What is cycle inventory? Here’s everything you need to know

In the world of inventory management, one of the most important things to have control of is your cycle stock.

This inventory is used to fulfill customer orders and keep production running. By forecasting correctly and maintaining a proper level of cycle inventory, businesses can avoid the costly consequences of stockouts or obsolescence and generating dead stock. In this guide, we’ll walk you through the following:

- A definition of cycle stock

- How it differs from safety stock and cycle count

- Factors that impact cycle inventory

- The cycle inventory formula

- Inventory management software and how it can help

Let’s dive in.

What is cycle inventory?

Cycle stock is the inventory necessary to keep production running and customer orders fulfilled. This includes the raw materials used in the manufacturing and the finished products waiting to be shipped.

To calculate cycle stock, businesses need to consider both manufacturing lead time demand and production quantity. Lead time demand is the amount of time it takes for an item to be delivered from a supplier — or for a raw material to be delivered from the point of production.

Production quantity is the number of units produced during each production run.

Cycle stock vs. safety stock

Importantly, cycle stock does not include safety stock.

Safety stock is the inventory buffer that’s maintained to protect against unforeseeable disruptions, like supplier delays or natural disasters. On the other hand, cycle stock is based on predictable, forecasted customer demand and production schedules. While both are important for a well-run operation, cycle stock is often the focus of inventory management because it directly impacts working capital.

By contrast, safety stock levels are usually set by senior management and are not as subject to change.

Cycle inventory vs. cycle count

It is also not to be confused with cycle count, which is the practice of physically performing a stocktake regularly (daily, weekly, monthly, etc.). Cycle count is vital for maintaining accurate stock levels, but it’s a different process than cycle inventory management.

Notably, it usually does not measure the entire inventory but only a sample, providing a projection for the total.

Why is cycle stock important?

One of the worst things that can happen to a company is a stockout. This is when inventory runs out, and customer orders can’t be fulfilled. Stockouts can have a major impact on businesses:

- Lost sales — When customers can’t get the products they want, they’ll go to a competitor. This leads to lost revenue for the business

- Damaged reputation — Stockouts damage reputation because it shows that the company isn’t able to meet customer demand. This can lead to long-term damage as customers may never come back

- Inefficient production — If the inventory isn’t available, production will have to stop. This leads to inefficiencies and can cause further disruptions down the line

It’s important to note that stockouts don’t just happen because of low inventory levels. They can also be caused by poor planning, inaccurate forecasting, and inefficient processes. This is why cycle inventory management is so important. By having a good handle on your cycle stock, you can avoid the costly consequences of stockouts.

Factors that impact cycle inventory

Your cycle stock levels are impacted by the following factors:

- Customer demand — This is the most important factor in forecasting cycle inventory. If customer demand is high, businesses will need to maintain higher levels of stock

- Supplier lead times — Longer supplier lead times will require businesses to order inventory further in advance, increasing cycle stock levels

- Production quantity — If a business can produce more units per production run, it’ll need less inventory on hand to meet customer demand

- Production lead time — Longer production lead times will require businesses to order raw materials further in advance, increasing cycle stock levels

- Seasonal changes — Seasonal changes in demand can impact cycle inventory levels. As a cycle inventory example, a business selling winter coats will need to maintain higher levels of stock in the months leading up to winter

What is inventory cycle time?

It’s the number of days (or weeks, or months) between receiving raw materials and the shipment of finished goods. In other words, it’s the length of your production process.

You can see how maintaining an accurate cycle inventory can be a challenge, as there are a lot of moving parts. There is also the factor of storage costs to consider, which will lead companies to try and minimize their average cycle inventory while not risking any stockouts.

To make it a bit easier to maintain optimal inventory levels, let’s look at the cycle stock formula.

What is the cycle inventory formula?

The struggle to keep inventory costs to a minimum while also never finding yourself out of stock can be daunting. The most common way of calculating cycle inventory levels is through economic order quantity (EOQ).

The formula for EOQ is:

EOQ = √[2(DK/H)]

In this equation:

- D is the annual demand in units

- K is the fixed cost per order

- H is the annual carrying cost per unit

That may still seem a little complicated, so let’s break it down with an example.

Our hypothetical company FakeFuniture sells, on average, 3,000 wicker chairs every year. It costs them $100 every time they place an order, and a chair has a carrying cost — that is, how much it costs to keep it warehoused — of $10 per year.

That would mean the EOQ is the square root of 2(3000 x 100)/10, which equals 245. The ideal number for the company to order each time would be 245 units, meaning they would need to place a new order every 30 days or so in order to maintain their 3,000 units sold for the year.

Now that you know how to calculate cycle inventory, let’s move on to software and explore how it can help you with inventory management.

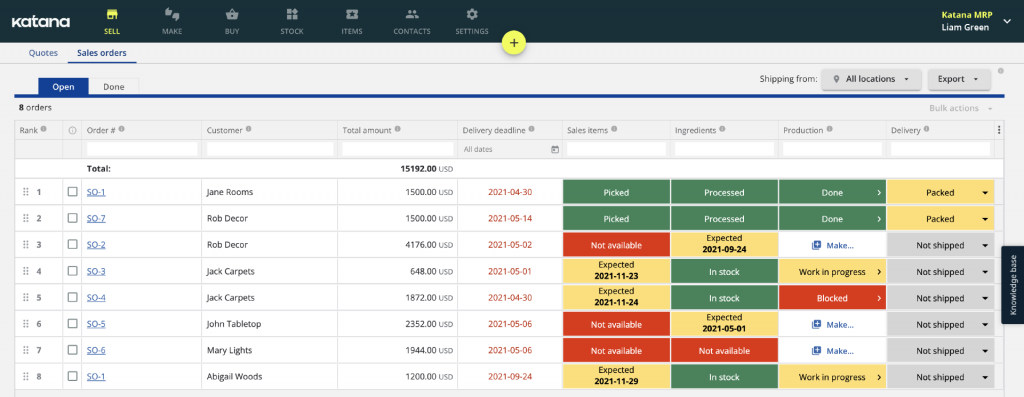

Using cycle inventory with your cloud inventory software

Cloud inventory systems can track customer demand, production schedules, and supplier lead times, providing inventory software features that give you total visibility and control.

This information can be used to generate accurate forecasts of cycle stock levels. Additionally, many systems include features like materials requirements planning and capacity requirements planning, which can help businesses optimize their production schedules and minimize inventory levels.

Track cycle inventory with Katana

Achieving and maintaining an accurate cycle inventory is critical for any business that manufactures products or sells goods. By understanding the definition, the factors that impact it, and how to forecast it correctly, companies can save money on storage costs and avoid the costly consequences of stockouts.

The right cloud inventory platform can make a big difference in achieving this goal. A good system will have features like lot tracking, expiration date management, and real-time inventory updates that can help ensure cycle inventory is always accurate.

Katana’s cloud inventory software makes inventory management easy and integrates with software you know and love to give you an end-to-end overview of all business operations.