on your orders page

- You place a manufacturing order for the required goods

- Your team receives the MO and starts the manufacturing process

- The order is assembled, finished, and packed

- The order is delivered to the customer

When you are dealing with e-commerce, the order fulfillment cycle could take days or even weeks. Sometimes, it could be affected by things outside your control, such as shipping overseas. However, it is important to make sure your average OFCT remains as low as possible.

What you can control, is OFCT in the supply-chain and manufacturing sides of your business. How can you get it as low as possible by just changing things under your roof?

As your business grows, managing order fulfillment time gets more complicated. This is because order fulfillment becomes dependent on many entities in your business. Different departments start working together to complete the order fulfillment process.

These entities could be team members, workstations, warehouses, and materials. Supply chain management is about maintaining effective communication between team members and how they utilize the other parts of your supply chain.

There are many ways to work out your order fulfillment cycle meaning your OFCT can in fact refer to several metrics:

- Promised Customer Order Cycle Time – This is the expected order fulfillment time that you tell your customers. This will remain constant. Hopefully, external factors won’t permanently prolong orders, and you can streamline your order fulfillment cycle so you can lower this over time. This is a good benchmark to keep track of the other metrics below

- Actual Customer Order Cycle Time – This is the average time it takes for a customer to receive a product after ordering it. This is the everyday time that works in practice. It is what you should be aiming to reduce

- Cash to Cash Cycle Time – The time taken from spending money on raw materials and supplies to when you receive money from them as finished goods

- Supply Chain Cycle Time – How long it takes to fulfill a customer order if the requisite raw materials are at zero. It is the order fulfillment cycle time plus the time it takes to order and receive supplies

Each of these ways of measuring order fulfillment has value when analyzing your business’ order fulfillment and supply chain capacities.

Be careful not to overthink every part of your order fulfillment. It is important to understand and track what is going on in your business, but not so it deters from the running of your operations.

Measuring Order Fulfillment Cycle Time

Using an order fulfillment cycle time formula helps guide you when measuring fulfillment in your business. The most commonly seen formula works out the sum of the entire production and delivery time as follows:

Total order fulfillment cycle time = Source Time + Production Time + Delivery Time

Where source time measures the point from the customer sending their order to your business, to you having the raw materials available to start the order.

Production time refers to the amount of time it takes to manufacture, finish, and pack the order.

Delivery time is the time it takes for the order to leave your door and reach the customer’s.

For example, if a customer orders a wooden phone case online on September 25, and receives it on September 30, then the total order fulfillment cycle time would be five days.

This is informative, but does it really tell you how well you are performing on your shop floor?

You should use this to calculate each variable of the order fulfillment cycle, in order to try get your workshop running as efficiently as possible.

If the actual time takes longer than expected, then you can look into what is happening in detail.

Maybe you need a better inventory management system for small business affairs.

Perhaps your online orders page is not being checked early enough in the day.

These orders might not be being effectively communicated to your whole team.

Or even ecommerce orders are forgotten about because you haven’t put your sales orders through to your main MRP system.

Once you have worked out how to track this metric, you need to find out how consistent your business’ order fulfillment is.

There are many other KPIs that are important for your business.

For example, your orders may be reaching customers in a timely fashion, but are they arriving at your customer’s exact specifications, with full and accurate documentation, and without any damage?

Getting all this right, along with punctual delivery, is a KPI known as perfect order. It is what any online business should aspire to.

Improving the Order Fulfillment Cycle

When a customer places an order via your e-commerce channel, the order comes through to Katana and is added to the sales orders for your whole business. You can easily see which orders are from e-commerce because Katana assigns them a different code to regular orders. This lets you differentiate online orders from regular orders.

If Shopify is your e-commerce channel of choice, use a Shopify inventory integration to ease your inventory tracking and manufacturing process management.

When an online order comes in, you can plan ahead and take into account the expected delivery time into your order fulfillment cycle time. If you are shipping to another country, for example, you can use Katana to re-prioritize your list to put the overseas order at the top.

