Multiple manufacturing and purchasing locations available

For a while now we have supported users with the option to track inventory at multiple sales locations. The workflow is now complete, as Katana also supports multi-location manufacturing and purchasing.

We’ve got great news! 🎉

For a while now we have supported users with the option to track inventory at multiple sales locations. The workflow is now complete, as Katana also supports multi-location manufacturing and purchasing. 💥

This (long-awaited) feature is especially useful if you manufacture at different locations or outsource some (or all) of your production.

For example, if you split production between several factories in different cities, you can now manage the manufacturing, purchasing, and sales orders for each of them separately through Katana. This results in accurate material and product inventory levels in each location. On top of that, you can also transfer stock from one location to another.

Or, if you outsource manufacturing then you could use these features to get a comprehensive overview of material levels, manufacturing activities and finished products at each of your outsourced manufacturing locations, based on the reports your partners provide.

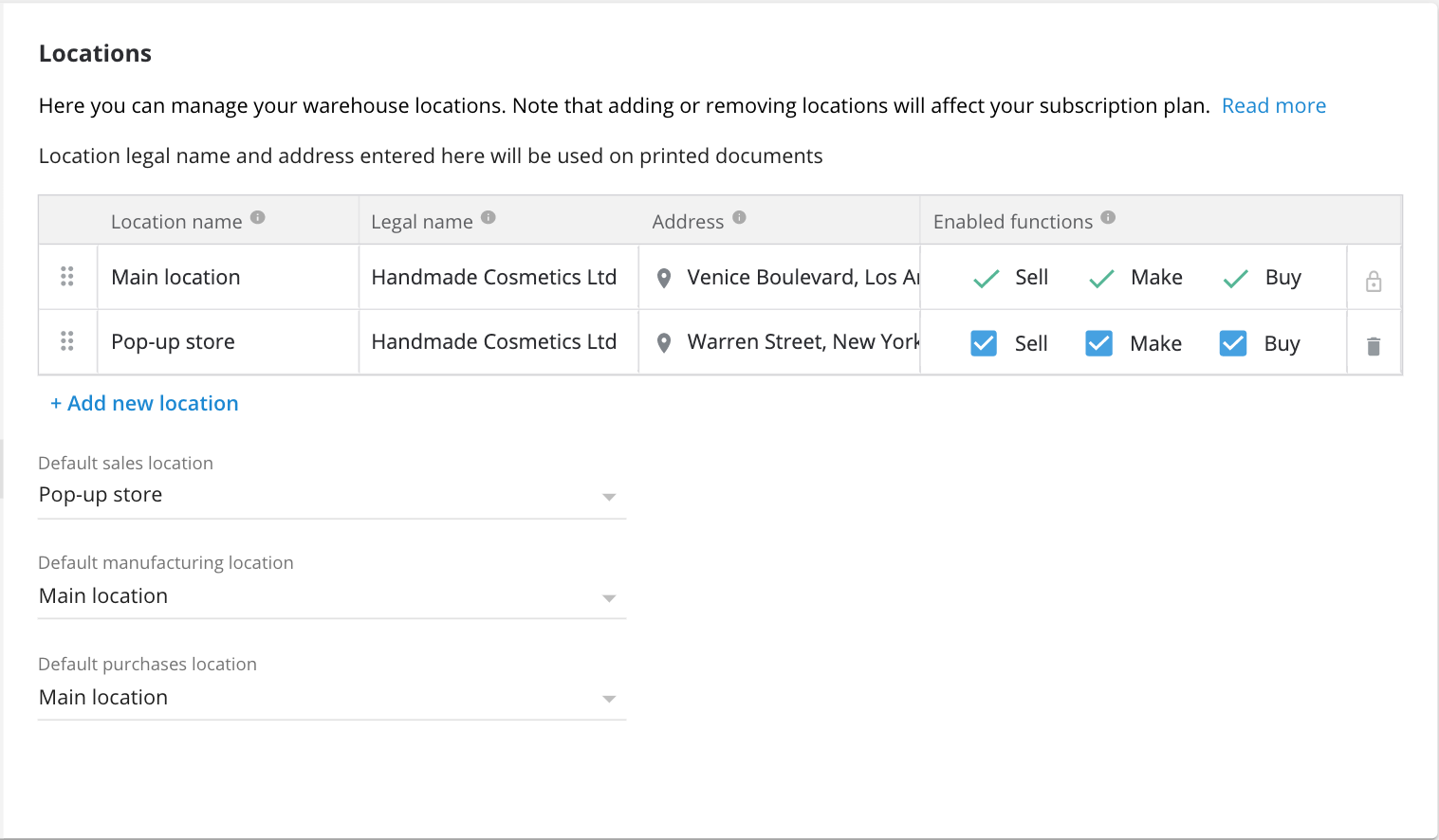

In Katana, you can now enable various functions for each of your locations: “Buy”, “Make” and “Sell”. It basically works like this:

- Enabling “Buy” means you can generate purchase orders to send materials to that location.

- Enabling “Make” allows manufacturing orders to be generated at that location.

- Enabling “Sell” allows you to fulfill your product commitments from that location to sales orders.

Here’s a neat video that shows all of this in action, with examples to suit:

Hopefully, these features make it easier for you to manage your manufacturing, purchasing, and sales at multiple locations. We know what a headache it can be without the right tools! If you have any questions, do not hesitate to get in touch.

Happy manufacturing,

Katana Team

Get inventory trends, news, and tips every month

Explore all categories

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control