Serial numbers to easily track and manage your finished products

Serial numbers are invaluable for companies that need complete visibility and traceability of product history and a streamlined operation.

Serial numbers ensure complete visibility and traceability of every product’s history, contributing to streamlined operations and enhanced customer satisfaction.

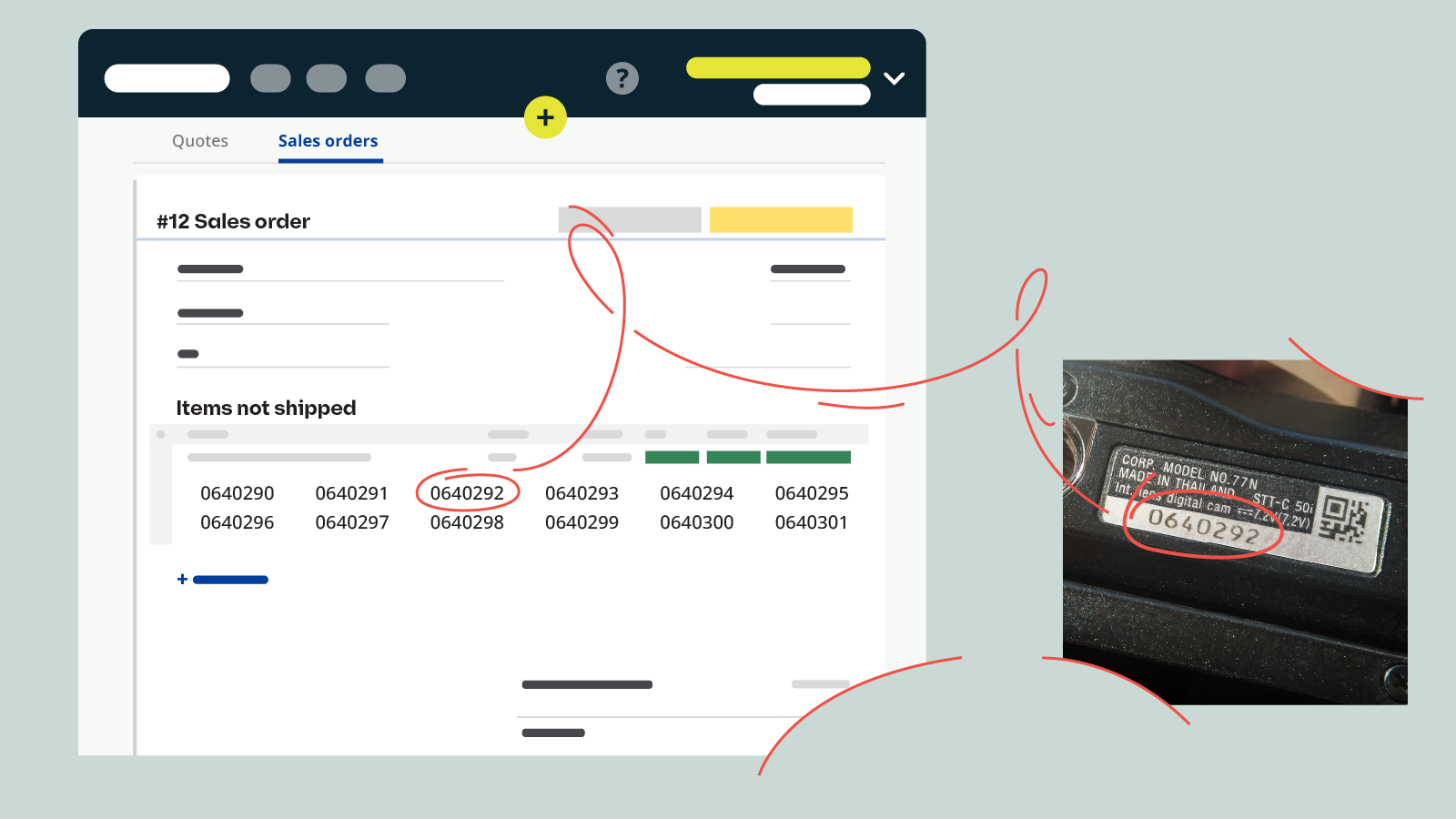

With Katana’s latest update, serial numbers are now supported on purchase orders and outsourced purchase orders. By enabling you to trace the serial numbers of sold products back to purchase orders, this update becomes particularly useful for resellers and those who outsource their manufacturing. Adding a serial number to a purchased product makes it possible to assign a unique code to each received item, meaning you can later assign the same number to a sales order.

Previously, we introduced serial numbers for finished products so that you can assign serial numbers to both manufacturing and sales orders, allowing you to efficiently track finished products via a unique identifier and monitor their journey from initial production stage all the way to the final sale.

While serial numbers are helpful in multiple industries, those in electronics, automotive, and pharmaceuticals find them crucial to uniquely identify individual products or items.

Serial numbers are useful for:

- Assisting in warranty registration, repairs, and service history

- Monitoring quality control, tracing defects, and facilitating recalls if necessary

- Aiding product support and troubleshooting

- Ensuring product integrity and identifying counterfeits

- Enabling traceability in the supply chain

Overall, serial numbers are a valuable tool for organizations to manage, trace, and identify products throughout their lifecycle, providing information throughout manufacturing, inventory management, customer service, and supply chain operations.

How serial numbers work in Katana

Katana supports three types of item traceability:

- No tracking is used if item traceability is not required.

- Batch / lot tracking allows you to assign batch numbers or lot numbers to purchased and manufactured items. This enables you to track batches for products and materials in your stock. You can also assign expiration dates to batches to give further control over the shelf life of your items.

- Serial number tracking allows you to track products using a unique identifier. This allows you to track every item’s history from the initial production or purchase stage to its sale. This is useful for warranty tracking, assistance with device support, refunds, and recalls.

Enabling serial number tracking can be done by opening an item card and choosing Serial numbers under the Product tracking section. Watch how to begin using serial numbers in Katana.

Serial numbers in Katana allow you to:

- Enable serial number tracking for finished products

- Generate (format customizable) serial numbers for manufacturing orders

- Assign serial numbers from the web app to items in manufacturing, sales, purchase, and outsourced purchase orders

- Select which serial numbers have been completed in the Shop Floor App

- Find a comprehensive overview of serial numbers for all product variants in stock

- Create stock adjustments and stock transfers for serial number trackable items

- Print documents with serial numbers

- Import and export serial numbers data

- Add serial numbers to sales and manufacturing orders via Katana’s API

Learn more about getting started with serial numbers by checking out our Knowledge Base.

You now have complete traceability of products (including their serial numbers and related stock movements), allowing you to monitor product movements throughout their lifecycle.

Happy tracking!

Get inventory trends, news, and tips every month

Explore all categories

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control