Full manufacturing control

Deliver on every order with complete control of production

Manage BOMs, track shop floor tasks in real time, and keep every stage of manufacturing running smoothly in one easy-to-use platform.

+50%

on-demand product range increase with Katana, enabling expansion into the new market

Losing track of what’s happening on the floor?

Get real-time visibility from raw materials to finished goods, so you always know what’s in progress and what’s done.

Hard to keep production on schedule?

Assign tasks, monitor progress live, and prevent delays with clear shop floor insights for every order.

Errors piling up between teams and shifts?

Connect planning and execution in one system to reduce mistakes, cut waste, and keep every run consistent.

Stop manufacturing delays before they happen

Get a clear picture of your production at every step. Bring materials, tasks, and order status into one system, prevent bottlenecks and keep orders moving.

Deliver every order on time with complete production visibility

Track every task, material, and cost in real time with Katana’s manufacturing tools so production stays smooth and every order ships on schedule.

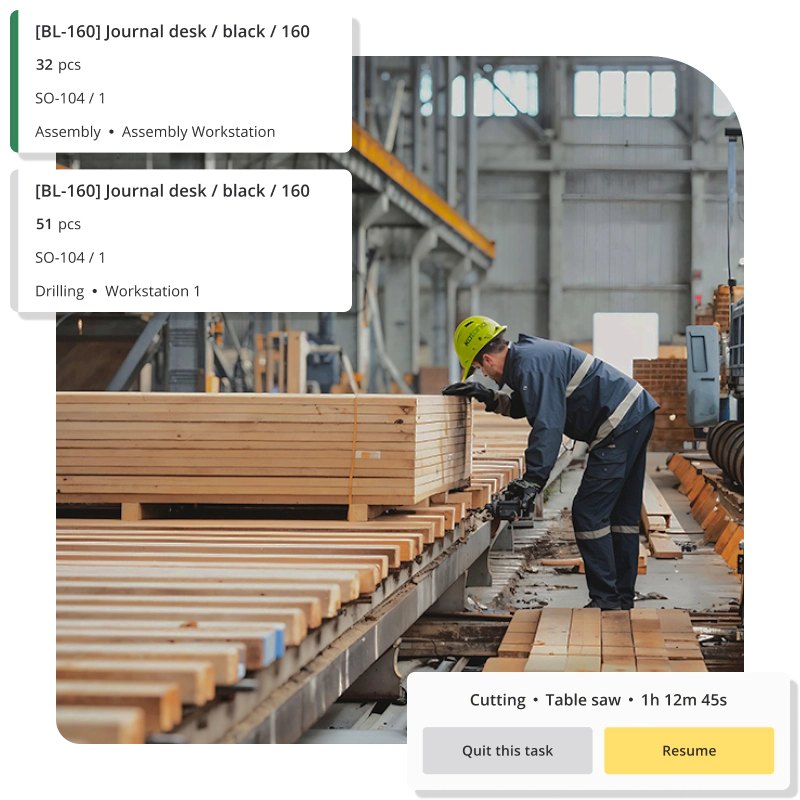

- Shop Floor app: track progress and tasks in real time directly from the shop floor

- BOM and subassemblies: build accurate recipes to produce even the most complex products

- Manufacturing cost calculations: monitor costs as work happens and keep margins under control

- Contract manufacturing: manage outsourced production alongside your in-house operations with full visibility

- MTS and MTO workflows: handle make-to-stock and make-to-order seamlessly in one system

- Role-based access: keep every user focused and secure with access tailored to their role

Prevent stockouts and keep production flowing effortlessly

Get real-time visibility into stock and materials with Katana, helping your team plan confidently and keep production moving without delays.

