Outsourced purchase orders — assign batches to ingredients

Gain additional visibility into your work with contractors by assigning batches to ingredients and customizing recipe rows through Katana’s API.

In case you missed it, we introduced a new workflow inside Katana for manufacturers who work with contractors. This contract manufacturing (aka outsourced manufacturing) feature allows you to track materials in your partner’s location and receive orders with accurate cost value.

With this feature now established, we’re moving forward and rolling out an improvement that enables you to assign batches to ingredients for your outsource purchase orders (OPOs). Katana API users will also be able to customize OPO ingredient rows.

What has changed?

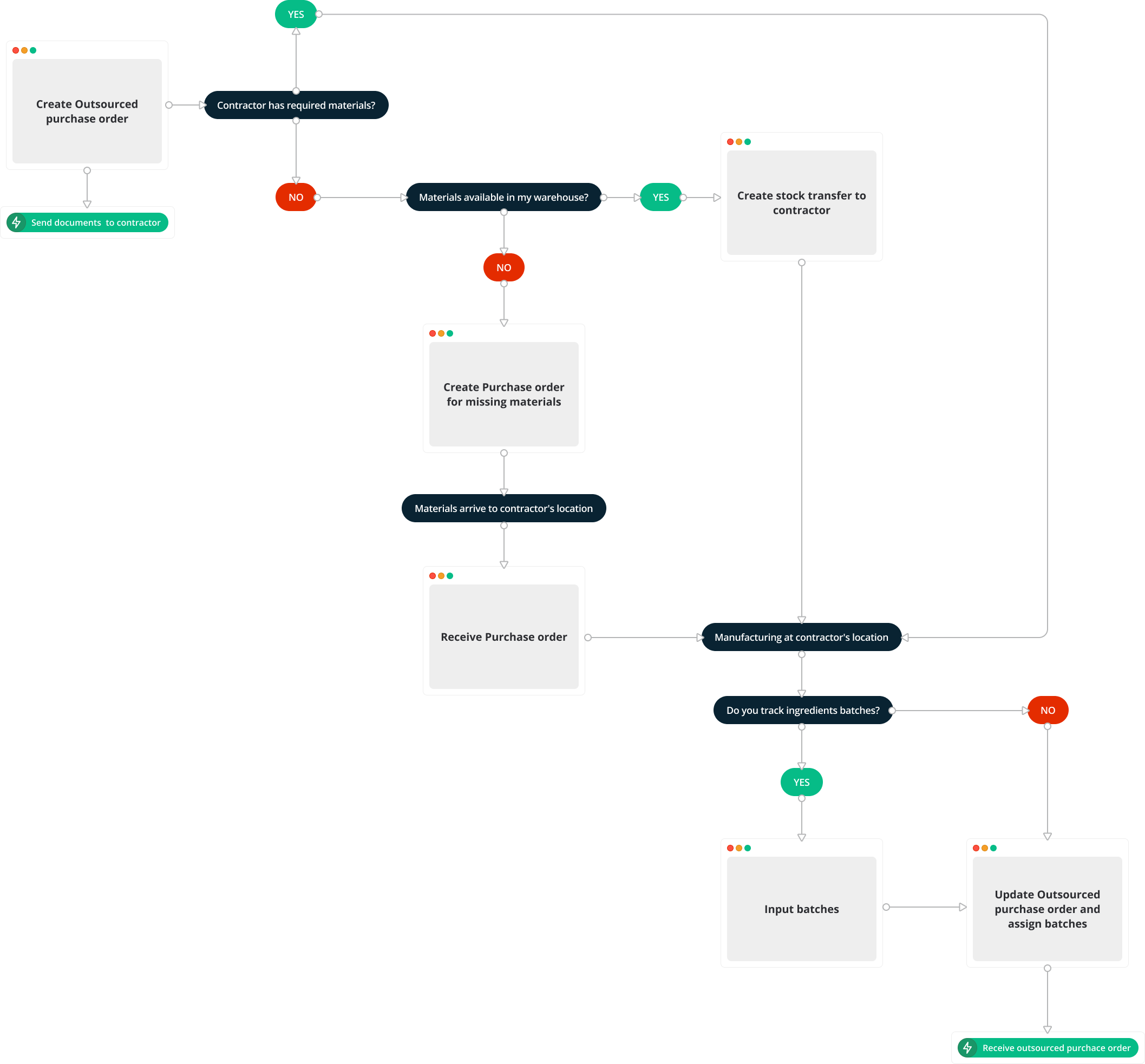

First, this change is because manufacturers who use an outsourced manufacturing model may require material batch-tracking in their workflows.

Now, you’ll no longer need to make stock adjustments to fix ingredient batch levels, just scan the barcode or assign the batch information manually before receiving the OPO. Check our Knowledge Base article for more about batch tracking on outsourced purchase orders.

In addition, Katana API users can modify the whole OPO card via API. You can now customize (add, delete, or update) OPO ingredient rows with this update. Learn more about Katana API.

What’s next?

Our team is already working on improvements that will make communication with contractors easier, allowing you to send purchase and outsourced purchase orders via email. Stay tuned!

Happy contract manufacturing!

Get inventory trends, news, and tips every month

Explore all categories

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control