We will now take you through the process of receiving a sales order from your online store, to getting it ready to ship. You can easily organize the entire process in Katana.

You can review all open customer orders in the “Sell” screen (below).

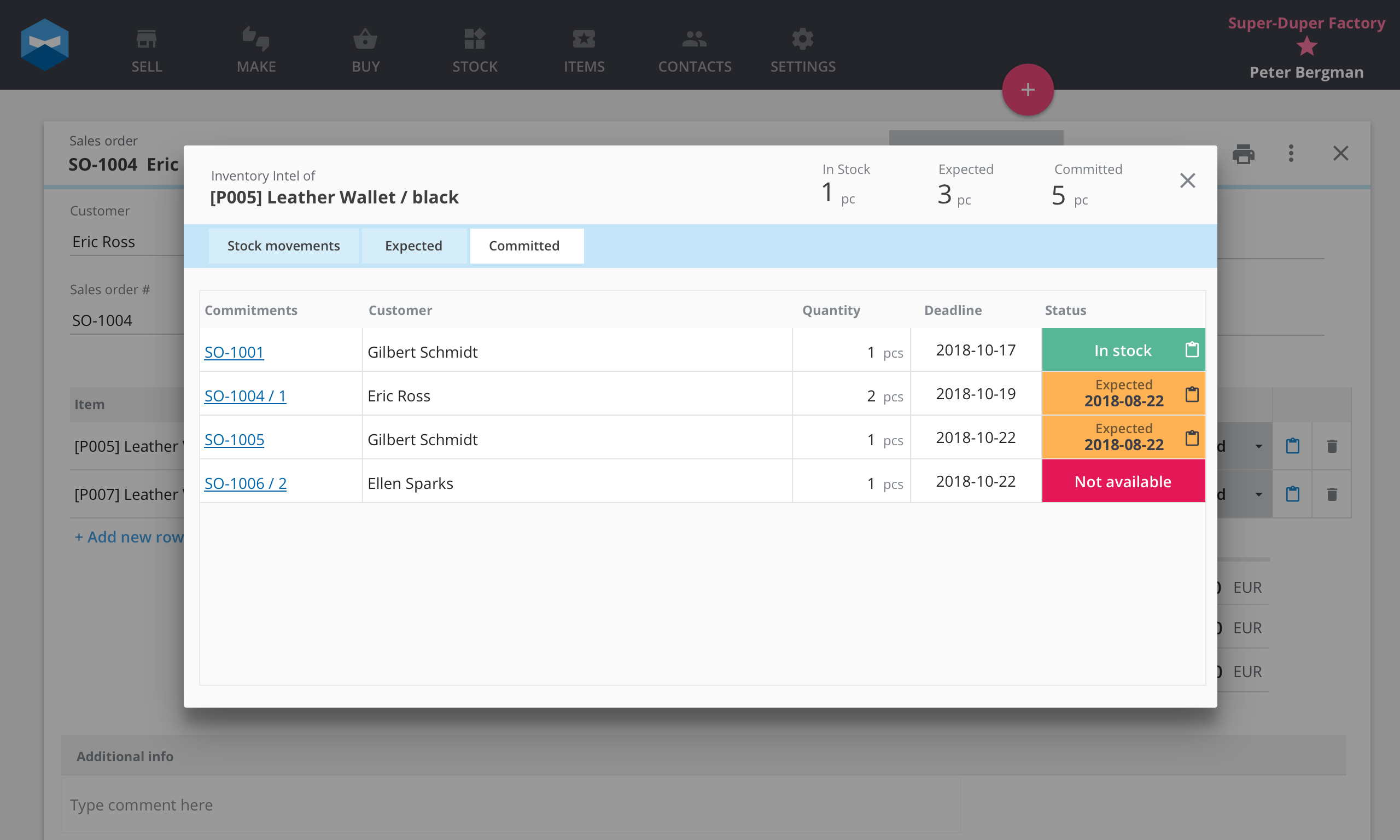

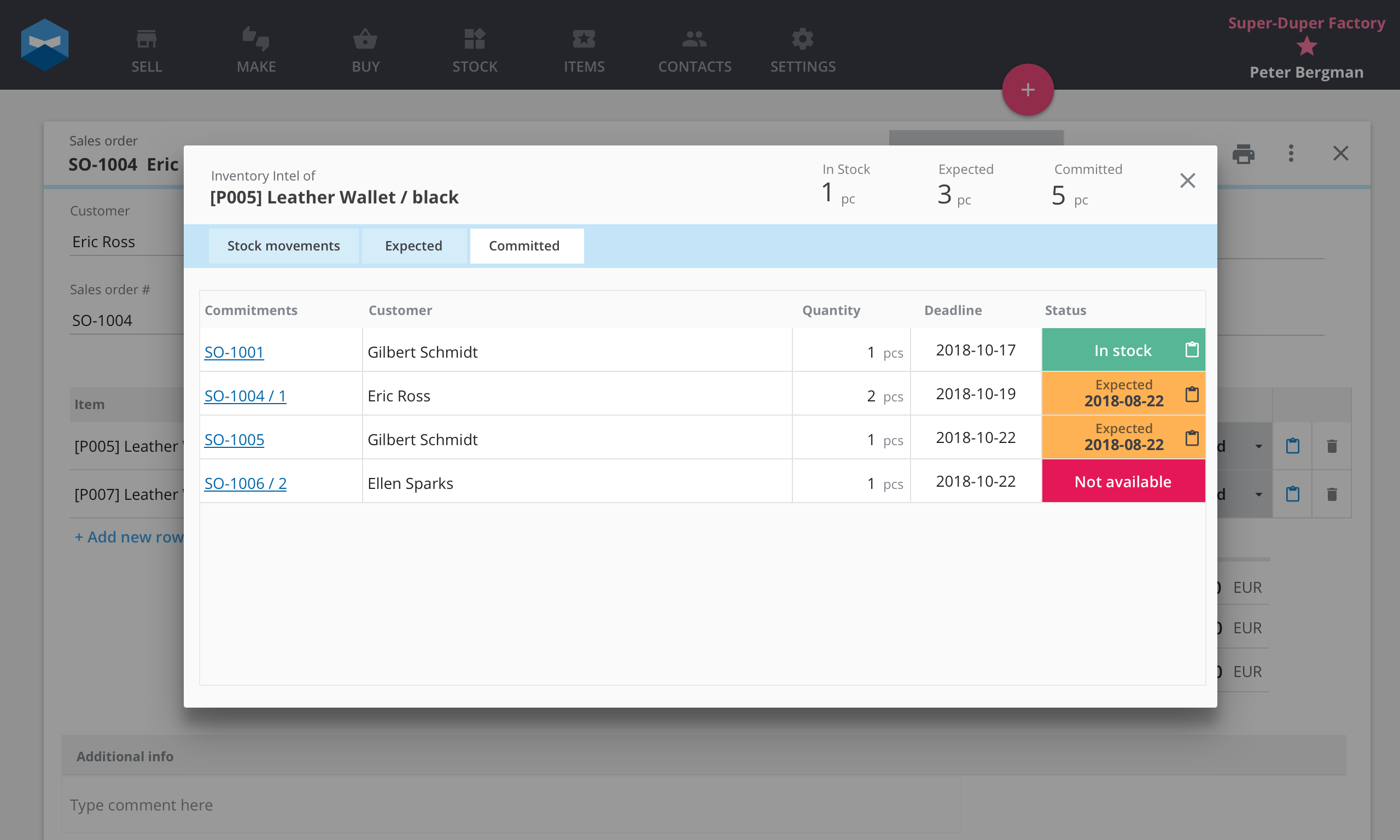

The RAG (red-amber-green) system clearly tells you the status of each sales order. Green denotes the completion of stages of the order fulfillment process (e.g. picked, packed). The numbers in amber show the expected manufacture date. Click on any sales order, and this opens a complete breakdown of it (below). You can see the whole order, with quantities. You can compare the “Expected” date seen in amber to the “Deadline” date.

