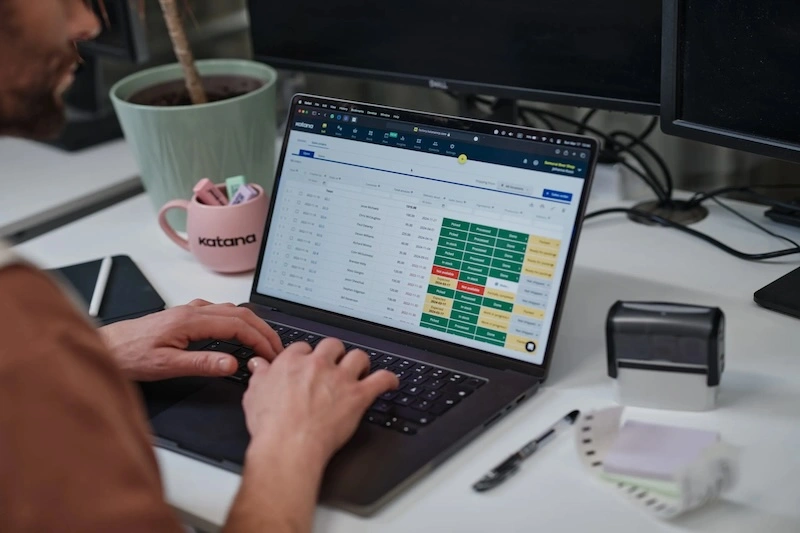

Advanced Manufacturing add-on

Implement lean operations with Advanced Manufacturing

Track, schedule, and report the progress of your manufacturing operations. Book a call with your Katana Customer Success Manager and try out the Advanced Manufacturing add-on with a 14-day free trial.

Add resilience to your manufacturing process

Today’s manufacturing demands more than product creation — it requires meticulous planning, consistency, and insight.

Becoming a successful manufacturer is no easy task. Not only are you trying to continuously optimize production, but you’re also trying to improve resource management and profitability, which requires detailed cost breakdowns from labor to materials. Katana’s Advanced Manufacturing add-on allows you to manage the complexity of production sequences while providing a comprehensive view of production costs.

The Shop Floor App is now essential for our business in maintaining and ensuring smooth, scalable operations.

Hayden Deatherage

COO at Sherpa Equipment Company

Increase your time to market with the Advanced Manufacturing add-on

From tracking to reporting capabilities, enhance your productivity and optimize your supply chain.

Ensure production quality and consistency

Streamline production from start to finish with powerful tools that ensure every step is precise, visible, and quality-driven.

- Manufacturing routing & sequencing

Organize operations in the exact order your process needs to ensure accuracy and consistency on the shop floor. - Real-time ingredient picking

Virtually pick ingredients from stock the moment they’re used in production. - Built-in quality checkpoints

Guide operators step-by-step via Shop Floor App to ensure consistent output and accurate labor reporting.

Get an overview of resources and costs

Gain full clarity into your production performance with insights that help you stay efficient, cost-effective, and in control.

- Advanced manufacturing insights

Dashboards compare planned vs. actual material and labor usage so you can spot variances early, trim waste, and keep jobs on budget. - Flexible cost models

Capture setup, per-unit, and fixed costs for each operation to reflect true production spend, regardless of volume or complexity.

Frequently asked questions

The advanced manufacturing add-on is available to purchase on the Standard, Professional, and Professional Plus plans. If you are on the Starter plan, you have to upgrade to Standard or higher to purchase or gain access to this add-on.

You can access and try this add-on during a 14-day trial. After this period, the account owner can purchase it. The cost of the add-on is $199/month on the Standard plan, $449/month on the Professional Plan, and $999/month on the Professional Plus plan.

If you are interested in purchasing the advanced manufacturing add-on, please fill in the form below to book a meeting with one of our Customer Success Managers, who will provide full guidance and support in setting up and adopting advanced manufacturing.

The Advanced Manufacturing add-on varies in price with our different plans because of the direct correlation between plan tier and expected usage. As you move to a higher-tier plan, it’s designed to support larger operations, which typically involve higher volumes of manufacturing processes, more complex operations, and a greater demand for data processing resources.

Yes, you and your team can access and test the add-on for 14 days. This trial comes at no extra cost, and if everyone is happy with the add-on, the account owner can add advanced manufacturing (or any other add-on) to your plan, and your business can continue to use the advanced manufacturing features.

Important: The account owner is the only one who can purchase add-ons in Katana. If the owner cancels the 14-day free trial, the add-on is removed. If the account owner doesn’t cancel the 14-day free trial before the trial period ends, the add-on will appear in future invoices.

Step 1: Resource allocation

Start by reviewing how you allocate resources to manufacturing. Think about the most efficient way to plan and track the time, cost, and quantities involved in each step of production. Advanced Manufacturing supports various types of operations to meet these needs, allowing you to accurately assign manufacturing costs directly to your finished products.

Step 2: Mapping manufacturing steps

Map out each manufacturing step for your products, noting the sequence and whether steps happen one after another or simultaneously. Defining this sequence ensures that your team follows the exact order of operations to work efficiently without constant interruptions. Consider creating a flowchart to visualize these process steps, as this can help you decide on the types of operations to use.

Step 3: Empowering Your shop floor team

Identify the roles of your shop floor team and enable the Shop Floor App for each team member involved in any production step. This app helps you manage inventory and costs, keeps communication direct, and allows you to catch and address problems early before they become unmanageable.

Step 4: Appointing a master user for the Shop Floor App

Assign one team member on the shop floor to become the “master user” of the Shop Floor App — someone who thoroughly understands its features and functions. Having this go-to person on the shop floor makes it easier for other team members to adopt and use the tool effectively.

With everything in place for success, you can step back and let your team manage the daily manufacturing tasks, allowing you to focus on strategic goals. Occasionally, you should review manufacturing insights to spot any patterns in production history, as these may reveal opportunities to increase output with existing resources or cut costs on underused materials.

Book a call to get started

Discover how the Warehouse Management add-on can transform your operations. Improve efficiency, eliminate errors, and elevate customer satisfaction. Book a call now to learn more!