D2C manufacturing in a recession: a 2022 review of holiday peaks

From recession to the Covid-19 crisis, a cascade of events has put tremendous strain on the global supply chain and economy. Download the full report based on data from real D2C manufacturers to explore key trends and actionable insights that will help you navigate economic volatility.

Download the report

Summary

In 2022, the global economy experienced its toughest set of challenges since World War II. While the residual impact of the COVID-19 crisis lingered, political unrest spurred global inflation to the highest levels since 2001. And for the next two years, it’s not expected to drop to prepandemic levels.

Combining expert consumer and market research and data from real D2C manufacturers, the report is concluded with actionable insights that can support D2C manufacturers as they continue to navigate economic volatility.

About the report

Key trends and observations from the report

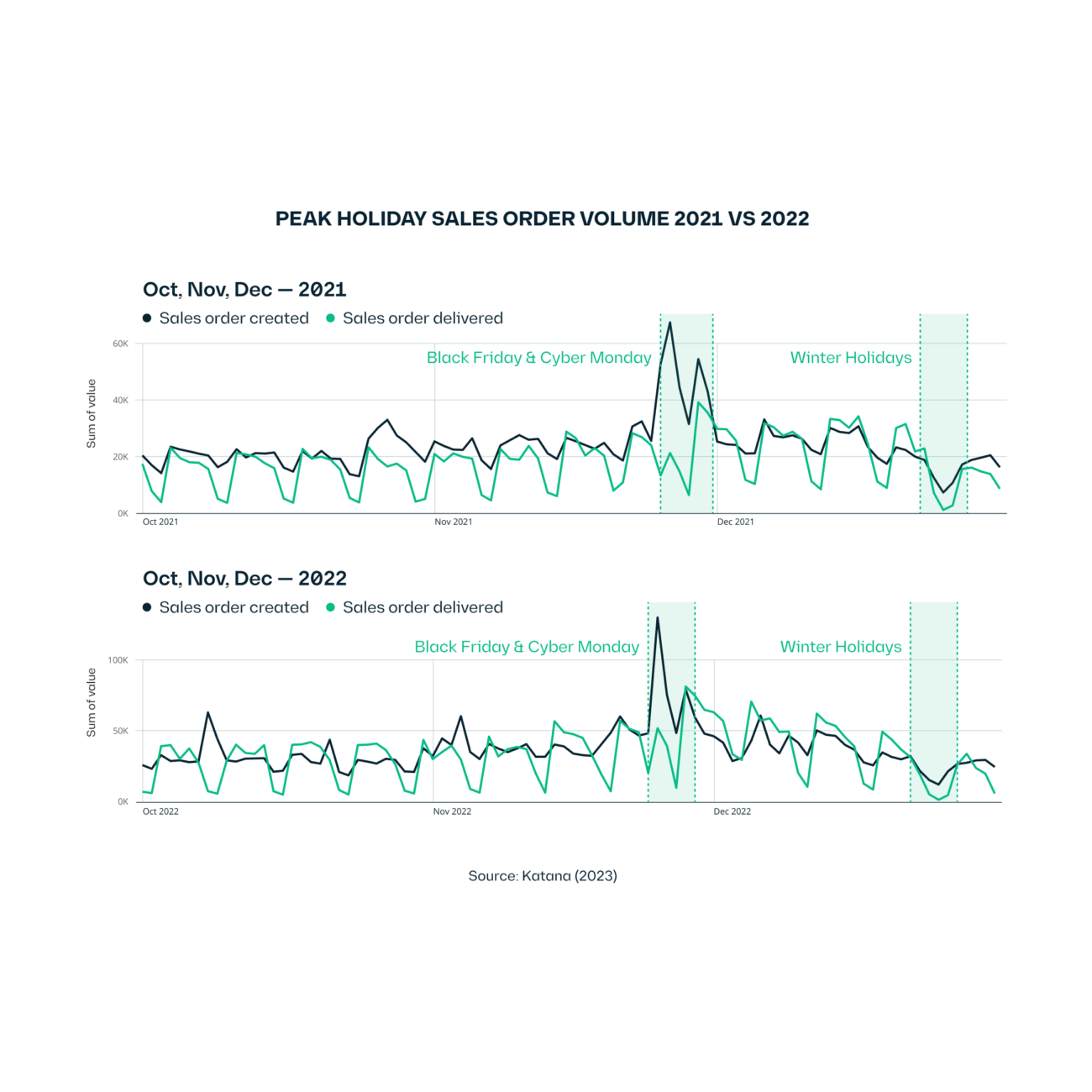

Contrary to the gloomy economic landscape, Shopify reported 17% more Black Friday sales in 2022 compared to 2021. And consumer research published by PwC cited that 74% of respondents planned to spend as much or more in 2022 than they did the year before. Consumer behavior aside, profitability and success for D2C manufacturers and retailers is still threatened by inflation, rising material costs, and more.