Here we can see the top sales order is in stock, and the item has been committed to this order. It still shows up as it has not been packaged and shipped yet. We can see the “Expected” date for the next two orders in the queue.

Now we know which sales orders need to be completed, we can focus on the manufacturing side. Clicking on the yellow “Expected” button lets you navigate to this.

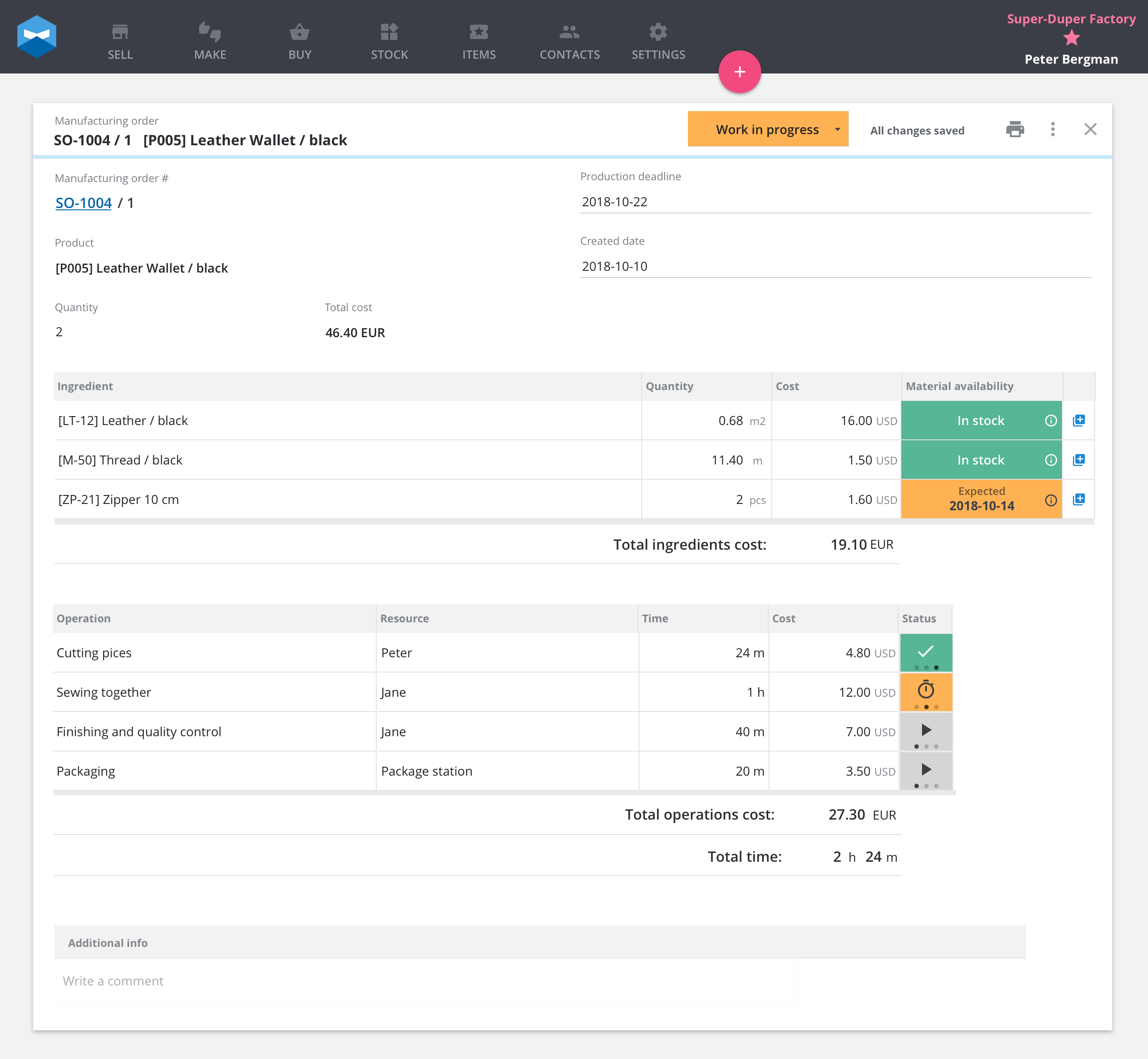

The manufacturing order window (which can also be opened from the “Make” screen) lets see the entire production process for each product in its intended order.