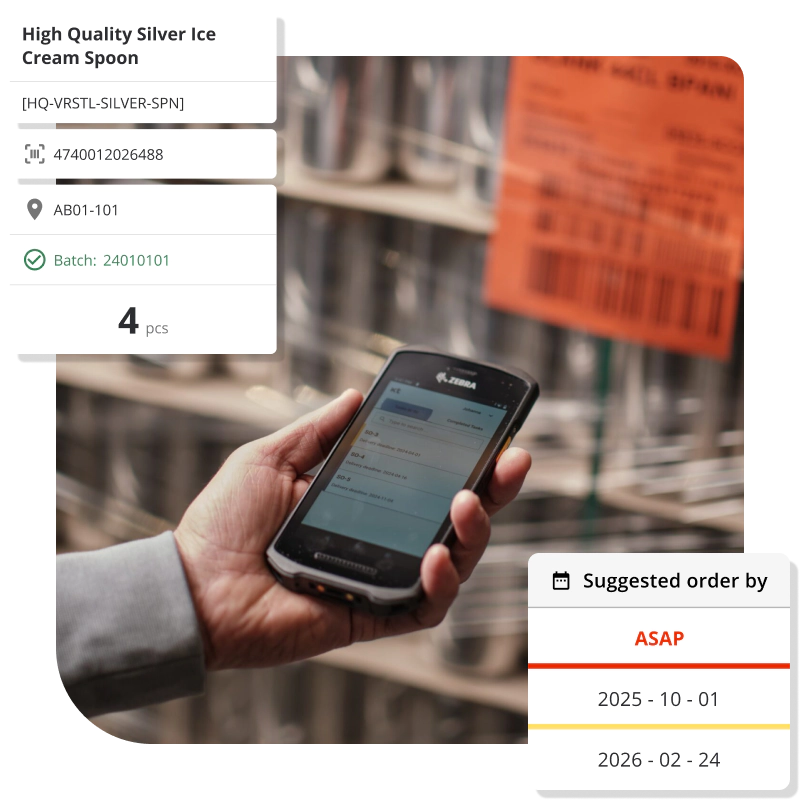

- Real-time inventory management: see live stock levels for materials and products across all locations

- Barcode scanning: record stock movements instantly for faster, error-free updates

- Planning and forecasting: predict material needs and plan production with confidence

See it for yourself

Take a look at the interactive demo to see how Katana can help organize your inventory and manufacturing processes and give you a clear overview for making informed decisions.

Features

Everything you need for production control

Easily track batches, expiry dates, and serial numbers while fulfilling orders across every channel. Katana builds traceability into your daily workflows, so meeting requirements is effortless.

Shop Floor App

Give your production team clear task lists, priorities, and instructions directly on the shop floor with no limits on the number of users. Track progress in real time and ensure every order moves smoothly from start to finish.

BOM and Subassemblies

Create and manage bills of materials, including subassemblies, to ensure accuracy in production. Keep every component and process organized for consistent quality and easier scaling.

Insights for real-time planning

Access live production and inventory data to make quick, informed decisions. Adjust schedules, allocate resources, and respond to changes without slowing down operations.

Manufacturing cost calculations

Automatically calculate manufacturing costs based on your BOMs, operations, and material usage. Compare planned and actual consumption to get accurate margin insights and make smarter pricing and production decisions.

Contract manufacturing

Track outsourced production alongside in-house operations. Monitor timelines, costs, and quality so you can maintain control and consistency across every manufacturing partner.

Real-time inventory management

Track material availability and the consumption of ingredients as production happens. Ensure stock levels are accurate, materials are replenished on time, and production never stalls due to shortages.

Role-based access

Control what each team member can see and do within Katana. Shop floor operators only see their assigned tasks, helping them stay focused, while sensitive data remains protected and everyone has the tools they need to work efficiently.

MTS and MTO workflows

Manage both make-to-stock and make-to-order production in one system. Switch between workflows or run them side by side to match demand and optimize resources.

Barcode Scanning

Speed up shop floor processes with barcode-enabled material tracking. Use scanning to find ingredients, add them, and report consumption accurately while keeping your system instantly updated.

Industries

These industries rely on Katana to keep products moving

Metal fabrication

Gain full visibility from raw materials to finished parts. Katana helps you plan production, track jobs in real time, and keep every order on schedule.

Industrial machinery and equipment

Manage complex builds with confidence. Katana connects BOMs, routing, and shop floor data so you can stay on top of every component and cost.

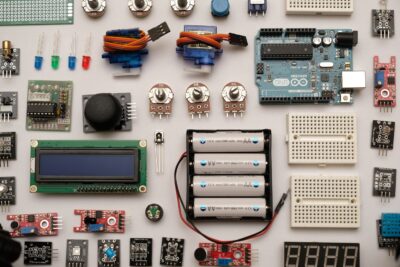

Electronics

Control every step of assembly and production. Katana gives you traceability for components, batches, and serial numbers, so nothing slips through the circuit.

Automotive

Stay in control of multi-stage builds and part tracking. Katana helps you manage orders, operations, and inventory across every model and supplier.

Real results from real people

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control