Key insights when looking at D2C manufacturers in seasonal industries

Black Friday and Cyber Monday are characterized by soaring online discount rates, particularly in seasonal industries where discounts range between 11-32%. E-commerce and D2C manufacturing businesses often use this as an opportunity to ride the wave of high demand. At the same time, they are also forced to compete with lowball offers for the same products.

- Forecasting demand and understanding the impact of pricing is an ongoing challenge for D2C manufacturers.

- D2C manufacturers wait until very close to peak sales periods to prepare their software and struggle to update it.

- Preparation is key to ensuring delivery despite other challenges that come with global supply chain issues.

The biggest challenges for

D2C manufacturers in

2022 and beyond

Forecasting demand and understanding the impact of pricing is an ongoing challenge for D2C manufacturers that won’t be going anywhere based on the current global economic outlook.

Issues with fulfilling sales orders during demand surges are resolved with the rightpreparation

Katana Cloud Inventory Software

Getting your products to customers faster

Katana supports your workflows no matter your industry with the features and seamless integrations you need to manage your business how you want.

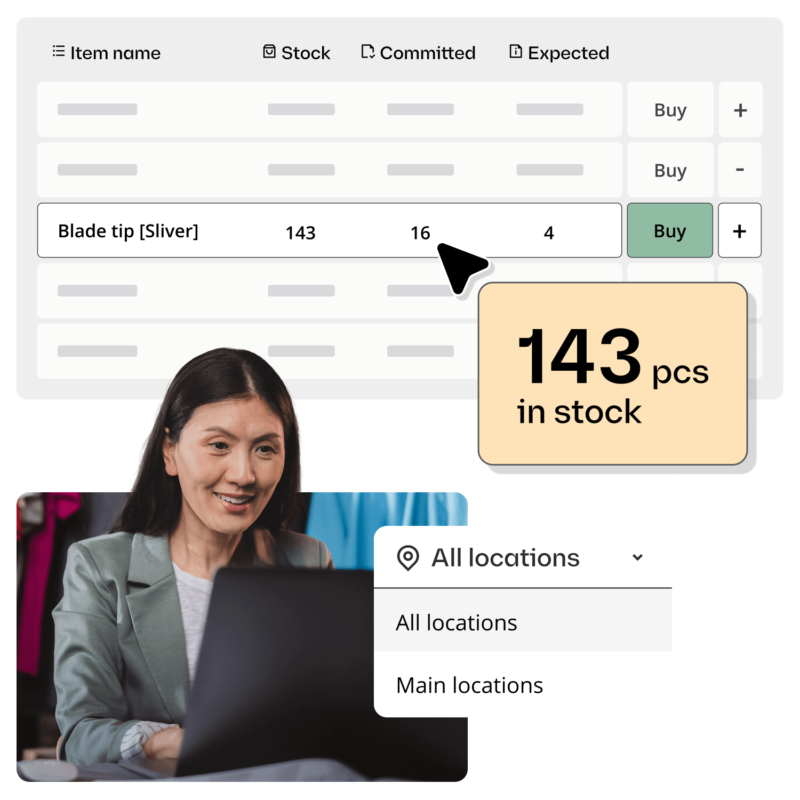

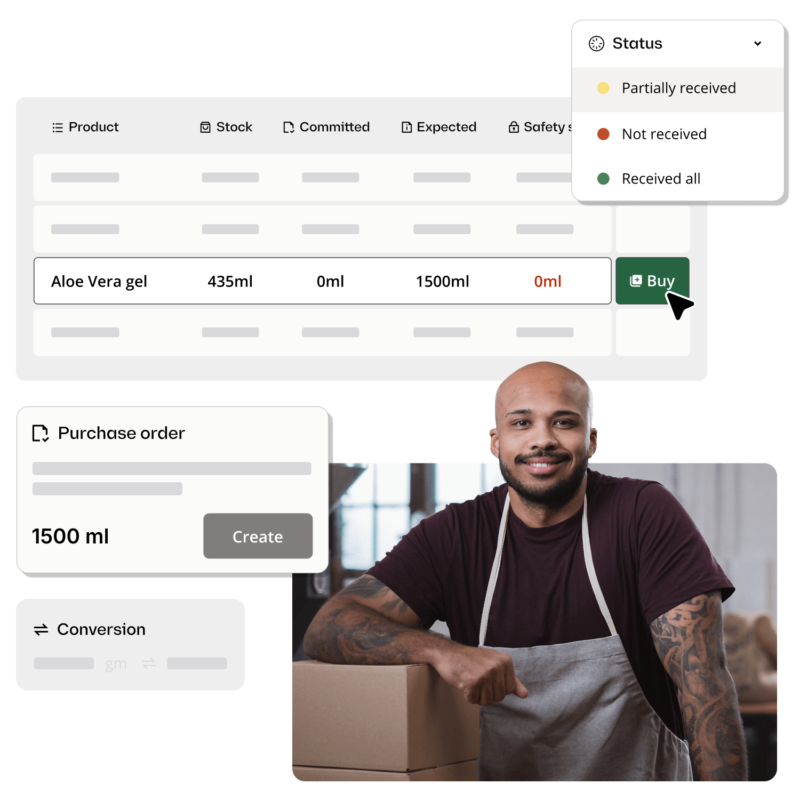

Take control of your inventory in real time

Katana’s Smart Inventory provides live, connected insights across all channels and locations — helping you maintain the correct stock levels. Track items in real-time, forecast demand with confidence, and manage costs without end-of-month surprises.

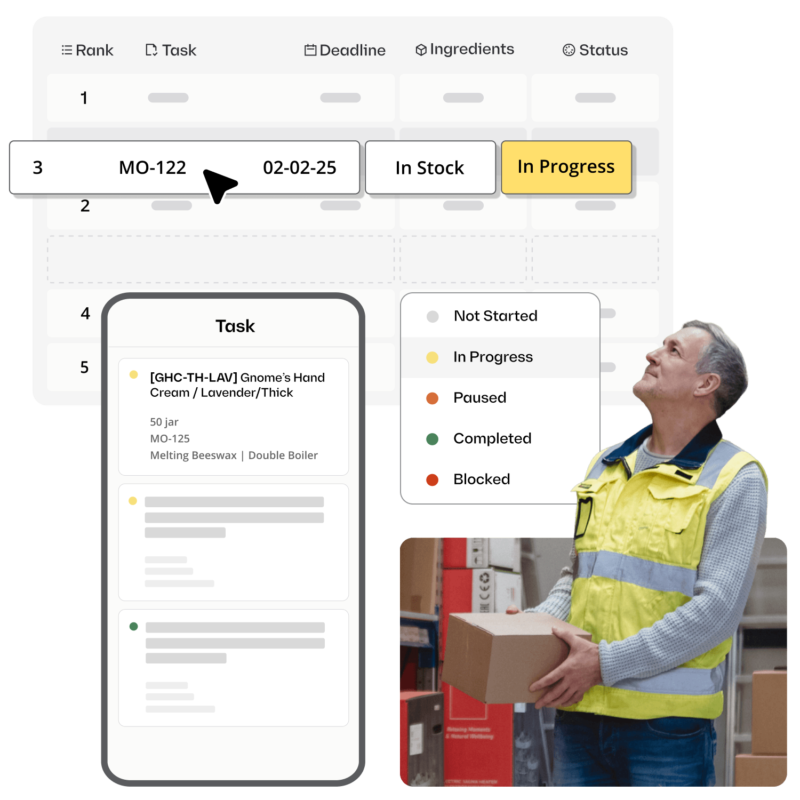

Manufacturing you can see, control, and deliver

Gain complete visibility into your entire production process. Plan capacity, allocate resources, and ensure materials are ready when needed. Live shop floor updates enable you to identify and resolve issues promptly, keeping production on track.

Stay ahead with demand-led purchasing

Track everything that’s purchased and trace its journey from supplier to production. Katana maintains a comprehensive record to support compliance, simplify audits, and facilitate prompt responses to recalls, strengthening trust in your company.