It breaks down that product configuration into the Bill of Materials, showing each material and quantity needed.

You can clearly see what you already have in your inventory and what needs to be ordered from a supplier.

- If it is green, then the Make Order is good to go.

- If it is yellow, then you can click on it to review the purchase order associated with that material.

- If it is red, then you know what you need to buy from one of your suppliers.

Looking at the “Ingredient” section (below) we can see that two of the three materials are already in stock. We just need a zipper. We don’t need to buy any materials, because it says “Expected”. This means the materials have been ordered, and we can complete the order when they come in.

While we are waiting for the raw materials to come in, the “Operation” section (same image, below ingredients) lets you know what you can get on with now.

We don’t need a zipper to cut the leather pieces, and as you can see, this task has been done. Katana lets you change the task status to completed, shown by the green checkbox.

This is one way you can use Katana to analyze your order fulfillment performance. You can optimize your workflow and know what can be done and when. This means you’ll be able to lower your Promised Customer Order Cycle Time.

This will have a knock-on effect for your whole business as you become a superstar manufacturer that your customers can rely on.

Katana’s smart system calculates deadlines automatically by default. If you want to manually create deadlines, you can do that to.

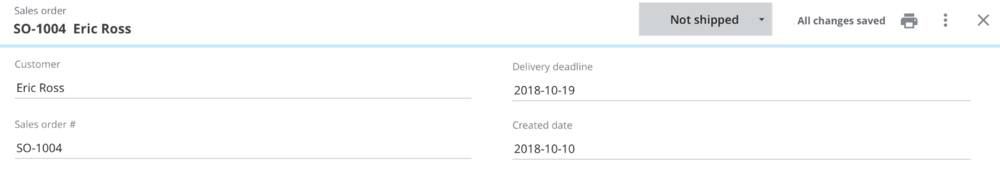

Click on any sales order to open a further information screen. At the top you can see and change the “Delivery Deadline”. Just below you can also check the “Created Date”.

Katana also gives you the option to add your own comments at the bottom under “Additional Info”.

This can be used to track order fulfillment cycle time by entering the actual manufacturing completion date.

It can then be compared with the Delivery Deadline to see if your manufacturing is ahead of the game or struggling to keep up.

This can be useful to make up for the days your order is spent in transit. If you can shave off precious time, your online store will become more favored by customers looking for your product.

Customers will leave reviews about your store if they truly had a good time dealing with it.

Many reviews mention if the order was quick to arrive, as this is a very valued attribute by customers. This will draw more customers to your site.

Your competitors will scratch their heads as they try to work out how you got the same shipping service they use to delivery quicker than them.

You can also write other notes to give feedback to your production floor about what can be improved.

Analyze your process at every point in the life cycle of order fulfillment.

How Katana Improves Your Order Fulfillment Life Cycle — Summary

- Reduce order creation time — online orders are sent straight to Katana

- Receive complete breakdowns of sales, manufacturing, and supply to deal with things one at a time

- Use Intel tools to measure and streamline your customer order cycle time

- Keep a complete record of all current and completed sales, manufactured goods, and ordered supply

- Analyze every part of your process to identify the slow parts of your order fulfillment cycle time

- Monitor the exact time each step of your order and production flow is started and completed

- Improve your workshop’s output and create your own deadlines to reflect this streamlined process

Request a demo and see for yourself how Katana can minimize your order fulfillment cycle time.

Team Katana

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control