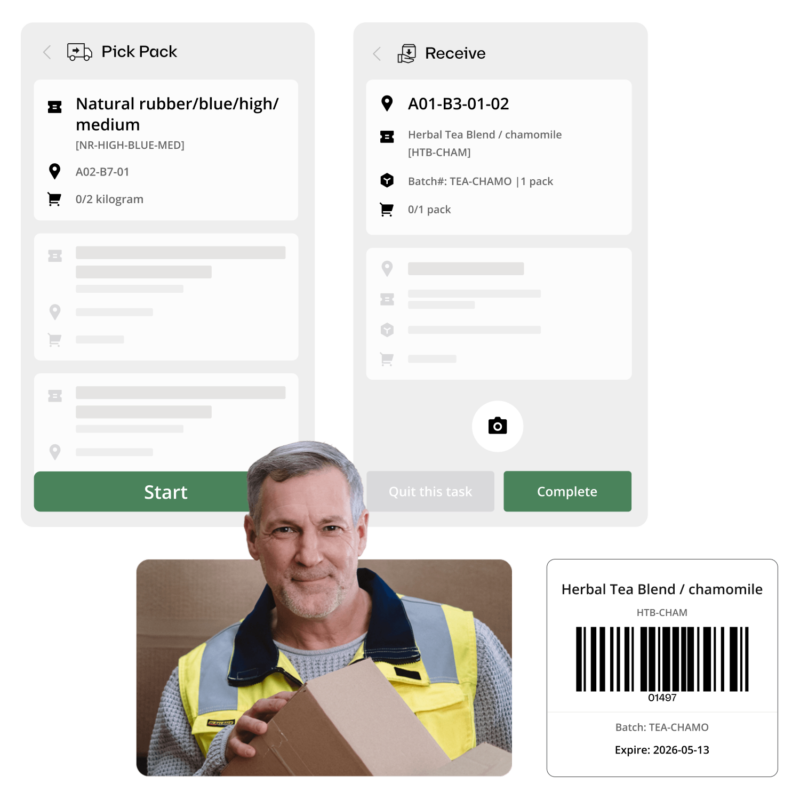

Reliably move stock in and out of warehouses

Supply your team with mobile access to real-time tasks, barcode scanning, and role-based views. The Warehouse App ensures that receiving, picking, packing, and transfers are completed accurately and on time, keeping inventory reliable and customers happy.

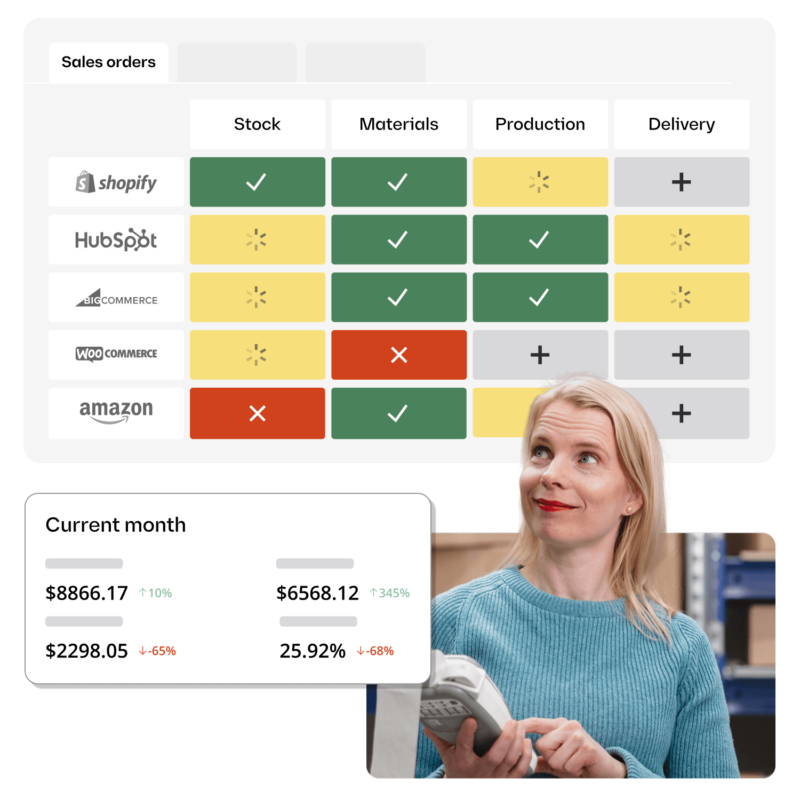

Manage orders seamlessly across all of your channels

Connect sales channels, such as Shopify, Amazon, or WooCommerce, to Katana to ensure that all orders sync automatically. Eliminate worrying about double entries, lost orders, or messy spreadsheets — just accurate, up-to-date data across every channel.

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control